- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

sade

-

Weight (KG):

-

5000

-

Power (kW):

-

5

-

wire diameter:

-

3-8mm 5-12mm

-

width:

-

2.5m

-

hole size:

-

100*100-300*300mm

-

keywords:

-

concrete reinforce welded mesh panels welding machine

-

Welding speed:

-

max 85times/min

-

Voltage:

-

380v,50hz,3p

-

Finished product:

-

roll or sheet

-

Wire materials:

-

low carbon steel wire

-

Product name:

-

welded wire mesh machine

Quick Details

-

Wire Diameter (mm):

-

5 - 12 mm

-

Production Capacity:

-

100times/min

-

Place of Origin:

-

China

-

Model Number:

-

sade

-

Weight (KG):

-

5000

-

Power (kW):

-

5

-

wire diameter:

-

3-8mm 5-12mm

-

width:

-

2.5m

-

hole size:

-

100*100-300*300mm

-

keywords:

-

concrete reinforce welded mesh panels welding machine

-

Welding speed:

-

max 85times/min

-

Voltage:

-

380v,50hz,3p

-

Finished product:

-

roll or sheet

-

Wire materials:

-

low carbon steel wire

-

Product name:

-

welded wire mesh machine

|

|

|

|

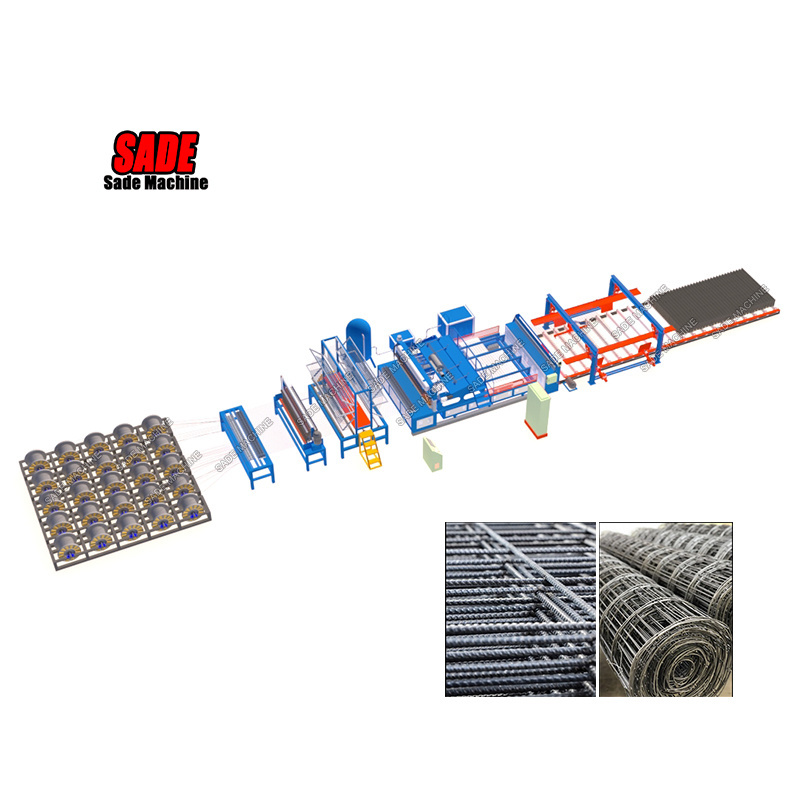

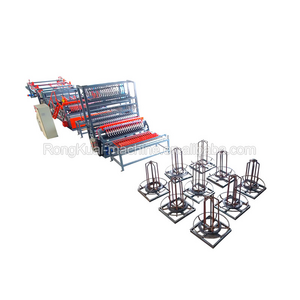

This is our new developed pneumatic welding machine .The machine adopts synchronons control technique, welding time and sub-control welding is composed of PLC program system. The mesh produced can be used for fences, high-speed railway fences, construction mesh, chicken mesh etc.

|

Items |

Description |

|

Finish Mesh Type |

wire mesh fence pannel/building construction mesh |

|

Welding Wire Diameter |

Φ3-6/4-8/5-12(mm) |

|

Welding Aperture |

50*50-300*300(mm) |

|

Welding Width |

2500(mm) |

|

Number of Electrodes |

48 |

|

Welding Speed |

80-100times/min |

|

Power |

Three phase 380V±10% 50HZ |

|

Welding Power |

50HZ/380V(transformer capacity ≥125KVA) |

|

Rated Voltage |

AC380V 50HZ |

|

Feeding wire type |

pre cutted wire |

|

Weight |

6T |

|

Overall Dimension |

10x3.0x2.0m |

|

Curver Making |

Online curver |

1.This machine adopts Japan Mitsubishi brand electronic synchronous control technique, welding time and sub-control welding are all composed of digital integrated circut, which has high control accuracy, stable performance, firm welding spots and without burned mark.

2.The welding speed is fast and the operation is simple and easy to master.

3.The weft matched with the accurate weft cutting device and accurate positioning device, ensures the weft at the same length and without being out.

4. The mesh drawing system is controlled by motor which improved the precision of mesh opening size, meanwhile the line wire and the weft wire spacing are adjustable.