- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongying

-

Dimension(L*W*H):

-

720*660*850mm

-

Weight:

-

1000 KG

-

Product name:

-

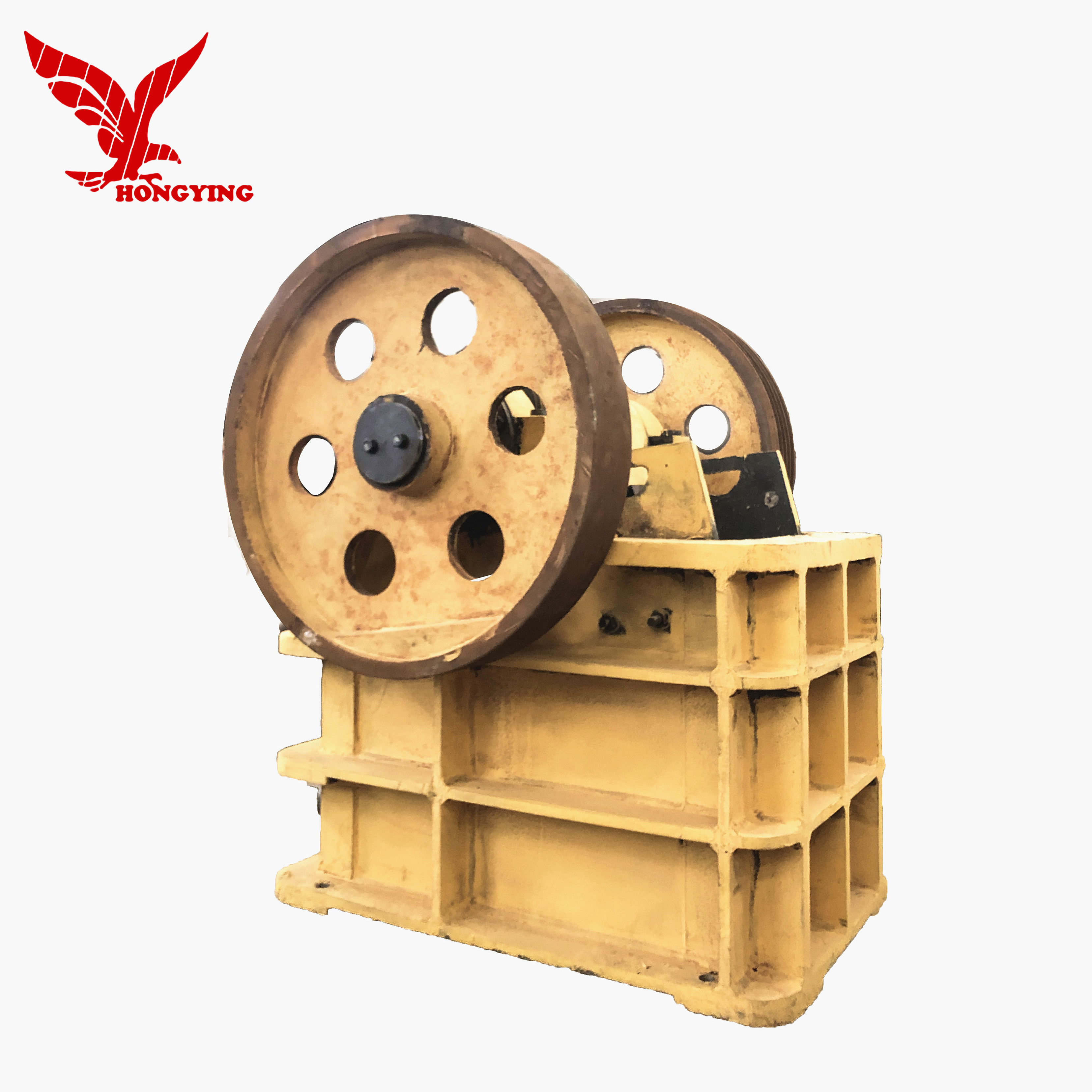

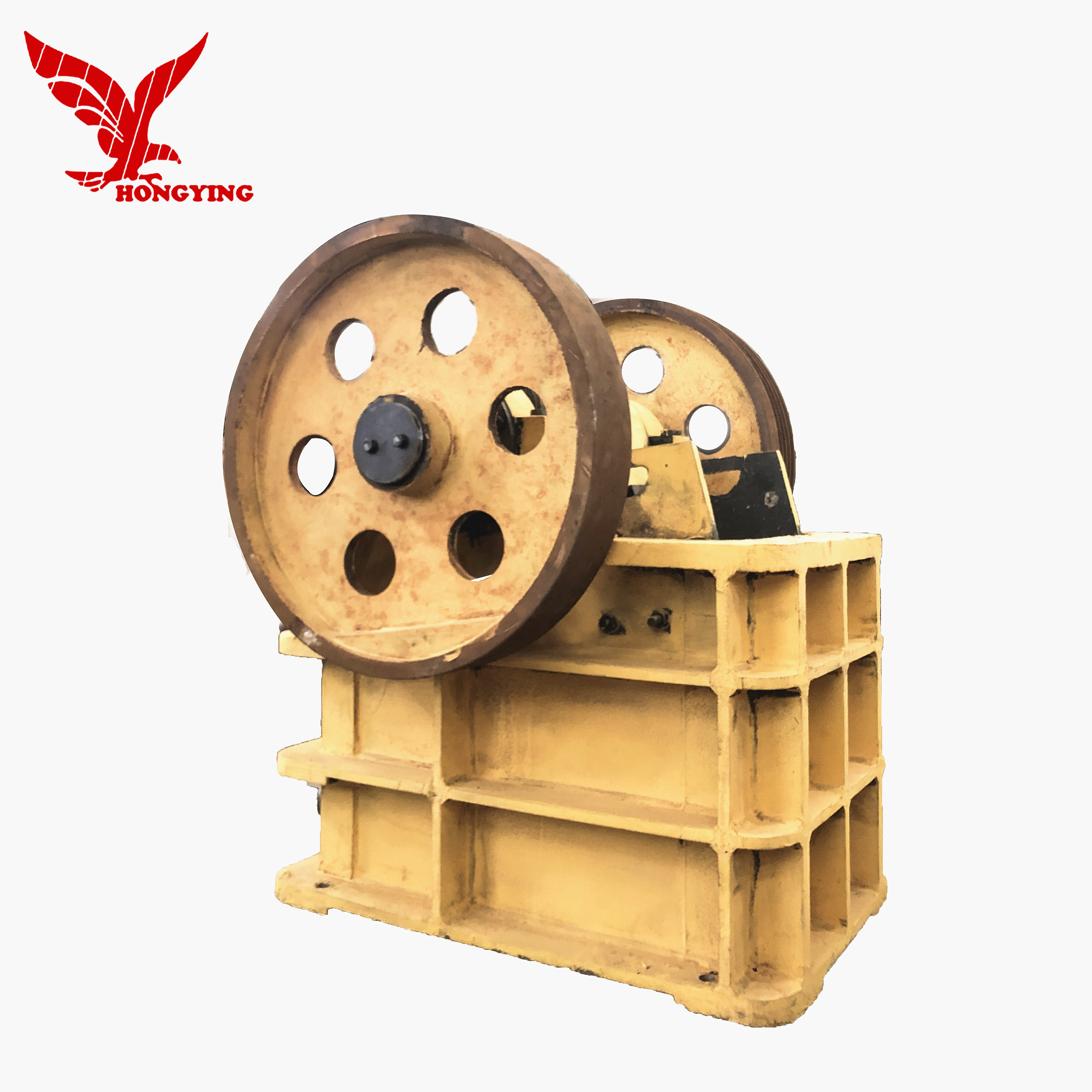

Laboratory Jaw Crusher mini crusher for stone

-

The Machines classification:

-

Jaw Stone Crusher

-

Raw material:

-

Stone,glass,

-

Color:

-

Customizable

-

After-sale service:

-

24-hour Customer Service Online

-

Spare parts supply:

-

Lifelong Time

-

Max feeding size:

-

125mm

-

Processed Materials:

-

High manganese steel

-

Factory visit:

-

Welcomed Warmly

-

Advantage:

-

Higher Efficiency

Quick Details

-

Application:

-

Mining

-

Capacity(t/h):

-

800

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongying

-

Dimension(L*W*H):

-

720*660*850mm

-

Weight:

-

1000 KG

-

Product name:

-

Laboratory Jaw Crusher mini crusher for stone

-

The Machines classification:

-

Jaw Stone Crusher

-

Raw material:

-

Stone,glass,

-

Color:

-

Customizable

-

After-sale service:

-

24-hour Customer Service Online

-

Spare parts supply:

-

Lifelong Time

-

Max feeding size:

-

125mm

-

Processed Materials:

-

High manganese steel

-

Factory visit:

-

Welcomed Warmly

-

Advantage:

-

Higher Efficiency

Laboratory Jaw Crusher mini crusher for stone

The jaw crusher is currently the most commonly used crusher in the world,which is divided into coarse and fine.Among them,the large and medium-sized Jaw crusher is one of our company's respresentative products,especially in design and production,which is in an absolute leading level in China.

Raw materials and Application:

This series of Jaw rougher crushers are widely used in mining,smelting,building materials,roads,railways,water conservancy,and chemical industries.

Main advantages:

This series of crushers has the characteristics of large crushing ratio,uniform product size,simple structure,reliable performance,easy maintenance and economical operation cost.

Working principle:

The working part of the jaw crusher is two jaws,one is a fixed jaw,which is fixed vertically on the front wall of the body,and the other is a movable jaw,which is inclined at an angle to form a large and small crushing cavity with the fixed jaw.The movable jaws periodically reciprocate against the fixed jaws,sometimes separated and sometimes close.When separated, the material enters the crushing chamber,and the finished product is discharged from the lower portion;when close,the material contained between the two jaws is crushed by bending,bending and splitting.

Notice:

The highest compressive strength of the crushed material is 320Mpa and can not exceed 320Mpa.The maximum speed of the crushed materials shall not exceed the specifications of the technical parameters.

| Model | Max Feeding Size(mm) | Output Size(mm) | Capacity(t/h) |

| PE 150*250 | 125 | 15-45 | 1.7-5.6 |

| PE 250*400 | 210 | 20-60 | 5-22 |

| PE 400*600 | 340 | 40-80 | 10-50 |

| PE 750*1060 | 630 | 80-180 | 122-223 |

| PE 1200*1500 | 1020 | 150-300 | 425-765 |

| PEX 100*600 | 80 | 10-40 | 1-8 |

| PEX 250*1000 | 210 | 15*50 | 20-50 |

| PEX 300*1300 | 250 | 15-60 | 45-110 |

Our workshop:

Packaging Details:

1.Standard export packing or according to customer's requirements.

2.If bulk purchasing,we will use standard container.

Delivery Details:

1.Lead time for mass production:within 3 days after received 30% deposit.

2.Delivery date:within 5 days after received balance payment.

3.After the confirmation of the order,the buyers should pay 30% deposit,the rest can be pay off in two weekdays before shipping the goods off.

Related products:

Hammer crusher:

Before-sale services:

(1)Guide customers to choose the best appliable machine type; provide the advanced,energy -saving and practical technological process.

(2)We are responsible for the process chart and design.

Sale services:

(1)Products must be inspected strictly before selling;

(2)In accordance with the agreements stipulated in the contract.

(3)We will organize delivery.

After-sale services:

(1)Our company will send professional engineers to guide with device installation,debugging and training operators until customers are fully satisfied.Moreover,we will design and manufacture products,according to the special requirements of customers.

(2)The quality guarantee period for machines is one year except the wearing parts.