- Product Details

- {{item.text}}

Quick Details

-

Bore Size:

-

63/80/100/125/160/180/200mm

-

Power Stroke:

-

5 ~ 25mm

-

Output Pressure Force:

-

10~300KN

-

Stroke Speed:

-

10~400 mm/s

-

Working Pressure:

-

0.2-0.8MPa

-

Mounting Style:

-

Flange

-

Seals:

-

USA Herculesus

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CO-WIN

-

Product Name:

-

High speed power hydropenumatic 40 ton hydraulic cylinder

-

Bore Size:

-

63/80/100/125/160/180/200mm

-

Power Stroke:

-

5 ~ 25mm

-

Output Pressure Force:

-

10~300KN

-

Stroke Speed:

-

10~400 mm/s

-

Working Pressure:

-

0.2-0.8MPa

-

Mounting Style:

-

Flange

-

Seals:

-

USA Herculesus

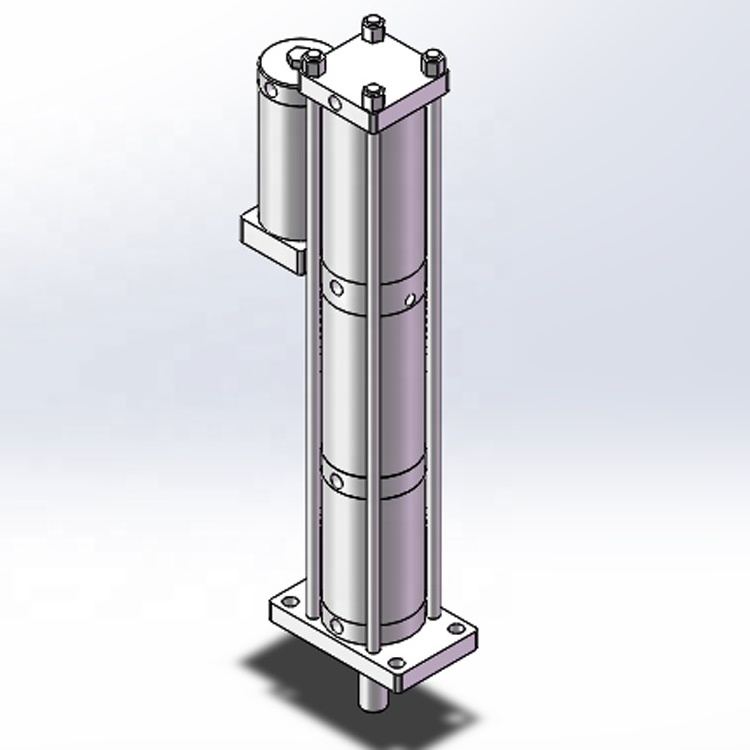

High speed power hydropenumatic 40 ton hydraulic cylinder

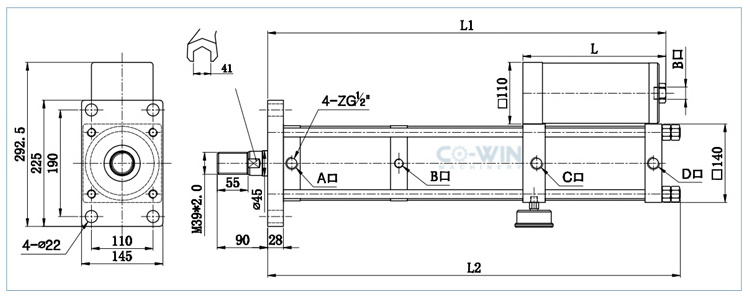

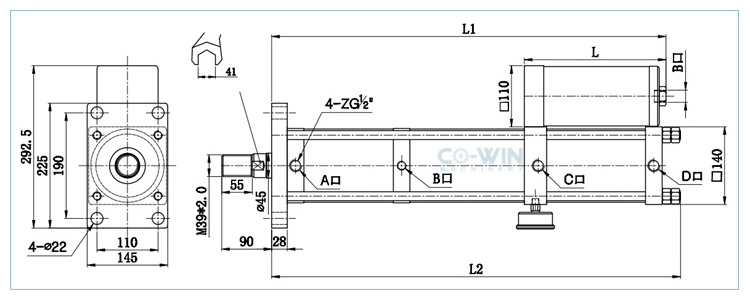

Overall Dimension Drawing

| PA-B-10T Fast Type Hydro Pneumatic Cylinder | ||||

| Total Stroke | Power Stroke | L | L1 | L2 |

| 50 | 5 | 215 | 575 | 572 |

| 100 | 5 | 235 | 695 | 672 |

| 150 | 5 | 255 | 815 | 772 |

| 200 | 5 | 285 | 945 | 872 |

| 50 | 10 | 215 | 575 | 636 |

| 100 | 10 | 235 | 695 | 736 |

| 150 | 10 | 255 | 815 | 836 |

| 200 | 10 | 285 | 945 | 936 |

| 50 | 15 | 215 | 575 | 700 |

| 100 | 15 | 235 | 695 | 800 |

| 150 | 15 | 255 | 815 | 900 |

| 200 | 15 | 285 | 945 | 1000 |

| 50 | 20 | 215 | 575 | 814 |

| 100 | 20 | 235 | 695 | 864 |

| 150 | 20 | 255 | 815 | 964 |

| 200 | 20 | 285 | 945 | 1064 |

Specification

| Action type | Double action |

| Action pressure | Clean compressed air of 3-7kg/cm² |

| Action-wear hydraulicoil | Anti-wear hydraulic oil of VG 68# |

| Operation temperature | 0-55℃ |

| Operating speed | 10-400mm/s |

| Anti-pressure of oil tank | 300kg/cm² |

| Anti-pressure of pneumatic cylinder | 12kg/cm² |

| Prepress stroke tolerance | +1.00mm 0.00mm |

| Power stroke tolerance | +0.20mm 0.00mm |

| Operation frequency | 10-50 times (related to the specific pre-pressure and booster stroke) |

| High pressure Boosting force | 1-80T(the actual output tonnage according to the customer demand) |

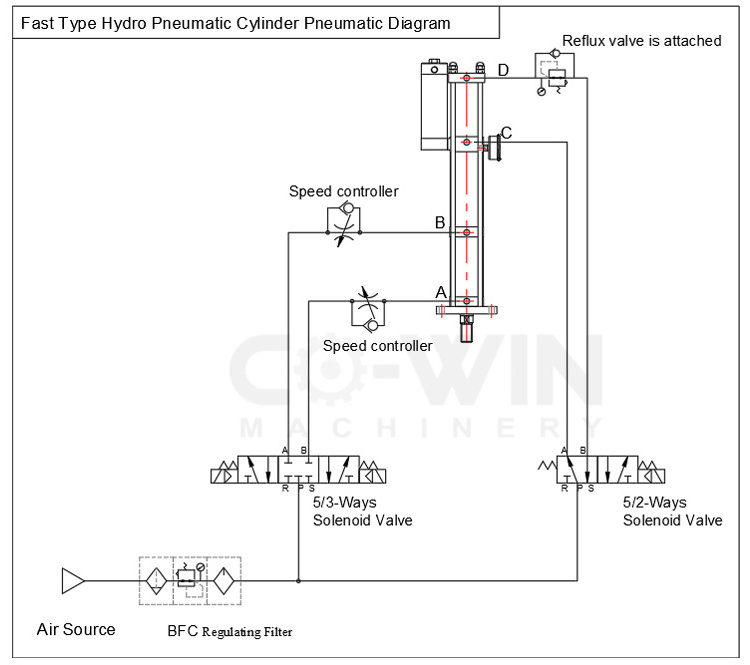

Working Principle

pneumatic cylinder is combined the oil pressure cylinder and booster together for taking pure gas press as the power source. It makes use of the different size of booster, the crosssection area compression ratio and Pascal energy conservation principle. Because of constant pressure, when the compression area change from small to large, the press would vary with the size, so as to raise the gas pressure to tens. Taking the prepress standard hydro pneumatic cylinder as an example: When the work gas pressed on the hydraulic oil (or working piston) surface, hydraulic oil would flow to the approach stroke cavity because of the air pressure, then the hydraulic oil would promote the workpiece to move rapidly. When the workpiece is meet the resistance larger than the gas pressure, it stops moving. At this point, the booster cavity start moving because of the signal (or pneumatic signal), then achieve the purpose of moding products!

Features:

- Fast speed: The action speed is faster than the hydraulic drive and it is more stability than pneumatic drive;

- High output: It can reach the highest output of oil hydraulic machine under same conditions, which can not be achieved by the pure pneumatic machine;

- Low price: The price is lower than the oil pressure system;

- Easy to maintain: The simple structure is easier to maintain than the oil pressure system;

- Low energy consumption: When continue to boost or stop moving, it does not need the motor to keep working as the hydraulic system, then the energy can be saved. And it is convenient to take the power source, so the actual energy consumption is equivalent to 10%-30% of hydraulic power system;

- No leakage: Energy conversion is easy with zero leakage, so not worry about the environmental pollution;

- No harm to the die: In order to meet the technology needs, stamping pressure and the work stroke can keep within the provided area without adjustable levels;

- Soft landing: Soft-stamping technology reduce the noise to protect the die;

- Fault less: No temperature rising problems unlike the hydraulic system;

- Small space: Space area can be less than 50% compare with normal air cylinder and hydraulic station;