- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

CNMI

-

Model Number:

-

HL310

-

Type:

-

Deep Pour Epoxy Resin

-

Product name:

-

Deep Pour Epoxy Resin

-

Application:

-

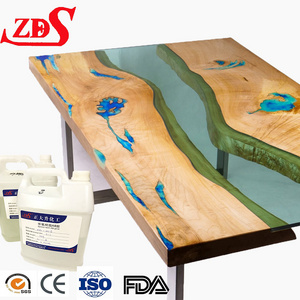

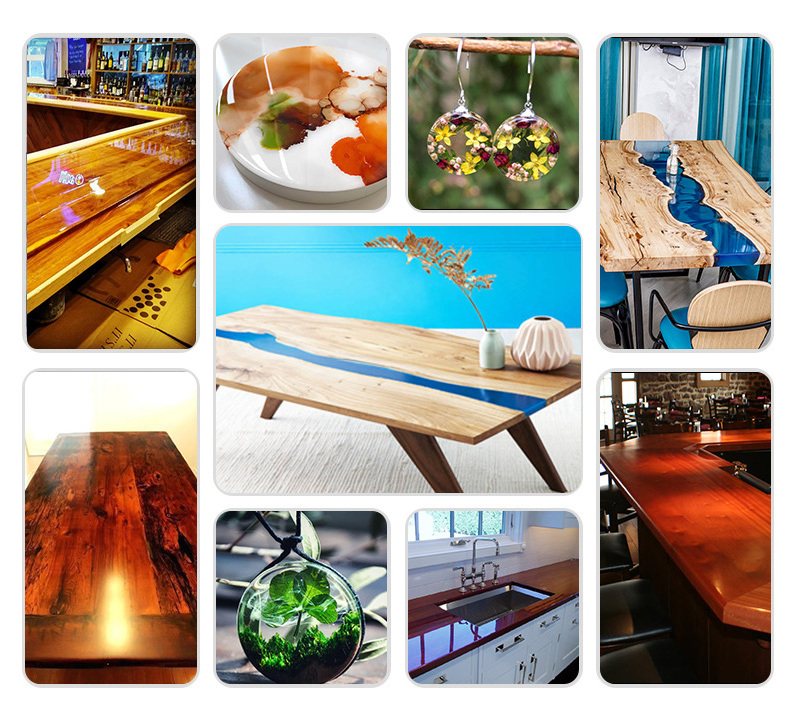

Woodworking, DIY, Art Craft

-

Color:

-

Pure Transparent

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

-

Shelf life:

-

12 Months

-

Component:

-

Epoxy Resin and Hardener

-

Mixing Ratio:

-

3:1

-

Keywords:

-

Deep Pour Epoxy Resin

-

Appearance:

-

Liquid

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

Deep Pour Epoxy Resin

-

MF:

-

C6H7NO2

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

CNMI

-

Model Number:

-

HL310

-

Type:

-

Deep Pour Epoxy Resin

-

Product name:

-

Deep Pour Epoxy Resin

-

Application:

-

Woodworking, DIY, Art Craft

-

Color:

-

Pure Transparent

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

-

Shelf life:

-

12 Months

-

Component:

-

Epoxy Resin and Hardener

-

Mixing Ratio:

-

3:1

-

Keywords:

-

Deep Pour Epoxy Resin

-

Appearance:

-

Liquid

CNMI Epoxy Resin Crystal Clear AB Glue Transparent Epoxy Resin Kit HL310 3:1 Liquid Deep Pour Epoxy Resin for Epoxy Paperweight

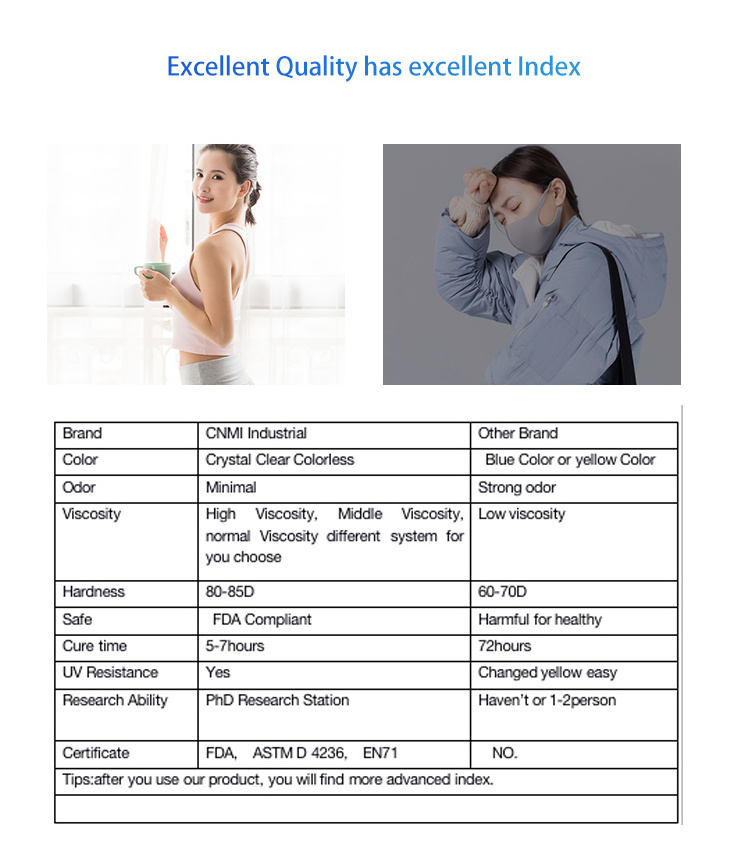

The most advanced epoxy coating on the market!

The biggest Producer For Epoxy Resin and Hardener in China!

Modified Epoxy Resin and Hardener from Raw Material, Not only Physical Mixing!

CNMI Industrial Epoxy Resin is the most advanced level of shine, gloss, reflectivity, clarity and depth, and it locks in those optical qualities forever. The most sophisticated system of synthetic polymeric-based protection available. Our Commercial-grade epoxy HL310 is

engineered specifically for

casting and pouring.

CNMI Industrial Epoxy Resin is the most advanced level of shine, gloss, reflectivity, clarity and depth, and it locks in those optical qualities forever. The most sophisticated system of synthetic polymeric-based protection available. Our Commercial-grade epoxy HL310 is

engineered specifically for

casting and pouring.

|

Specification

|

Epoxy Resin |

HL310-A |

Standard |

|

Appearance |

Colorless Transparent Liquid |

------- |

|

|

Viscosity (mPa.s 25℃) |

1000-2000 |

GB/T 22314-2008 |

|

|

Epoxy equivalent (g/eq) |

195-205 |

GB/T 4612-2008 |

|

|

Hardener |

HL310-B |

Standard |

|

|

Appearance |

Colorless Transparent Liquid |

-------- |

|

|

Viscosity (mPa.s 25℃) |

20-100 |

GB/T 22314-2008 |

|

|

Note:Typical performance should not be considered as product specifications |

|||

|

Mixing and Processing |

The resin system shall be mixed in the following proportions |

||

|

HL310-A |

HL310-B |

||

|

Weight Ratio |

100 |

33 |

|

|

Volume Ratio |

100 |

30 |

|

|

Mix Viscosity (mPa.s 25℃) |

300-500mPa.s |

||

|

Processing time 25℃ |

60-120min |

||

|

Cure Condition |

25℃/8-10hours/ 60℃ 2-4hours |

||

Epoxy Resin HL310 for Casting and Pouring River Table and Jewelry, Mix Ratio is 3:1 by Weight.

|

100% VOC free. Virtually odorless.

Use in odor-sensitive areas such as wineries, restaurants, kitchens, or confined spaces. CNMI Industry epoxy will out perform, out protect, outshine and outlast anything on the market |