- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2023

-

Weight (KG):

-

2000 KG

-

Motor Power (kW):

-

7.5 kW

-

Product name:

-

Wire bending cutting machine

-

Speed:

-

0-20meters/minute

-

Wire diameter range:

-

2-14mm

-

Outside size:

-

2.0*1.2*1.5m

-

Crimping wheels material:

-

High quality metal alloy

-

Application:

-

Pre-crimped wire making for crimped wire mesh

-

CNC OR NC:

-

CNC

-

Main Motor:

-

7.5KW

-

Feature:

-

High precision,easy operation,reliable

-

Package:

-

Wooden case or pallet

Quick Details

-

Place of Origin:

-

Hebei

-

Brand Name:

-

APM

-

Marketing Type:

-

Hot Sales

-

Year:

-

2023

-

Weight (KG):

-

2000 KG

-

Motor Power (kW):

-

7.5 kW

-

Product name:

-

Wire bending cutting machine

-

Speed:

-

0-20meters/minute

-

Wire diameter range:

-

2-14mm

-

Outside size:

-

2.0*1.2*1.5m

-

Crimping wheels material:

-

High quality metal alloy

-

Application:

-

Pre-crimped wire making for crimped wire mesh

-

CNC OR NC:

-

CNC

-

Main Motor:

-

7.5KW

-

Feature:

-

High precision,easy operation,reliable

-

Package:

-

Wooden case or pallet

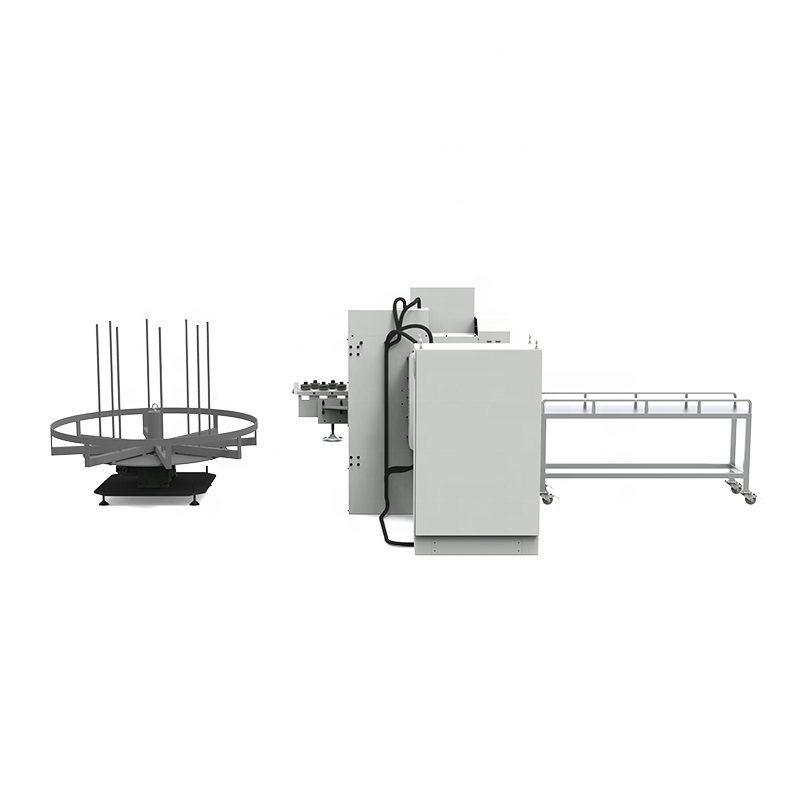

Automatic full CNC wave wire making steel bar bending cutting machine for crimped wire mesh

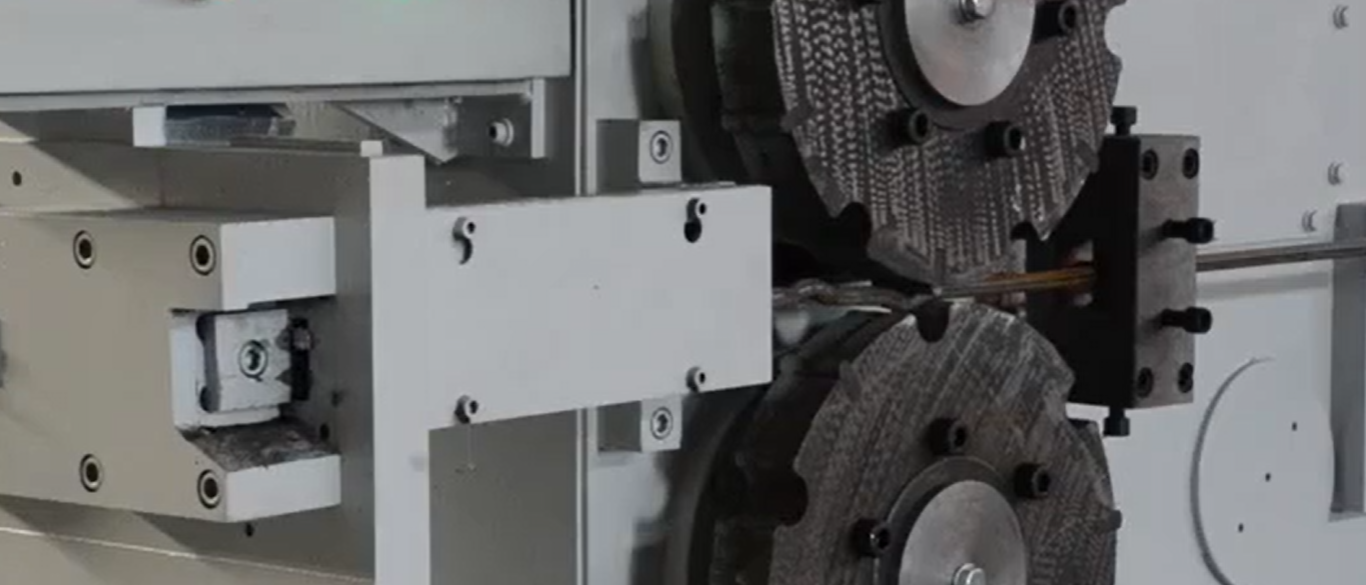

Advantage of wheels

1.Metial:12CrMnTi(alloy steel)

Feature:high hardness, abrasion.

2.Processing technology

Twice forging-- Feature:interior toughness

Wire cutting --Feature: make the surface smooth

So our wheel have a long service life.

We supply the crimped wheels with different wire diameter and opening size.

Technical Parmeters

| Type | APM-SK40 |

| Wire diameter | 2.0-14mm |

| Speed control | Reducer with frequency |

| Outside | 2.0*1.2*1.5m |

| Weight | 1500kg |

| Motor power | 7.5KWA 3.0KWA |

| Voltage | 50Hz 220V/380V 3Phase |

Sale service:

Maintenance period:

one year

We can send our technicist to the buyers' place to debug the machine and providing the training in 30 days after the machines arrive at the destination port.

The debugging fees:

free

The training fees:

First 7days is USD100/day for each technical,

The numbers of technical persons:

one technical person per machines at most.

The fees :

round-trip tickets, accommodation etc, are all in buyers' account.

During the maintenance period:

the parts damaged non-artificially will be provided free of charge. If buyers need the technicians, we will assign the technical staff to your company. And the fees ,such as round-trip tickets, accommodation etc, are all in buyers' account.

After the maintenance period:

If buyers need the machine parts, we will provide it as our cost. If buyers need the technicians, we will assign the technical staff to your company. And the fees ,such as round-trip tickets, accommodation etc, are all in buyers' account.