- Product Details

- {{item.text}}

Quick Details

-

Rated Voltage:

-

10KV

-

Tensile Strength:

-

8.0MPa

-

Fammability:

-

VW-1

-

Meets:

-

GB/T 1059-2007

-

Shrink ratio:

-

2.5:1

-

Min. shrink temp:

-

84degree

-

Min. full recovery temp:

-

120degree

-

Continuous operating temp:

-

-55---125degree

-

Usage:

-

Insulation protection

-

Sample:

-

Free

-

Delivery:

-

Fast Express with competitive price

-

Property:

-

Excellent physicochemical and electrical performence

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Volsun

-

Model Number:

-

450 volsun

-

Rated Voltage:

-

10KV

-

Tensile Strength:

-

8.0MPa

-

Fammability:

-

VW-1

-

Meets:

-

GB/T 1059-2007

-

Shrink ratio:

-

2.5:1

-

Min. shrink temp:

-

84degree

-

Min. full recovery temp:

-

120degree

-

Continuous operating temp:

-

-55---125degree

-

Usage:

-

Insulation protection

-

Sample:

-

Free

-

Delivery:

-

Fast Express with competitive price

-

Property:

-

Excellent physicochemical and electrical performence

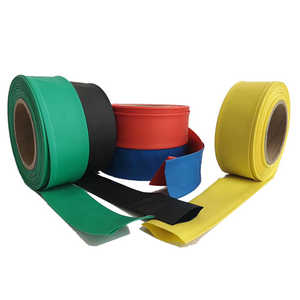

Heat Shrink high voltage polymer insulators Continuous Busbar Tubing

Description

Heat Shrink high voltage polymer insulators Continuous Busbar Tubing made of radiation cross-linked polyolefin, has excellent physicochemical and electrical performance. Typical applications include insulation of electrical bus bar with 10KV or lower voltage ratings, rectangular, square and round bus bars, inline bolted connections of rectangular bus bars, copper or aluminum bus bars, metal-clad switchgear, metal-enclosed bus bar, substation switchgear etc.

Features

Meets : GB/T 1059-2007

Shrink ratio : 2.5:1

Tracking resistant, low smoke emitting, flexible, flame retardant

Min. shrink temperature : ≥84 °C

Min. full recovery temperature : ≥120 °C

Continuous operating temperature : -55 °C~ 125 °C

RoHS compliant

Standard color : Red, yellow, green and other colors available on your request

Technical Data

|

Properties |

Typical Data |

|

|

Tensile strength |

≥8.0MPa |

ASTM D 2671 |

|

Elongation at break |

≥300% |

ASTM D 2671 |

|

Tensile strength after heat ageing |

≥6.9MPa |

130 °C ×168h |

|

Elongation after heat ageing |

≥100% |

130 °C ×168h |

|

Longitudinal change |

-8% ~ +8% |

ASTM D 2671 |

|

Oxygen index |

≥28 |

GB/T 2406 |

|

Heat shock |

No cracking |

supplement D |

|

Dielectric strength |

≥20kv/mm |

ASTM D 149 |

|

Shore A hardness |

≤90 |

GB 2411 |

|

Volume resistivity |

≥10 14 Ω.cm |

IEC 60093 |

Dimensions

|

Size |

Expanded inner diameter ( mm ) |

Recovered ( mm ) |

Standard package |

|

|

|

|

Inner diameter |

Wall thickness |

m/spool |

|

10kV 15/6 |

≥15 |

≤6.0 |

2.5±0.20 |

25 |