- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

customized

-

Mould Life:

-

250000-300000shots

-

Keyword:

-

Mould Maker

-

Usage:

-

Stamping Work

-

Feature:

-

Long Service Life

-

process:

-

slow cutting

-

After-sale service:

-

Overseas service provide

-

Surface treatment:

-

Polishing

-

Application:

-

Auto Parts Mold

-

Design software:

-

CAD

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

bescomt

-

Model Number:

-

customized

-

Mould Life:

-

250000-300000shots

-

Keyword:

-

Mould Maker

-

Usage:

-

Stamping Work

-

Feature:

-

Long Service Life

-

process:

-

slow cutting

-

After-sale service:

-

Overseas service provide

-

Surface treatment:

-

Polishing

-

Application:

-

Auto Parts Mold

-

Design software:

-

CAD

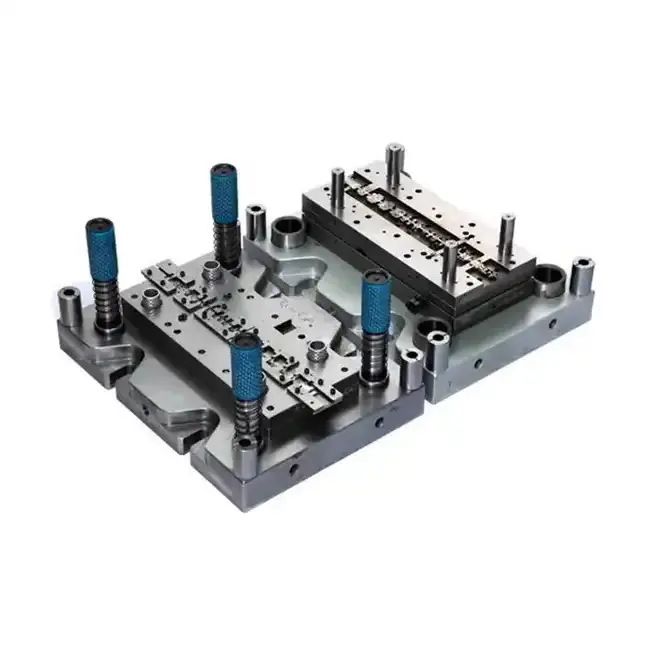

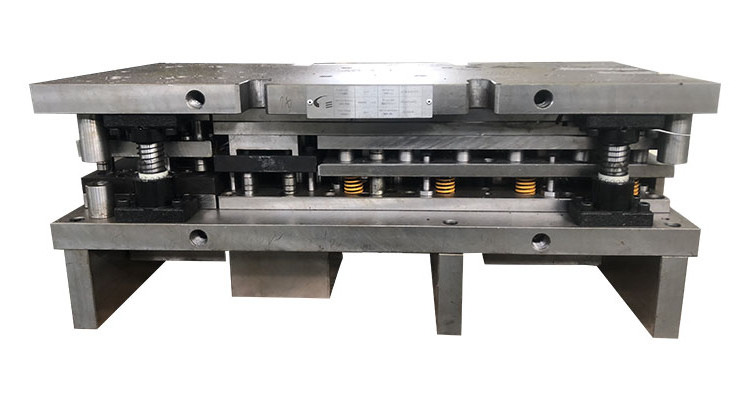

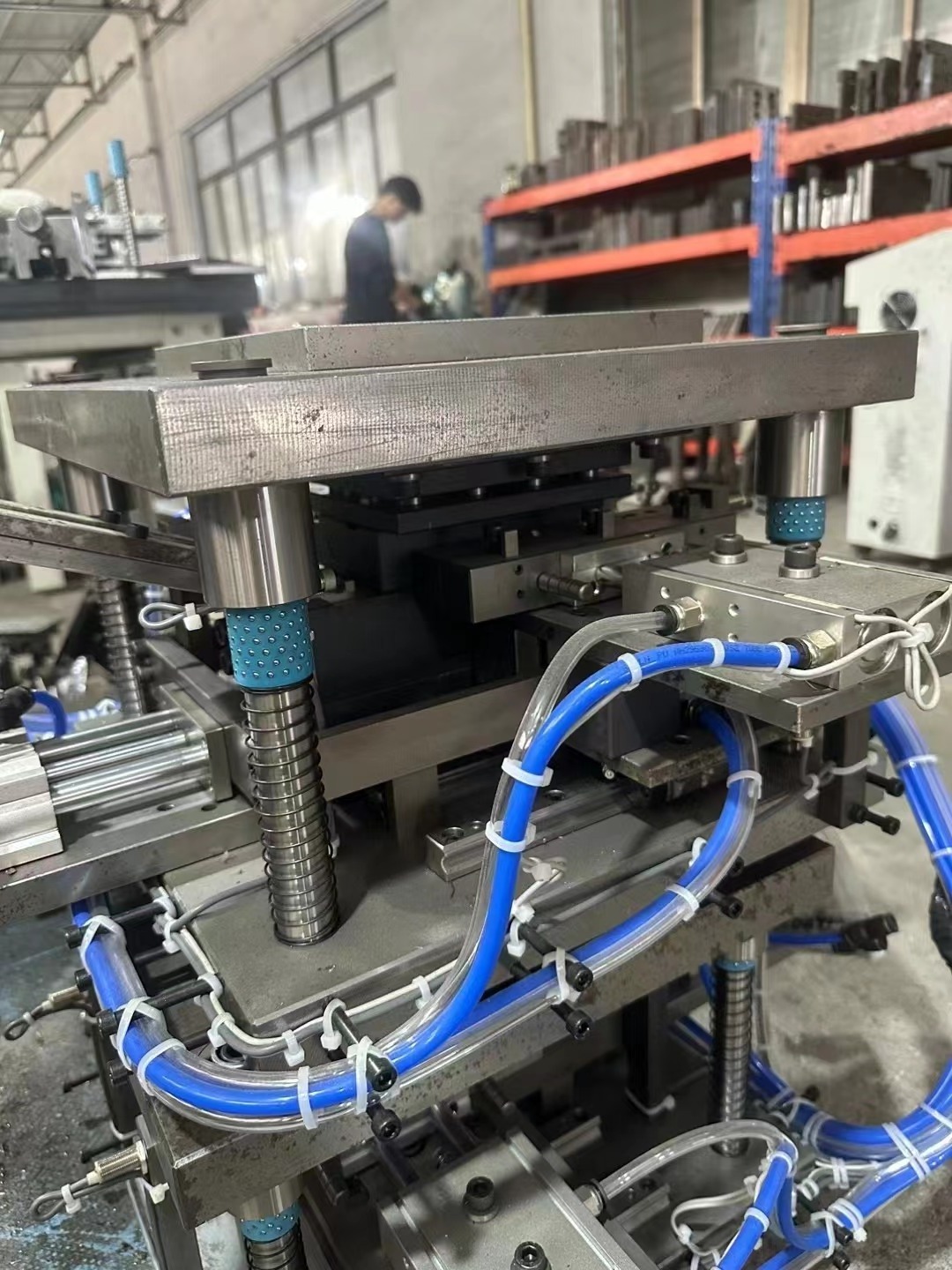

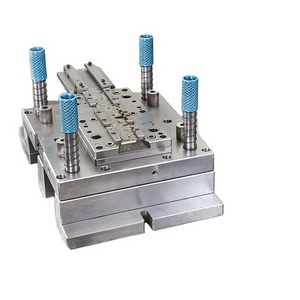

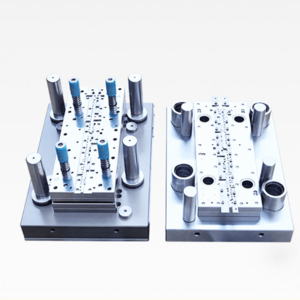

Introduce:

Punch die is corresponding to the punch "accessories", the workpiece in the punch press and mold resistance under the joint action of plastic deformation to complete the processing process, punch die is an indispensable part of the stamping process, punch die precision to a large extent determines the workpiece processing accuracy.

|

Product name

|

power press dies/mould

|

|

Material of die

|

D2, SKH-9, SKD11,A3,SKD61

|

|

Design software

|

Auto CAD, PRO/E.

|

|

Die type

|

Stamping press moulds, stamping die, punching die, sheet metal mould , progressive die, terminal die, single die, double die

|

|

Drawing format

|

igs, stp , prt, pdf, dwg

|

|

Die life

|

1,000,000-3,000,000 shots

|

|

First trial

|

30-45 days after mold drawing confirmed

|

|

Mould design

|

Design the mould structure drawing according to your product drawing or sample.

|

|

Quality confirm

|

You will confirm our stamping die quality according to sample, if you need to adjust the product structure,we can help you to

change it further. |

Besco company is one of the largest professional precision mold manufacturers, set sales, technology, service in one, the company USES advanced production equipment and modern management, the production of all kinds of molds in the industry to reach the first-class level, covering hardware, electronics, home appliances, food packaging and other industries.Adhering to the principle of "customer first, quality first", the company has won wide recognition from all walks of life with high-standard products and high-quality services, and has established long-term cooperative relations with customers

1.Terms

Delivery time:45 days after order

Packaging:Standard foreign trade wooden box export packaging Payment methods: Western Union or PayPal or TT:30% deposit in

advance,70% balance before shipment against the copy of B/L.

Warranty pertod:2 years

Technical service : available(online + offline)

Operation & maintenance manual(English Version)available

2.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis

/Conformance; Insurance; Origin, and other export documents where required.

3.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

4.Warranty Policy

The guarantee covers the main parts of the machine, excluding wearing parts. PARTS DELIVERY Within 5 days by DHL/ Fexed .During

the warranty periodfree maintenance and replacement parts available if any quality problem under regular operation.(except for improper operation or man-made damage) .

Hot Searches