- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huansheng

-

Dimension(L*W*H):

-

900*1800mm

-

Weight:

-

3400 KG

-

Product name:

-

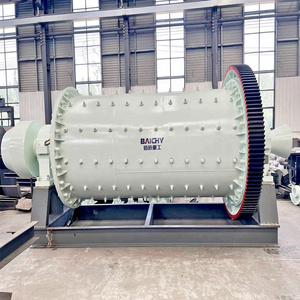

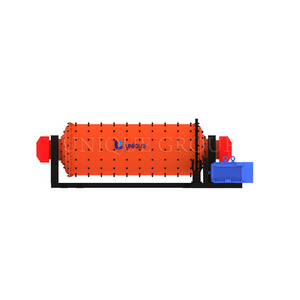

Continuous Ball Mill ball Mill Balls 2 Ton Ball Mill

-

Keywords:

-

Ball Mill Machine

-

Application:

-

Stone Powder Grinding

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Grinding Mining Stone

-

Color:

-

Customers' Requirements

-

Advantages:

-

High Efficiency Low Energy

-

Name:

-

Ball Mill

-

The Machines classification:

-

Ball Mill Grinding Equipment

-

Grinding media:

-

High Chrome Steel

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Capacity(t/h):

-

2 Ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huansheng

-

Dimension(L*W*H):

-

900*1800mm

-

Weight:

-

3400 KG

-

Product name:

-

Continuous Ball Mill ball Mill Balls 2 Ton Ball Mill

-

Keywords:

-

Ball Mill Machine

-

Application:

-

Stone Powder Grinding

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Grinding Mining Stone

-

Color:

-

Customers' Requirements

-

Advantages:

-

High Efficiency Low Energy

-

Name:

-

Ball Mill

-

The Machines classification:

-

Ball Mill Grinding Equipment

-

Grinding media:

-

High Chrome Steel

Products Description

Huansheng Mineral Gold Copper Ore Limestone Grinding Machine Gold Ore Ball Mill

Product Application:

Ball mill is the essential equipment for grinding after the crushing process, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Main Features:

1) This Ball mill machine changes the intrinsic grinding mill structure.

2) Its body and ground plank are an integral whole. So when fixing, it can be lowered on a plane surface once only.

3) Use double tiered roller axletree with the centripetal spherical surface as the support of the host axletree can reduce energy costs by 30%.

4) The intrinsic grille pattern forcing evacuation is instead controlled by the over-fall design. This can improve the milling of the granule and the quantity dealt with is reduced by 15-20%.

Huansheng Mineral Gold Copper Ore Limestone Grinding Machine Gold Ore Ball Mill

If you are interested in our products,please add my whatsapp:008615515534781

Specification

Working principle:

The

ball mill

is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber

through the quill shaft uniformly. There are ladder liners and ripple liners and different specifications of steel balls in the

chamber. The centrifugal force caused by the rotation of the barrel brings the steel balls to a certain height and impacts and

grinds the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

The

ball mill

produced by our company is a horizontal cylindrical rotating device, with outer gear transmission, two chambers, and a lattice-type ball mill.

The material enters the first chamber of the mill evenly and spirally from the feeding device through the feeding hollow shaft. There are ladder linings or corrugated linings in this chamber, and different specifications of grinding media - steel balls. When the rotating part rotates, The centrifugal force is generated to bring the steel ball to a certain height and then fall, which has a heavy impact and grinding effect on the material.

After the materials reach coarse grinding in the first chamber, they enter the second chamber through the single-layer partition plate. This chamber is equipped with a flat lining plate and contains steel balls for further grinding the materials. The powdery material is discharged through the discharge grate plate to complete the grinding operation.

Huansheng Mineral Gold Copper Ore Limestone Grinding Machine Gold Ore Ball Mill

If you are interested in our products,please add my whatsapp:008615515534781

Product Parameters

|

Model

|

Cylinder Rotating Speed (r/min)

|

Ball weight (t)

|

Feeding Size (mm)

|

Discharging Size (mm)

|

Capacity (t/h)

|

Power (kw)

|

|

900×1800

|

38

|

1.5

|

≤20

|

0.075-0.89

|

0.65-2

|

18.5

|

|

900×3000

|

38

|

2.7

|

≤20

|

0.075-0.89

|

1.1-3.5

|

22

|

|

1200×2400

|

35

|

4.6

|

≤25

|

0.075-0.6

|

1.6-5.8

|

37

|

|

1200×4500

|

35

|

5.5

|

≤25

|

0.074-0.4

|

1.6-5.8

|

55

|

|

1500×3000

|

29

|

9

|

≤25

|

0.074-0.4

|

2-7

|

75

|

|

1500×5700

|

29

|

17

|

≤25

|

0.074-0.4

|

3.5-6

|

110-130

|

|

1830×4500

|

25.4

|

15

|

≤25

|

0.074-0.4

|

4.5-12

|

155

|

|

1830×6400

|

24.1

|

21

|

≤25

|

0.074-0.4

|

6.5-15

|

210

|

|

1830×7000

|

24.1

|

23

|

≤25

|

0.074-0.4

|

7.5-17

|

245

|

|

2100×4500

|

23.7

|

24

|

≤25

|

0.074-0.4

|

8-43

|

245

|

|

2100×7000

|

23.7

|

26

|

≤25

|

0.074-0.4

|

8-48

|

280

|

|

2200×4500

|

21.5

|

27

|

≤25

|

0.074-0.4

|

9-45

|

280

|

|

2200×6500

|

21.7

|

35

|

≤25

|

0.074-0.4

|

14-26

|

380

|

|

2200×7000

|

21.7

|

35

|

≤25

|

0.074-0.4

|

15-28

|

380

|

|

2400×3000

|

21

|

23

|

≤25

|

0.074-0.4

|

30-50

|

245

|

|

2400×4500

|

21

|

30

|

≤25

|

0.074-0.4

|

40-60

|

320

|

|

2700×3600

|

20.7

|

40

|

≤25

|

0.074-0.4

|

45-80

|

430

|

|

2700×4500

|

20.7

|

48

|

≤25

|

0.074-0.4

|

50-90

|

430

|

|

2700×13000

|

20.7

|

60

|

≤25

|

0.074-0.4

|

50-90

|

630

|

|

3200×4500

|

18

|

65

|

≤25

|

0.074-0.4

|

--

|

800

|

APPLICATION

Our Advantages

1. High production capacity and crushing ratio;

2. Low power consumption, uniform particle size;

3. Simple structure, easy to operate;

4. Low investment cost, big profit;

5. Perfect services, both before-sales services and after-sales services.

If you are interested in our products,please add my whatsapp:008615515534781

Packing and Delivery

Recommend Products

Hot Searches