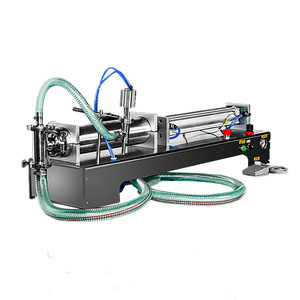

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤0.02%

-

Voltage:

-

380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

VIC

-

Dimension(L*W*H):

-

1800*1265*2470mm

-

Weight:

-

780 KG

-

After-sales Service Provided:

-

1year

-

Filling volume:

-

0.5-5L

-

Capacity:

-

600-800Barrel/hour

-

Precision:

-

≤0.2%

-

Pressure:

-

0.5-0.8MPa

-

Gas consumption:

-

0.96m³/min

-

Transit tank volume:

-

0.38m³

-

Conveyor L:

-

9.51m

-

Chain box H:

-

215*200MM

-

Chain width:

-

114.3mm

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≤0.02%

-

Voltage:

-

380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

VIC

-

Dimension(L*W*H):

-

1800*1265*2470mm

-

Weight:

-

780 KG

-

After-sales Service Provided:

-

1year

-

Filling volume:

-

0.5-5L

-

Capacity:

-

600-800Barrel/hour

-

Precision:

-

≤0.2%

-

Pressure:

-

0.5-0.8MPa

-

Gas consumption:

-

0.96m³/min

-

Transit tank volume:

-

0.38m³

-

Conveyor L:

-

9.51m

-

Chain box H:

-

215*200MM

-

Chain width:

-

114.3mm

25TPD Liquid filling machine sealing machine water packing machine full automatic edible oil filling line

25TPD Liquid filling machine sealing machine water packing machine full automatic edible oil filling line General flow chart reference:

Manual bottle placing--oil filling—machine capping—labeling machine

25TPD Liquid filling machine sealing machine water packing machine full automatic edible oil filling line core advantages

1.1 Specs switchover

The up, down, left and right directions of the oil nozzle can be adjusted by the hand wheel. The position of the wheel is user-friendly and easy to operate, which can realize the operation of quickly changing specifications. Each filling head can operate independently. According to the size of its own output, the computer can flexibly set the number of filling heads to be activated.

There are six internal formulas to choose to meet the requirements of different oil products and different specifications. There is no need to repeatedly set the adjustment parameters. When you need to adjust the parameters, you only need to call the corresponding recipe, and the operation is faster and more convenient.

1.2 Oil switchover

The built-in transfer tank and built-in power make it easier to completely empty every corner of the filling machine pipeline. After the work is completed, no need to clean the line.

1 .3 Drop oil recovery

The vacuum suction system is adopted, and the residual oil from the nozzle after filling is directly collected into the transparent oil return tank, which is convenient for collecting residual oil and visualizing the liquid level. The oil return tank has an automatic oil discharge function. At the end of each shift, the vacuum suction system is automatically opened to prevent the return tank from being full and affecting the suction effect.

1.4 Flowrate control

Abandoning the traditional two-speed valve design, the frequency converter is used to control the filling speed, first fast and then slow, and two-speed filling is implemented to ensure that the filling and filling speed is fast in the early stage, and no oil splashes or spills in the later stage. This function is the basic function of oil filling machine.

1 .5 Four-column reinforced crawler capping machine

On the basis of the traditional crawler-type capping machine, the advantages and disadvantages are avoided, and the automatic adjustment of the handwheel screw is used instead of the disassembly screw adjustment method, which solves the complex and tedious problem of adjusting the height of the capping machine. precise. At the same time, the structure of the capping machine is also improved, which solves the problem that the capping time is long, which may easily cause the crawler part of the capping machine to loosen and lift up. The whole machine capping quickly, without noise, will not cause extrusion and deformation of the bottle body, no air pressure phenomenon.

1.6 Design of transfer tank for filling machine

There is no need for the customer to prepare the transfer tank by himself. The oil supply pump is automatically controlled by the liquid level switch. When the oil amount is lower than the set value, the pump automatically starts to supply oil, and when the oil amount reaches the set value, the pump automatically stops the oil supply to realize automatic liquid level compensation. The transfer tank is located at the top of the filling machine, with small changes in liquid level and stable pressure, ensuring that filling is not restricted and affected by external conditions such as the distance and height of the raw material tank, which maximizes the filling accuracy and saves costs for users. The transfer tank adopts the beam support design to ensure that the tank body can be firm and stable without deformation even under the pressure of the full tank. The oil inlet is deep into the bottom of the transfer tank, and the double outlet design is adopted, which can prevent the air in the transfer tank from mixing with the oil in the tank. The distance between the end of the oil inlet and the oil outlet is far away. If the oil itself has some air, the air can be removed to the maximum extent, so as to prevent the oil with gas entering the transfer tank from being pumped away by the metering pump immediately, resulting in inaccurate metering by the metering pump. The liquid level float adopts the design of primary and secondary double floats and double insurance. When the main float fails and cannot be used normally, the secondary float can automatically start to turn off the oil supply pump to prevent the oil supply pump from continuously supplying oil when the main float is damaged. Oil overflows the tank.

1.7 "One key correction" function

I f there is an error in the measurement and the oil is not ac curate, you can directly input the wrong weight data in the computer, and the computer can automatically calculate the correct data and automatically correct it. The function of the equipment itself to automatically calibrate the filling volume is a real "one-key correction", and there is no need to learn how to calculate parameters and other complicated operations.

1.8 Variable frequency double reducer

Double-section conveyor belt design, the front conveying starts and stops along with the filling, and the rear conveying keeps running, and the filling and subsequent capping, coding, etc. The speed of the two conveying sections can be adjusted independently and freely controlled.

1.9 Automatic oil tank

After each shift is completed, the oil tank will automatically pop up after the equipment is powered off. After the equipment is powered off, the vacuum suction cannot be started, resulting in dripping of residual oil and contamination of the conveyor belt.

Main Equipment Description:

I. Full auto oil filling machine (4 heads)

25TPD Liquid filling machine sealing machine water packing machine full automatic edible oil filling line Main specs a bout the liquid fillig machine:

|

item Spec |

specs |

|

spec |

4 heads high precision full auto oil filling machine |

|

Filling volume |

0.5—5L |

|

Capacity |

1300—1500 barrel/hour(5L) |

|

Precision |

≤0.2% |

|

Voltage |

380V±10% 50HZ |

|

Pressure |

0.5—0.8MPa |

|

Gas consumption |

0.96m³/min(buyer prepare 2m³ air storage tank) |

|

Power |

5.05kw |

|

Size |

1800×1265×2470mm |

|

Transit tank volume |

0.38m³ |

|

Chain width |

114.3mm |

|

Conveyor L |

9.51m |

|

Chain box H |

215×200mm |

|

Working H |

1000mm |

|

Filling machine weight |

780kgs |

Main association parts:

Chain conveyor:

1. The conveyor belt is a double-segment chain belt, which is divided into a filling conveyor belt and a capping and coding conveyor belt. The former is stop-and-go, and the latter is constant-turn and non-stop.

2. The filling conveyor belt adopts frequency conversion speed regulation, and the start and stop of the conveyor belt are buffered to ensure smooth conveying, and prevent the phenomenon of inverted bottles and oil splashing.

3. Metal tripod, strong and durable, not afraid of aging.

4. Large C guardrail, integral molding, wear-resistant and impact-resistant, compact in structure, stable in operation, anti-cold shrinkage, anti-oxidation

Crawler Capping Machine

1. The extrusion method is formed by the crawler conveying, so that the bottle and the cap are squeezed together to achieve the function of compressing the bottle cap, which will not cause extrusion and deformation to the bottle body, stable, no noise, and no air pressure phenomenon.

2. The speed of the capping machine is adjusted by the frequency converter, so that the capping and the conveying are synchronized, and the bottle is not inverted.

Inspection lightbox

1 . Stainless steel frame, beautiful and sturdy, anti-corrosion

2. Fixed installation, convenient and quick

3. High-permeability and environmental-friendly plastic curtain panel, high-brightness LED lights, improve detection efficiency

Filling head

1. The filling head is a split type independently developed, that is, the filling head and the cylinder are connected externally. This structure can be disassembled and replaced separately, and the maintenance is convenient.

2. The national standard parts are selected for the accessories, which is convenient for customers to purchase and replace nearby, shorten the maintenance time and reduce the maintenance cost.

3. Fast, medium and slow three-speed variable frequency filling, and the speed is adjustable to ensure no dripping during the filling process.

II. Linear self-adhesive labeling machine (single label)

Main specs:

|

item spec |

Main specs |

|

Capacity |

Max 2200 bottles/h, bottle dia and label size will influence the speed |

|

Applicable |

Below 5L,also can customize by bottle sample |

|

Lables |

width15—260mm,height 15—160mm |

|

Labeling requirements |

Rotate clockwise (left out), the distance between the labels is equal to 3mm, paper labels, white backing paper |

|

Power |

2KW 220V,50Hz |

|

Compressor |

5bar(if need) |

|

Size |

2430×1500×1500mm |

|

Weight |

320KG |

|

testing sample required |

each specs bottle 20pcs, label more than 1 roll |

Installation workshop reference:

Packaging:

All our package are standard fumigated wooden box, we need around 5 working days to finish the machine and ready to deliver. If want extra spare parts pls notify when place order.

Warranty time :

one year for main machine, except for easy weared parts.

Quality guarantee is one year. Spare parts we supply at factory cost lifetime.

We will be responsible for any broken which are caused by machine-self and quality problem, other situations which are caused by wrong operation, man-made problems etc will be in buyer’s response, and we will help to solve by video asap, if big problem we will send engineer to working site within 1 week.