- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Weight:

-

10000 KG

-

Dimension(L*W*H):

-

Actual Size

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

General Industrial Fields

-

Capacity:

-

1~5000m3/h

-

Advantage:

-

O2 N2 CO2 Alternate Production

-

Purity:

-

95%~99.9995%

-

Technology:

-

Cryogenic

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

feimeng

-

Production Rate:

-

99.5-99.995%

-

Voltage:

-

220V/380V/440V

-

Weight:

-

10000 KG

-

Dimension(L*W*H):

-

Actual Size

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

General Industrial Fields

-

Capacity:

-

1~5000m3/h

-

Advantage:

-

O2 N2 CO2 Alternate Production

-

Purity:

-

95%~99.9995%

-

Technology:

-

Cryogenic

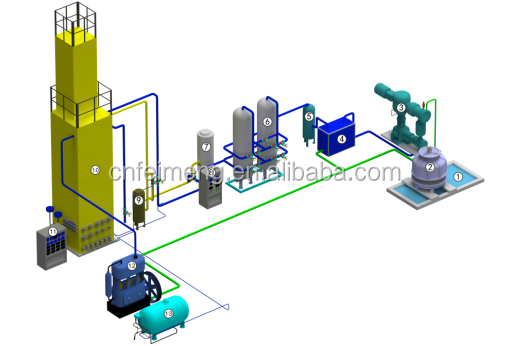

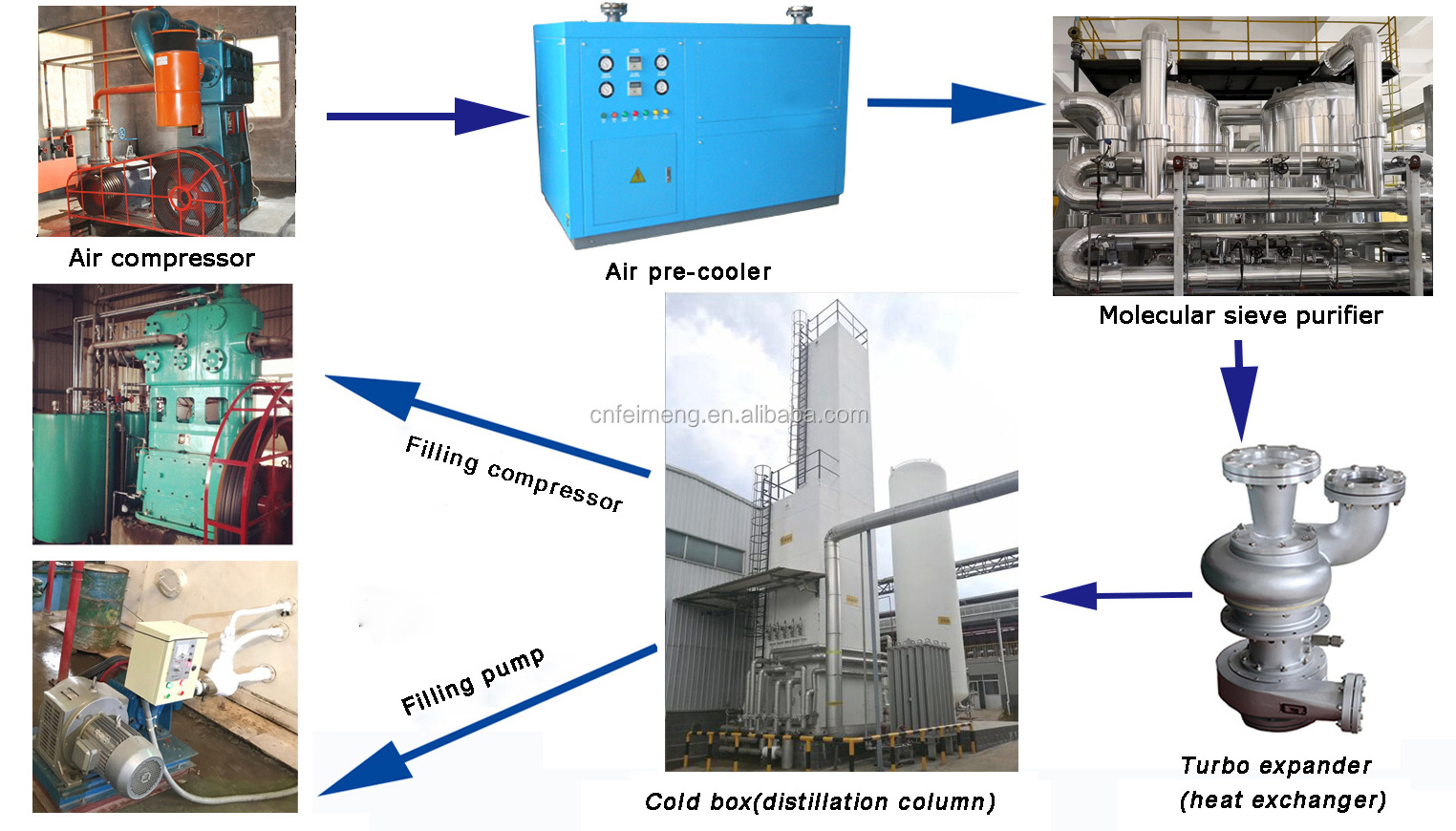

Fractional distillation column for industrial oxygen nitrogen plant

Air separation plant general steps:

- removal of mechnical impurities, such as dust and other impurities

- compression of air

- pre-cooling air

- air purifier(molecular sieve)

- heat excahnger or turbo expander

- distillation column

- filling and storage system

The feed air is divided into two streams after pre-processed: part air goes into gas bearing for being expanded, after which goes into upper column; the rest is continuously cooled in heat exchanger to saturation temperature with certain humidity-bearing, and then throttled to lower column.

Due to different boiling points of oxygen and nitrogen (oxygen is high than nitrogen), the nitrogen contained in the liquid air evaporates first, which goes up to the condensation side top of condenser evaporator through sieve trays, where it exchangers heat with liquid oxygen of the evaporation side, by which the gaseous nitrogen is liquefied to liquid nitrogen. Part liquid nitrogen is sent to the top of column through V-3 valve as the reflux liquid for the rectification of upper column after being subcooled by liquid nitrogen subcooler. After complete rectification in upper column, the required gaseous oxygen and nitrogen are respectively obtained from the bottom and top of upper column.

The waste nitrogen drawn from the upper position of upper column becomes the regeneration gas of purifier or blown off after being rewarmed in heat exchanger.

The oxygen out of fractionating column is rewarmed through subcooler and main heat exchanger, and then it is sucked into oxygen compressor to be compressor to 15 MPa to be charged into cylinder.

The nitrogen out of fractionating column is rewarmed through main heat exchanger, and then it is charged into cylinder or discharged.

1: Projects for foreign country:

KDONAr-1000/2000/32Y for Bangladesh

Cold box at seaport:

Kdon 350-800 in Bangladesh

2:Projects in domestic market:

Control room: