·

Back gauge positioning control.

·

Intelligent positioning function.

·

One-way and two-way positioning function, effectivelyeliminate screw clearance.

·

Concession and escape function.

·

Automatic search for reference point function.

·

One-key backup and restore function of parameters.

·

Quick position teaching function.

·

40multi-step program storage spaces, each program has 25 steps.

·

Power-off protection function.

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

4000 mm

-

Backgauge Travel (mm):

-

200 - 800 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

NOKA

-

Power (kW):

-

10 kW

-

Weight (KG):

-

4500 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3860*1700*1700mm

-

Year:

-

2021

-

Warranty:

-

3 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control system:

-

E21s NC

-

Cutting thickness:

-

10mm(Carbon steel)

-

Cutting Lenght::

-

3200mm

-

Back Gauge:

-

20-750mm

-

Quality standard::

-

German standard

-

Main Motor:

-

Siemens from Germany

-

Tubing connector::

-

EMB form Germany Brand

-

Hydraulic System::

-

Bosch-Rexroth form Germany

-

BackGauge Drive::

-

Inverter from Taiwan delta

-

Certification:

-

ISO 9001

Quick Details

-

Max. Cutting Width (mm):

-

6000

-

Max. Cutting Thickness (mm):

-

20 mm

-

Shearing Angle:

-

1

-

Blade Length (mm):

-

4000 mm

-

Backgauge Travel (mm):

-

200 - 800 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

NOKA

-

Power (kW):

-

10 kW

-

Weight (KG):

-

4500 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3860*1700*1700mm

-

Year:

-

2021

-

Warranty:

-

3 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control system:

-

E21s NC

-

Cutting thickness:

-

10mm(Carbon steel)

-

Cutting Lenght::

-

3200mm

-

Back Gauge:

-

20-750mm

-

Quality standard::

-

German standard

-

Main Motor:

-

Siemens from Germany

-

Tubing connector::

-

EMB form Germany Brand

-

Hydraulic System::

-

Bosch-Rexroth form Germany

-

BackGauge Drive::

-

Inverter from Taiwan delta

-

Certification:

-

ISO 9001

Product Description

It is a machine that uses one blade to make a reciprocating linear motion to cut the plate relative to the other blade. By moving the upper blade and the fixed lower blade, a reasonable blade gap is used to apply shearing force to metal plates of various thicknesses to break and separate the plates according to the required size. Shearing machine is one of the forging machinery, its main function is the metal processing industry. Products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automotive, electric power, electrical appliances, decoration and other industries to provide special machinery and complete equipment.

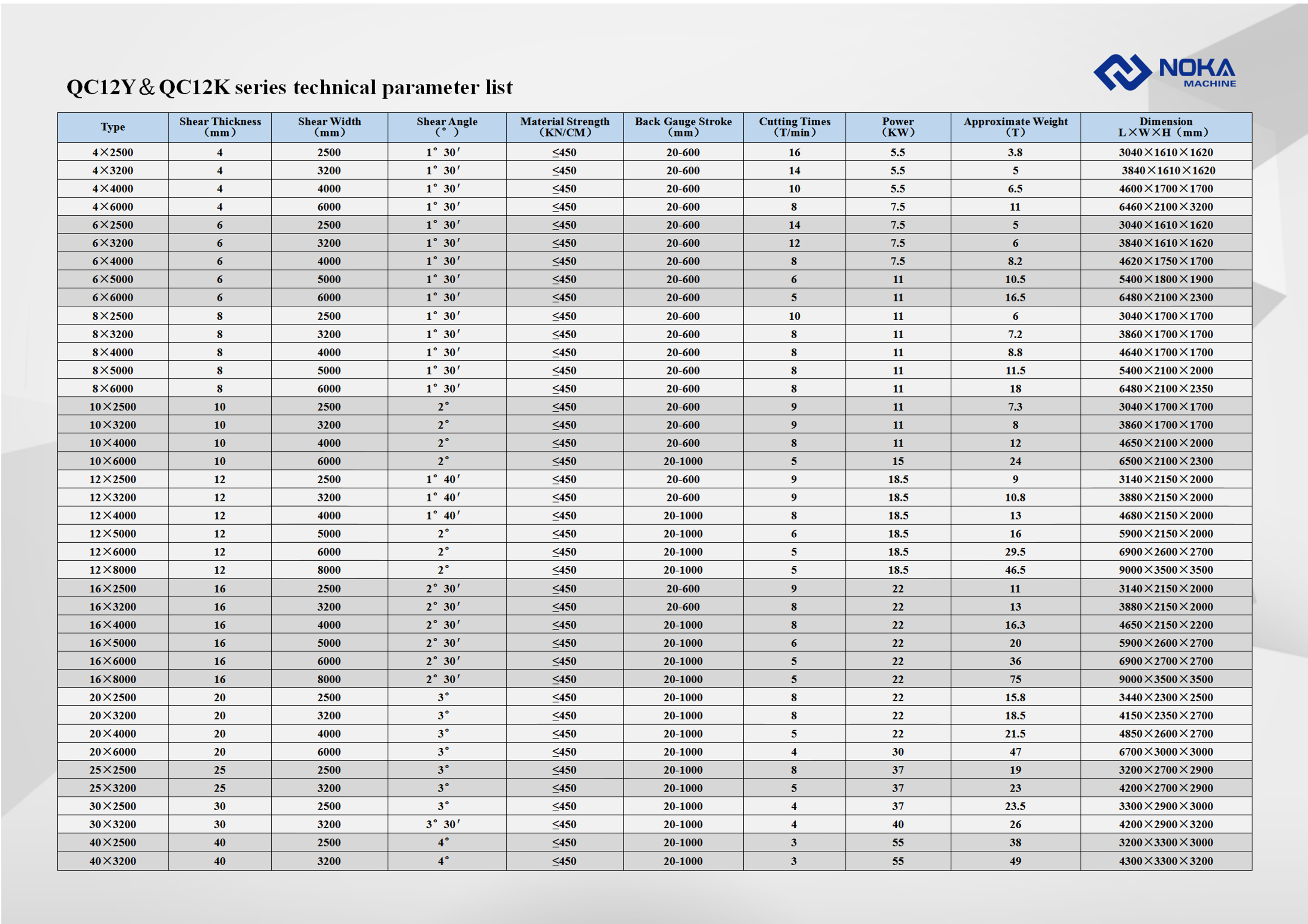

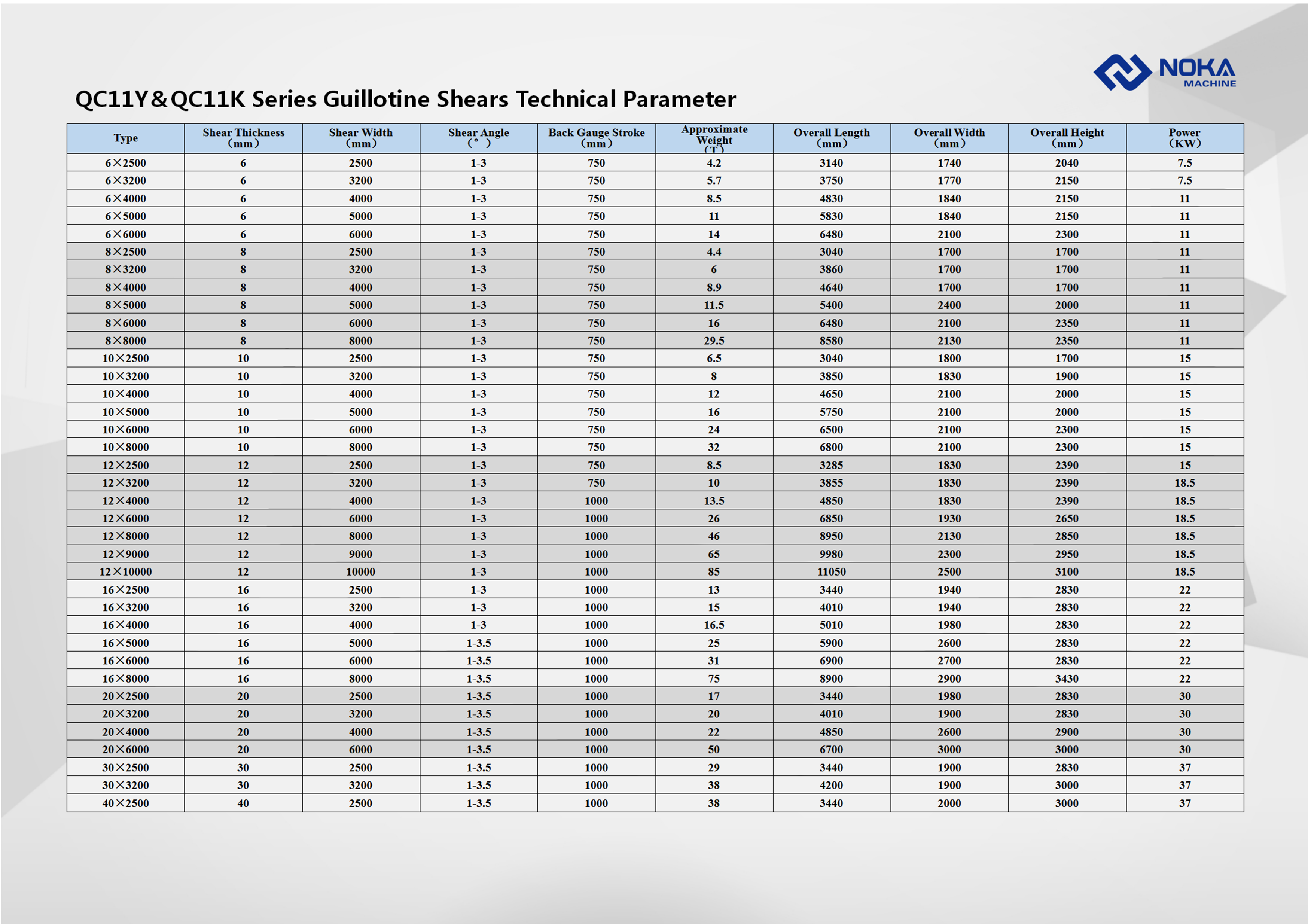

More Models, Please Refer To The Technical Data Sheet

-

E21S operating system function introduction:

Detailed Images

Electrical Cabinet

The Distribution Box Has A Scientific Design And A Heat Sink. With Ground Protection. Standard Schneider Electric And Omron Power Switch Safe And Efficient

Metal Fence

The Machine Is Equipped With Metal Guardrails As Standard, Which Is Safe And Beautiful. It Guarantees The Quality Of The Machine And Gives The Worker The Protection As Much As Possible.

Electrical system

Electrical Cabinet under the standard of IP65, Electrical under international CE Standard, safe and reliable, strong anti

interference capability.Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal

switch,easy to operate.Front Side Covers with safety switches, Back light safety guards,Foot pedal conforming to CE regulation.

interference capability.Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal

switch,easy to operate.Front Side Covers with safety switches, Back light safety guards,Foot pedal conforming to CE regulation.

Blade Adjust and Cutting Precision

Shearing angle is Variable, which can reduce the shearing deformation of sheet metal and can shear much thicker sheet metal.

Function of shearing in sections, function of aligning with light.Upper blade holder has inward tiling structure to facilitate

material feed in and also enhance accuracy of the work piece.

Rectangular blades with four cutting edges to prolong working life, adjustable shearing angle to reduce deformation of the sheet.

Function of shearing in sections, function of aligning with light.Upper blade holder has inward tiling structure to facilitate

material feed in and also enhance accuracy of the work piece.

Rectangular blades with four cutting edges to prolong working life, adjustable shearing angle to reduce deformation of the sheet.

Main Motor From Siemens

Siemens motors ensure continuous and long-term reliable operation of key components. The heat dissipation ribs are horizontally and vertically distributed: all motors are designed with IP55 protection and are customized according to Siemens requirements. Excellent rotor processing technology, high surface blasting finish

Hydraulic Oil Pump from SUNNY

1. The ability to achieve high working pressure in a compact form factor ensures high power-to-weight ratio and reduced installation costs.

2. The inherent low noise characteristics of the daughter blade mechanism improve operator comfort.

3.12 The blade system ensures that the amplitude of the flow pulsation is small and the system noise characteristics are low.

Hydraulic Valve From RexRoth

Rexroth oil pump has slotted control swashplate design, continuously variable displacement, good self-priming, allowing continuous working pressure of 350 bar, low noise, long service life, drive shaft can absorb axial and radial loads, modular Design, through-axis drive control time is short, pump position is optional, installation position can also be selected, can work with HFC liquid under reduced operating parameters.

NOK Seal

NOK seals are used in the reciprocating motion of hydraulic, air pressure and hydraulic machines. The seal made of NOK material surpasses the performance of the previous products. The sealing product series developed on the basis of this material greatly improves the sealing reliability of industrial machines.

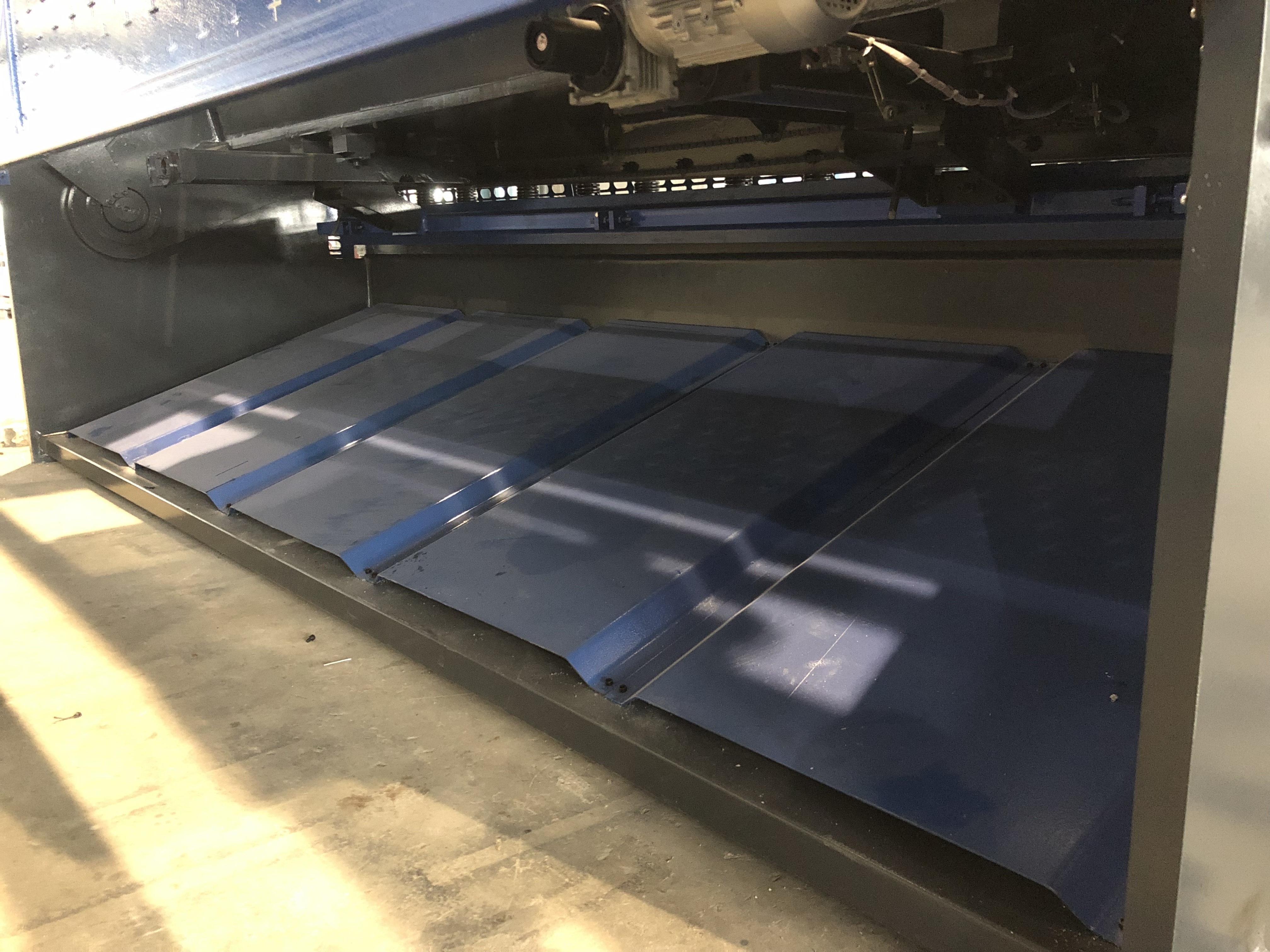

Back Gauge / Automatic Blanking System

With higher precision, to ensure the positioning precision. It brings the higher accuracy of processing.

In the production process of the shearing machine, the finished product of the shearing plate is freely slid onto the tray through the slope of the blanking slide to achieve the purpose of dividing and blanking.

Clamp and blade

High quality stop in, to ensure the sheet metal to be press well when do shering. Sharp blade to make the machine shearing fast

and with high precision

and with high precision

Related Products

Packing&Shipping

Before the machine is shipped, the mould will be coated with antirust oil. Special and effective packing. The machine is

transported by standard container, and the common ones are 40 OT / 20 OT / 40 HQ / 40 GP / 20 GP. Inside the container, there will

be more wire rope and multiple angle fixing machines.

We will also make videos to let you know how the equipment is loaded into the container.

Please contact our sales consultant for the best shipping plan and accurate quotation

transported by standard container, and the common ones are 40 OT / 20 OT / 40 HQ / 40 GP / 20 GP. Inside the container, there will

be more wire rope and multiple angle fixing machines.

We will also make videos to let you know how the equipment is loaded into the container.

Please contact our sales consultant for the best shipping plan and accurate quotation

After Sales Service

After-sale Protection

1--Provide detailed operation and installation files and videos with the machine.

2--Free training for customers in the factory.

3--Engineers and sales consultants 24 hours online video with you, troubleshooting machine.

4-- Replace the problem accessories for you free of charge during the warranty period.

5-- The dealer goes to repair .

6-- The engineer goes to serve.

Company Introduction

Anhui NOKA Machinery

Manufacturing Co., Ltd.

was established in 1994, located in the ancient capital of Nanjing, the steel city Maanshan junction point to see a lot of industrial parks.

The company specializes in CNC machine tools, forging machinery, mechanical blade molds, mechanical parts, mechanical presses,

hydraulic presses, hydraulic presses, ironwork, mechanical bending and so on.

Here, NOKA has a long and strong engineering experience, and hopes to become a quality-oriented professional machinery

manufacturing company that serves the industry.

The company specializes in CNC machine tools, forging machinery, mechanical blade molds, mechanical parts, mechanical presses,

hydraulic presses, hydraulic presses, ironwork, mechanical bending and so on.

Here, NOKA has a long and strong engineering experience, and hopes to become a quality-oriented professional machinery

manufacturing company that serves the industry.

Customer Photos

Recommend Products

Hot Searches