- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

50-60HZ

-

Welding Area:

-

20-63

-

Dimensions:

-

45*36*38

-

Use:

-

ppr welding machine

-

Weight (KG):

-

7 KG

-

Power (kW):

-

1000

-

After sales Service Provided:

-

Overseas third party support available

-

Power:

-

800W

-

Presszure rate:

-

Pn25

-

certificate:

-

CE Certificate with high quality

-

Application:

-

for Hot Water and Cold Water Supply

-

PPR Fittings Packing:

-

Small PE bags inner Cartoun Outside

-

After Warranty Service:

-

Video technical support

-

Showroom Location:

-

None

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Fosite

-

Voltage:

-

220V+-10%

-

Frequency:

-

50-60HZ

-

Welding Area:

-

20-63

-

Dimensions:

-

45*36*38

-

Use:

-

ppr welding machine

-

Weight (KG):

-

7 KG

-

Power (kW):

-

1000

-

After sales Service Provided:

-

Overseas third party support available

-

Power:

-

800W

-

Presszure rate:

-

Pn25

-

certificate:

-

CE Certificate with high quality

-

Application:

-

for Hot Water and Cold Water Supply

-

PPR Fittings Packing:

-

Small PE bags inner Cartoun Outside

-

After Warranty Service:

-

Video technical support

-

Showroom Location:

-

None

Plastic pipe welding machine/ electrofusion machine

Plastic pipe welding machine/ electrofusion machine

Its equiped 6 moulds of its diameter size:20-63mm

we can offer good quality with competive price

(1.) welding connector

(2.) Plastic pipe welding machine

(3.) Quality is excellent and professional.we have the ce certification

(4.) Voltage: 220V±10%,frequency:50/60Hz; Power: 800W

(5.) Component: 20-63MM sockets, screws, Screwdriver,hexagonal spanners.Using Manual.standing.

(6.) The size of the moulds:20mm,25mm,32mm,40mm 50mm 63mm

(8.) Pack list: 5pcs/CTN, 21/20KGS (G.W./N.W.), MEAS/CTN:45*36*38CM

(9.) Up to 500pcs, appointed color box and instruction.

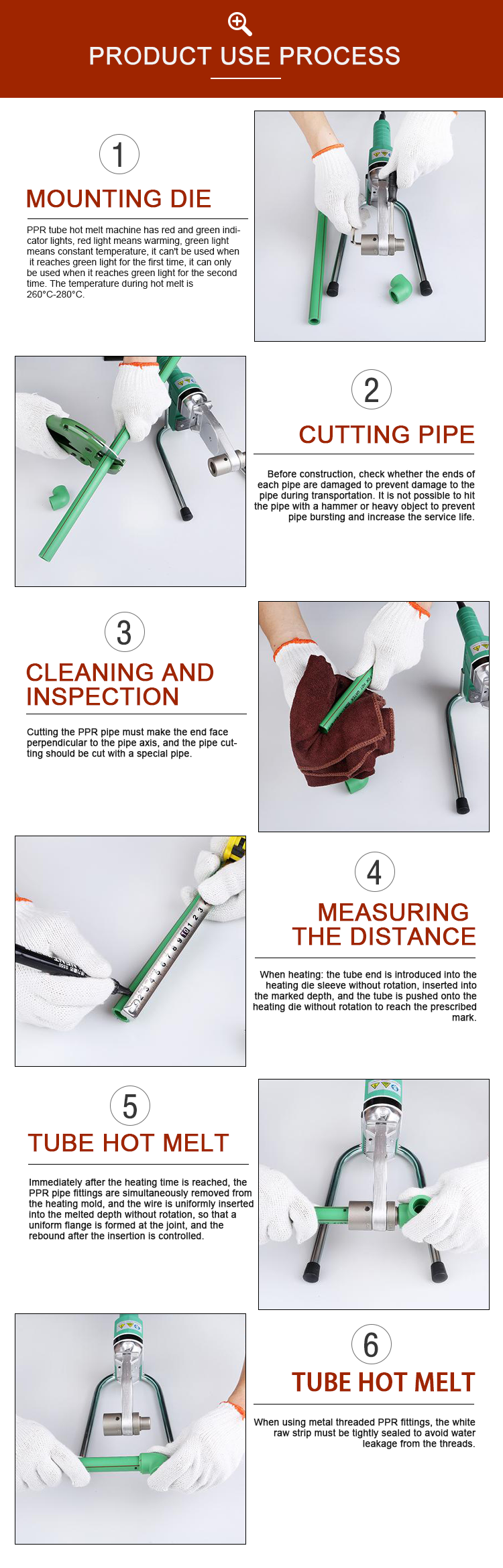

Usage

1. Fixed install heating-side welding head, the welding device placed on the shelves, according to specifications required to install the corresponding heating pipe die head, and pull tight with a hex generally small in the preceding paragraph, a large back-end.

2. Switch on the power (note the power supply must be protected with a ground line), according to the corresponding models of the machine to the instruction attention to light changes, until the welding temperature control device to enter the work state, can be started.

3. With vertical cutting device to cut off pipe tube, pipe and fittings will also promote the welding device with no moving within the die, as required for operation. Immediately after the heating time to reach pipes and fittings removed from the die head at the same time, rapidly rotating non-uniform insert directly to the desired depth, to form a uniform flange joints.

2021 Exhibition in Beijing

please inquire us for more information