- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000

-

Weight (KG):

-

1050 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GTOP

-

Voltage:

-

220V/380V customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

25 kW

-

Product name:

-

Homogenizing Emusifying Machine

-

After-sales Service Provided:

-

Engineers Provided

-

Function:

-

Mixing Raw Material

-

Heating method:

-

Electric Steam Heating

-

Motor:

-

ABB,Siemens ect

-

Feature:

-

High Efficency Mixing Machine

-

Homogenizer:

-

Frequency Inverter

-

Control:

-

PLC+ Touch Screen

Quick Details

-

Barrel Volume (L):

-

5-5000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 63 r.p.m

-

Max. Loading Capacity:

-

5000

-

Weight (KG):

-

1050 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GTOP

-

Voltage:

-

220V/380V customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

25 kW

-

Product name:

-

Homogenizing Emusifying Machine

-

After-sales Service Provided:

-

Engineers Provided

-

Function:

-

Mixing Raw Material

-

Heating method:

-

Electric Steam Heating

-

Motor:

-

ABB,Siemens ect

-

Feature:

-

High Efficency Mixing Machine

-

Homogenizer:

-

Frequency Inverter

-

Control:

-

PLC+ Touch Screen

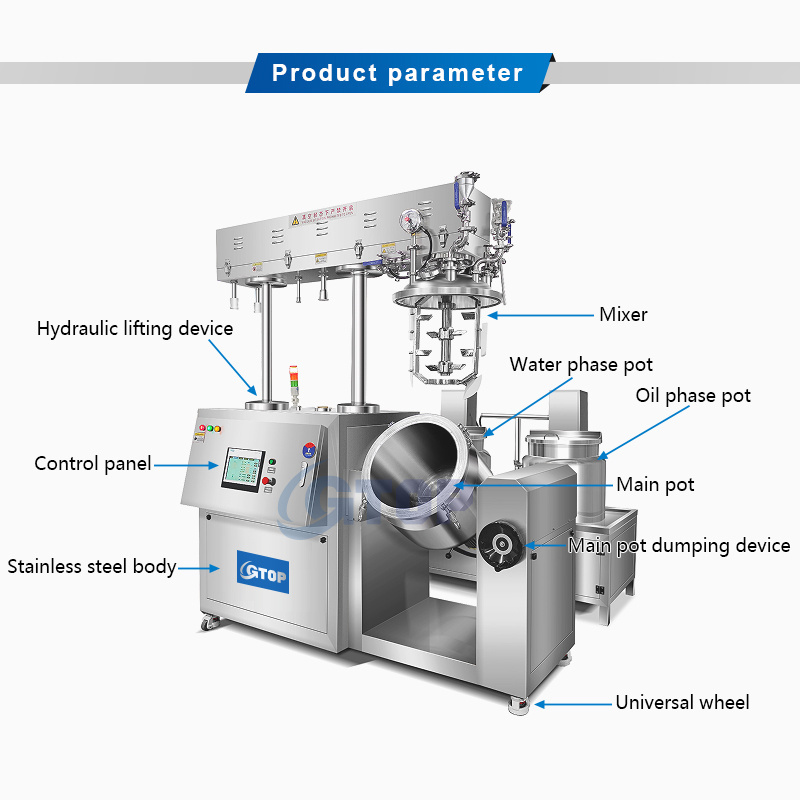

The machine is suitable for the production of various kinds of paste, cream products in cosmetic factory and pharmaceutical

factory. Especially designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpastes,

etc. having extremely small particles for chemical, cosmetics, pharmaceutical and food industries.

Features and Advantages

1. The vacuum emulsifying mixer machine is composed of water pot, oil pot, emulsifying pot, operation platform, vacuum system,

lifting system etc.

2. Material can be heating or cooling according to technological requirements. The heating methods such as steam or electric

heating can be selected according to customer's requirements.

3. The tank body are made of the high quality stainless steel and all contact parts adopt the SUS316L stainless steel. The tank

body and pipe are subjected to mirror polishing.

4. Various forms of blending vanes are suitable for production of different types of production of products.

5. The wall scraping mixer adopts frequency converter to adjust the mixing speed, suitable for various products based on clients'

requirements.

6. The mixing system includes single-way mixing, double-way mixing and helical ribbon mixing. The lifting systems include

single-cylinder lifting and double-cylinder lifting. According to your request, we can customized the suitable machine for you.

7. Vacuum defoaming can make the material reach requirement of aseptic. It adopts the vacuum to suck the material especially for

the powder material, which can avoid the dust.

8. It is fully in accordance with the GMP standard production and passed CE certification.

factory. Especially designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpastes,

etc. having extremely small particles for chemical, cosmetics, pharmaceutical and food industries.

Features and Advantages

1. The vacuum emulsifying mixer machine is composed of water pot, oil pot, emulsifying pot, operation platform, vacuum system,

lifting system etc.

2. Material can be heating or cooling according to technological requirements. The heating methods such as steam or electric

heating can be selected according to customer's requirements.

3. The tank body are made of the high quality stainless steel and all contact parts adopt the SUS316L stainless steel. The tank

body and pipe are subjected to mirror polishing.

4. Various forms of blending vanes are suitable for production of different types of production of products.

5. The wall scraping mixer adopts frequency converter to adjust the mixing speed, suitable for various products based on clients'

requirements.

6. The mixing system includes single-way mixing, double-way mixing and helical ribbon mixing. The lifting systems include

single-cylinder lifting and double-cylinder lifting. According to your request, we can customized the suitable machine for you.

7. Vacuum defoaming can make the material reach requirement of aseptic. It adopts the vacuum to suck the material especially for

the powder material, which can avoid the dust.

8. It is fully in accordance with the GMP standard production and passed CE certification.

Specification

|

Model

|

Capacity(L)

|

Mixing power(kw)

|

Mixing speed(r/min)

|

Homogenizing power(kw)

|

Homogenizing speed(r/min)

|

Heating method

|

||||||

|

GT-E-20

|

20

|

0.37

|

0-63

|

0.75

|

0-3000

|

Steam heating or electric heating(optional) |

||||||

|

GT-E-50

|

50

|

0.37

|

0-63

|

2.2

|

0-3000

|

|

||||||

|

GT-E-100

|

100

|

1.5

|

0-63

|

3

|

0-3000

|

|

||||||

|

GT-E-150

|

150

|

1.5

|

0-63

|

3

|

0-3000

|

|

||||||

|

GT-E-200

|

200

|

1.5

|

0-63

|

4

|

0-3000

|

|

||||||

|

GT-E-350

|

350

|

2.2

|

0-63

|

4

|

0-3000

|

|

||||||

|

GT-E-500

|

500

|

2.2

|

0-63

|

5.5

|

0-3000

|

|

||||||

|

GT-E-1000

|

1000

|

5.5

|

0-63

|

9

|

0-3000

|

|

||||||

|

GT-E-2000

|

2000

|

5.5

|

0-63

|

11

|

0-3000

|

|

||||||

|

Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shallprevail.

|

|

|

|

|

|

|

||||||

Hot Searches