- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

50/60HZ,380V/220V

-

Power:

-

5KW

-

Dimension(L*W*H):

-

2270*1400*1970mm

-

Weight:

-

1500 kg

-

Marketing Type:

-

New Product 2022

-

Paper Cup Size:

-

2~16OZ

-

Raw material:

-

One or Two side PE coated Paper

-

Suitable paper weight:

-

140-350gsm

-

Power Source:

-

50/60HZ,380V/220V(better use 380V,3 Phase)or special Power requirement

-

Total Power:

-

5KW

-

Total Weight:

-

GW/NW:180KGS/1750KGS

-

Pack Size(L*W*H):

-

2270*1400*1970mm(machine size) 1000*750*2100mm(collecting table size)

-

Cup Side Welding:

-

Ultrasonic heater

-

Cup Bottom Knurling:

-

Heater Knurling(if use single PE coated paper)

Quick Details

-

Production Capacity:

-

95-105pcs/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mingyuan

-

Voltage:

-

50/60HZ,380V/220V

-

Power:

-

5KW

-

Dimension(L*W*H):

-

2270*1400*1970mm

-

Weight:

-

1500 kg

-

Marketing Type:

-

New Product 2022

-

Paper Cup Size:

-

2~16OZ

-

Raw material:

-

One or Two side PE coated Paper

-

Suitable paper weight:

-

140-350gsm

-

Power Source:

-

50/60HZ,380V/220V(better use 380V,3 Phase)or special Power requirement

-

Total Power:

-

5KW

-

Total Weight:

-

GW/NW:180KGS/1750KGS

-

Pack Size(L*W*H):

-

2270*1400*1970mm(machine size) 1000*750*2100mm(collecting table size)

-

Cup Side Welding:

-

Ultrasonic heater

-

Cup Bottom Knurling:

-

Heater Knurling(if use single PE coated paper)

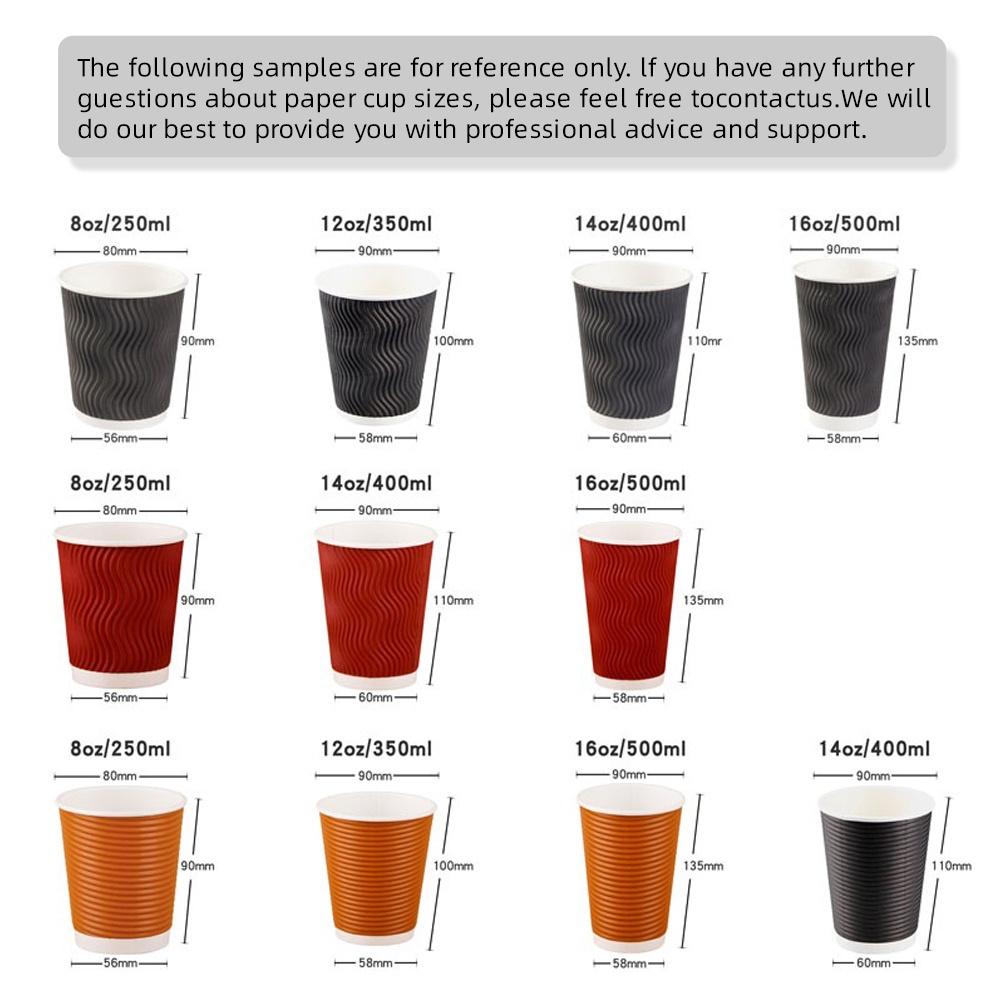

Paper cup size

The following samples are for reference only. If you have any further questions about paper cup sizes, please feel free to

contactus. We will do our best to provide you with professional advice and support.

contactus. We will do our best to provide you with professional advice and support.

1.High-speed production capacity:

It can produce 100-110 cups per minute

, improving production efficiency.

2.Multiple size applicability:

Suitable for producing cups ranging from 2 to 16 ounces

, meeting various size requirements.

3.

Equipped with 10 molds and 4 bottom

heaters, ensuring better bottom sealing and preventing leakage issues.

4.Precise and stable operation:

Adopting an open cam and full gear driving system to ensure precise and stable machine operation, delivering reliable production results

.

5.Wide applicability: Suitable for producing various types of paper cups, including hot drinks, cold drinks, coffee, tea, and ice cream cups.

6、Automatic lubrication system:

The automatic lubrication system ensures the smooth operation of all mechanical

components and extends the machine's lifespan.

components and extends the machine's lifespan.

The above are the features of the JBZ-0C100 paper cup forming machine.

Its high-speed production capacity, versatility in handling multiple cup sizes, precise and stable operation, and excellent bottom sealing make it an ideal choice for paper cup production.

|

Model

|

High Speed Intelligence Model Ultrasonic Paper Cup Machine JBZ-OC100

|

|

|

|

||||

|

Cup Side Welding

|

Ultrasonic heater

|

|

|

|

||||

|

Paper Cup Size

|

2~16 0Z (Mould exchangeable, Max Cup Height:115mm , Max Bottom width :76mm

|

|

|

|

||||

|

Rated Speed

|

95-105pcs/min ( Speed affected by cup size, paper quality & thickness)90Z,280GSM paper cup Stable running speed 100 pcs eachmin

|

|

|

|

||||

|

Raw Material

|

One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

|

|

|

|

||||

|

Suitable paper weight

|

140-350gsm

|

|

|

|

||||

|

Power Source:

|

50/60HZ,380V/220V ( better use 380V,3 Phase ) or special Powerrequirement.

|

|

|

|

||||

|

Total Power

|

5KW

|

|

|

|

||||

|

TotalWeight

|

GW/NW:1800KGS/1750KGS

|

|

|

|

||||

|

Pack Size(L*W*H)

|

2450*1360*1980mm(machinesize)960*700*2200mm(collecting table size)

|

|

|

|

||||

|

Working AirSource

|

Air pressure:0.4Mpa

Air Out-put:0.6m3/minute

|

|

|

|

||||

|

Cup SideWelding

|

Heater Knurling

|

|

|

|

||||

|

Cup BottomHeating

|

1side PE paper by heater knurling;2side PE paper by cool device (circle water) knurling.

|

|

|

|

||||

|

Cup BottomKnurling

|

Heater Knurling (if use single PE coated paper)

|

|

|

|

||||

|

OEM ( Show Client Company Name in Machine Panel ) is welcome in our factory

|

|

|

|

|

||||

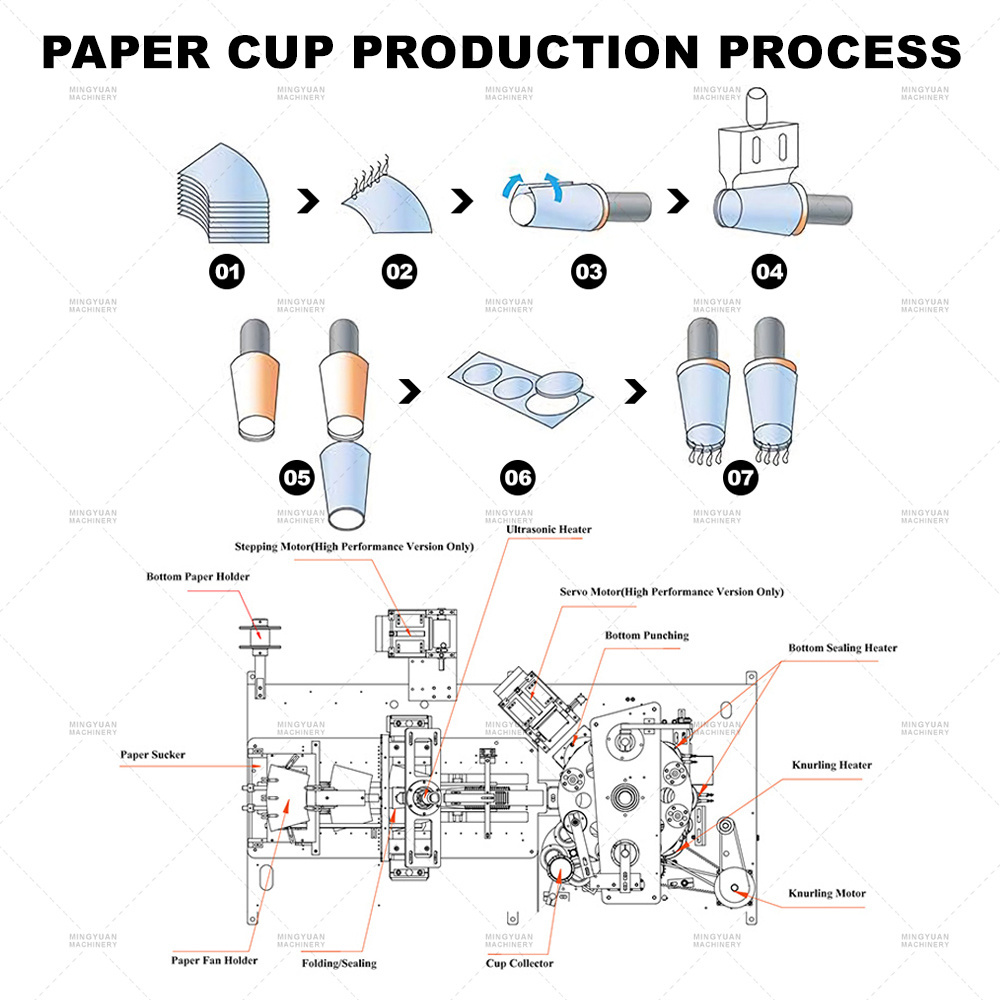

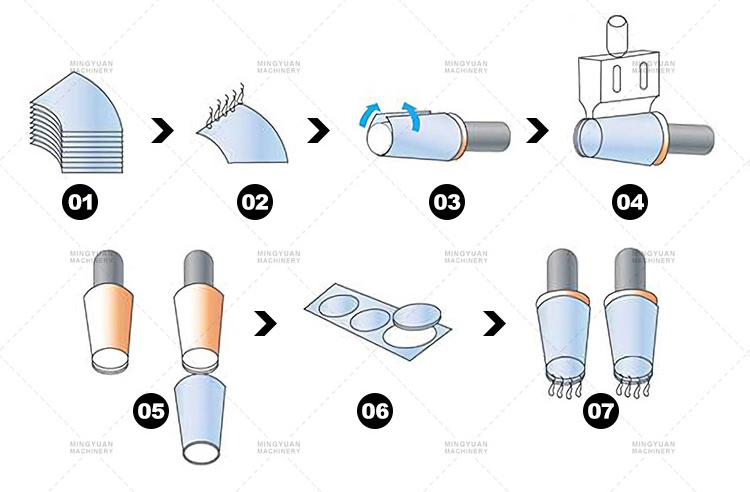

Paper cup production process

1. paper fan in rack, 2.paper fan feeding, 3.paper fan hugging, 4.paper fan sealing, 5. paper cup feeding to mould,

6. bottom paper punching, 7. bottom paper sealing

PRODUCT FLOOR PLAN

product details

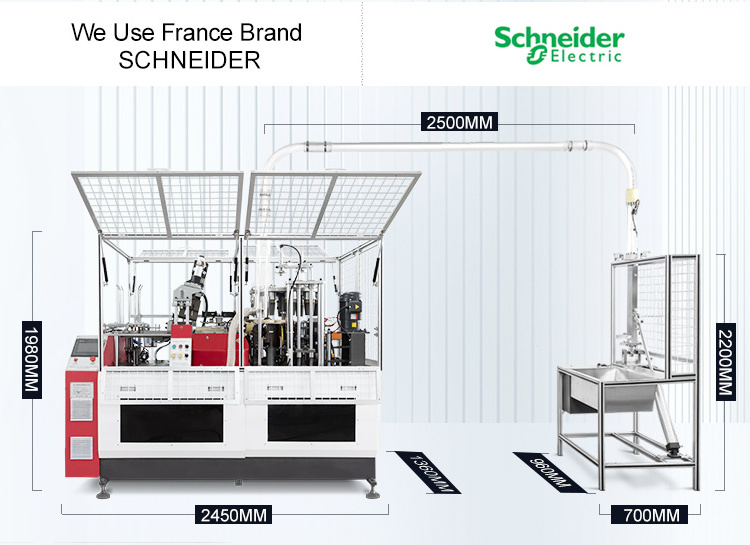

Electric System

Our machine is equipped with renowned components, including Schneider

AC contactor

and

Delta PLC controller

, to ensure the reliability and excellent performance of the machine.

Machine accessories

Safety Cover:

Protection during the operation of the machine

Cup Collection Rack:

Stable stacking and orderly arrangement of paper cups.

Selling Point of a Product

TEN MOULDS

Newly designed with ten molds for faster and more stable operation.

FOUR BOTTOM HEATER SYSTEM

ensuring better bottom sealing and preventing leakage issues.

FREE TOOLS,REPLACEABLE PARTS

we supply more replaceable parts to client to replace the brokenspare parts and help client save money and time to buy it

Company strength

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product

machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is

feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Hot Searches