- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

custom

-

Weight (T):

-

0.05 T

-

Power (kW):

-

15-80

-

Usage:

-

High Temperature Heating Treatment

-

Max temperature:

-

1900 degree

-

Temperature control:

-

PID Automatic Control

-

Vacuum limit:

-

6.7*10 -3Pa

-

Heating element:

-

Copper induction coil.

-

Furnace structure:

-

Double Shell

-

VAcuum system:

-

Leybold pump

-

Product name:

-

vacuum melting furnace

-

After Sale Service:

-

Online Support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Marketing Type:

-

2022 new vacuum melting furnace

-

Brand Name:

-

Cdocast

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

custom

-

Weight (T):

-

0.05 T

-

Power (kW):

-

15-80

-

Usage:

-

High Temperature Heating Treatment

-

Max temperature:

-

1900 degree

-

Temperature control:

-

PID Automatic Control

-

Vacuum limit:

-

6.7*10 -3Pa

-

Heating element:

-

Copper induction coil.

-

Furnace structure:

-

Double Shell

-

VAcuum system:

-

Leybold pump

-

Product name:

-

vacuum melting furnace

-

After Sale Service:

-

Online Support

Product Overview

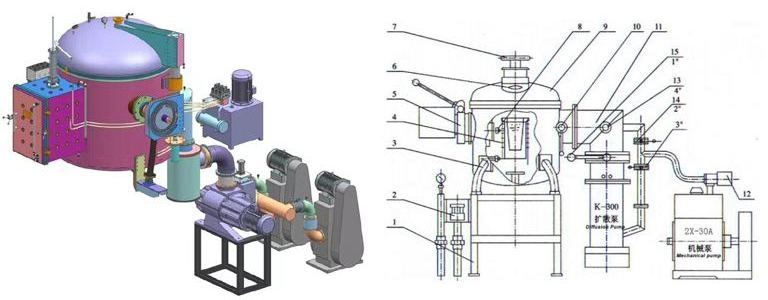

1,Support frame; 2, cooling system; 3, Furnace body; 4, Inductor; 5, Seal Sewing Bearing; 6, Inspecion window; 7, Feeder; 8,Electrode ; 9, Furnace Cover;10, Temperature measuring device; 11, Vacuum system; 12, Electromagnetism Vacuum inflation valve; 13,deflation valve;14, Dia 50 vacuum valve, 15, diameter 300

Feature

1. Small vacuum melting furnace has fashionable appearance and compact structure, covering an area of less than 2 square meters

2. The vacuum furnace can be designed as a side door opening structure, which is convenient for taking and placing materials.

4. The furnace shell adopts double-layer water cooling structure, and the surface temperature does not exceed 40 ℃, which is more safe and reliable.

5. An observation window is arranged on the furnace cover to facilitate the observation of material melting. Gas inlet and outlet are installed on the furnace body, and multiple KF interfaces are reserved to facilitate connection to other devices.

6. The electrode can rotate.

7. Equipped with a secondary feeding device, other elements can be added in the smelting process to make various alloy materials.

8. IGBT special power supply and all digital circuit are adopted. The electrical system is equipped with overcurrent, overvoltage feedback and protection circuit. The electric control panel box is made according to Siemens standard, with high temperature control accuracy and convenient operation.

9. Small vacuum melting furnace can adopt two-stage pump, that is, mechanical pump and molecular pump, and the vacuum degree can reach 8 × 10-4P.

2. The vacuum furnace can be designed as a side door opening structure, which is convenient for taking and placing materials.

4. The furnace shell adopts double-layer water cooling structure, and the surface temperature does not exceed 40 ℃, which is more safe and reliable.

5. An observation window is arranged on the furnace cover to facilitate the observation of material melting. Gas inlet and outlet are installed on the furnace body, and multiple KF interfaces are reserved to facilitate connection to other devices.

6. The electrode can rotate.

7. Equipped with a secondary feeding device, other elements can be added in the smelting process to make various alloy materials.

8. IGBT special power supply and all digital circuit are adopted. The electrical system is equipped with overcurrent, overvoltage feedback and protection circuit. The electric control panel box is made according to Siemens standard, with high temperature control accuracy and convenient operation.

9. Small vacuum melting furnace can adopt two-stage pump, that is, mechanical pump and molecular pump, and the vacuum degree can reach 8 × 10-4P.

PRODUCT SPECIFICATIONS

|

Model number

|

VIF-1

|

VIF-2

|

VIF-3

|

VIF-5

|

VIF-10

|

VIF-25

|

|||||

|

Max melting weight (calculated by molten iron)

|

1KG

|

2KG

|

3KG

|

5KG

|

10KG

|

25KG

|

|||||

|

Max heating temperature ℃

|

1900℃

|

1900℃

|

1700℃

|

1700℃

|

1700℃

|

1700℃

|

|||||

|

Power supply

|

HF induction power supply

|

|

|

IF induction power supply

|

|

|

|||||

|

Oscillation frequency

|

30-80KHZ

|

30-80KHZ

|

30-80KHZ

|

1-20KHZ

|

1-20KHZ

|

1-20KHZ

|

|||||

|

Maximum input power

|

15KW

|

15KW

|

35KW

|

45KW

|

60KW (can be changed according to material)

|

80KW (can be changed according to material)

|

|||||

|

Heating current

|

2-50A

|

2-52A

|

12-70A

|

15-95A

|

10~90A

|

20~130A

|

|||||

|

Cooling water requirements

|

≥0.2MPa ≥6L/min

|

|

|

|

10P (Change according to different requirements)

|

|

|||||

|

Power supply weight

|

35KG

|

35KG

|

68KG

|

45KG

|

70KG

|

80KG

|

|||||

|

Input voltage

|

3P 380V 50/60HZ

|

|

|

|

|

|

|||||

Packing & Delivery

Customer Photos

FAQ

1. What is your advantage to compared to others?

① We provided turnkey solution, cost-effective, highly efficient, durable and easy-to operate machine is what we deliver.

② We have strict quality control system, before being dispatched from our factory all of our equipment will undergo a series of

strict test, including the appearance quality test, voltage electrical test, aging test also the package strength checking.

2. If our machine meets fault, how could you help us to solve it?

For failures caused by using process, we will send our aftersales engineer to discuss with you, and you should provide the video

how the machine is broken,we will find out which part of the machine is broken and then we will send you the broken part By DHL.

3. What is your warranty?

Our warranty period comes from the machine begin to run normally and we will provide the whole life technology support to you for

free.

All products sold by COOLDO In warranty period,we will provide you the spare parts for free. Our engineer will help you do the

aftersales through our remote control system.When out of one year warranty time, we will provide the spare parts with the cost

price for the whole machine lifetime.

① We provided turnkey solution, cost-effective, highly efficient, durable and easy-to operate machine is what we deliver.

② We have strict quality control system, before being dispatched from our factory all of our equipment will undergo a series of

strict test, including the appearance quality test, voltage electrical test, aging test also the package strength checking.

2. If our machine meets fault, how could you help us to solve it?

For failures caused by using process, we will send our aftersales engineer to discuss with you, and you should provide the video

how the machine is broken,we will find out which part of the machine is broken and then we will send you the broken part By DHL.

3. What is your warranty?

Our warranty period comes from the machine begin to run normally and we will provide the whole life technology support to you for

free.

All products sold by COOLDO In warranty period,we will provide you the spare parts for free. Our engineer will help you do the

aftersales through our remote control system.When out of one year warranty time, we will provide the spare parts with the cost

price for the whole machine lifetime.

Hot Searches