- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

250 mm

-

Width of Working Table (mm):

-

800 mm

-

Place of Origin:

-

Jiangsu, China

-

Weight (KG):

-

4500

-

Motor Power (kw):

-

5.5 kw

-

Name:

-

CNC Press Brake

-

Raw Material:

-

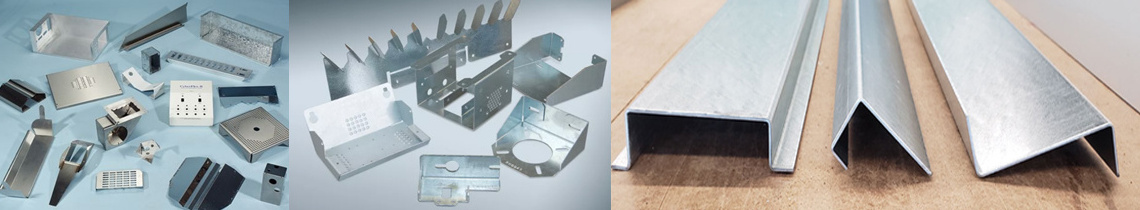

steel stainless sheet

-

Color:

-

orange and white hydraulic press brake

-

stop back:

-

Manual Opertation

-

motor:

-

servo motor

-

CNC or not:

-

CNC press brake

-

control system:

-

optional E21,E210, DA41,MD320

-

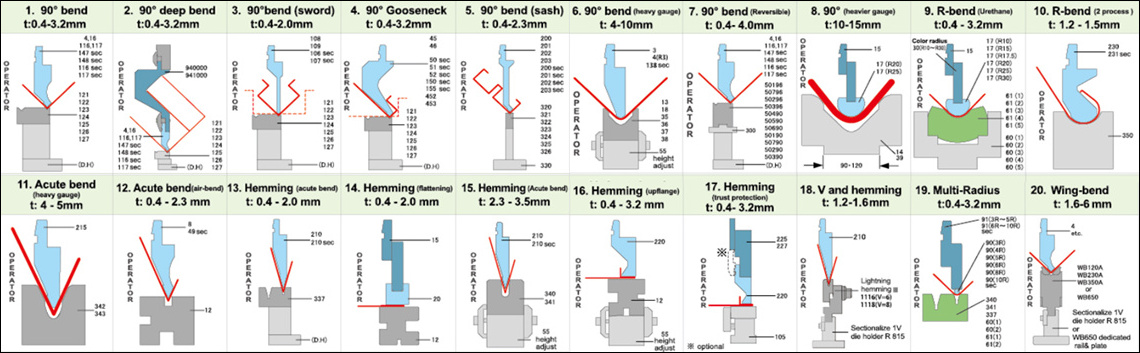

Dies:

-

Customize

-

Sealing rings:

-

Volqua Japan

-

Application:

-

Metal steel sheet bending

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

2500 mm

-

Slider Stroke (mm):

-

120 mm

-

Throat Depth (mm):

-

250 mm

-

Width of Working Table (mm):

-

800 mm

-

Place of Origin:

-

Jiangsu, China

-

Weight (KG):

-

4500

-

Motor Power (kw):

-

5.5 kw

-

Name:

-

CNC Press Brake

-

Raw Material:

-

steel stainless sheet

-

Color:

-

orange and white hydraulic press brake

-

stop back:

-

Manual Opertation

-

motor:

-

servo motor

-

CNC or not:

-

CNC press brake

-

control system:

-

optional E21,E210, DA41,MD320

-

Dies:

-

Customize

-

Sealing rings:

-

Volqua Japan

-

Application:

-

Metal steel sheet bending

NC Torsion Bar Horizontal Bending Press Brake Machine Manufacturer For Sale Craigslist for Door Frame With 2500mm

Performance characteristics

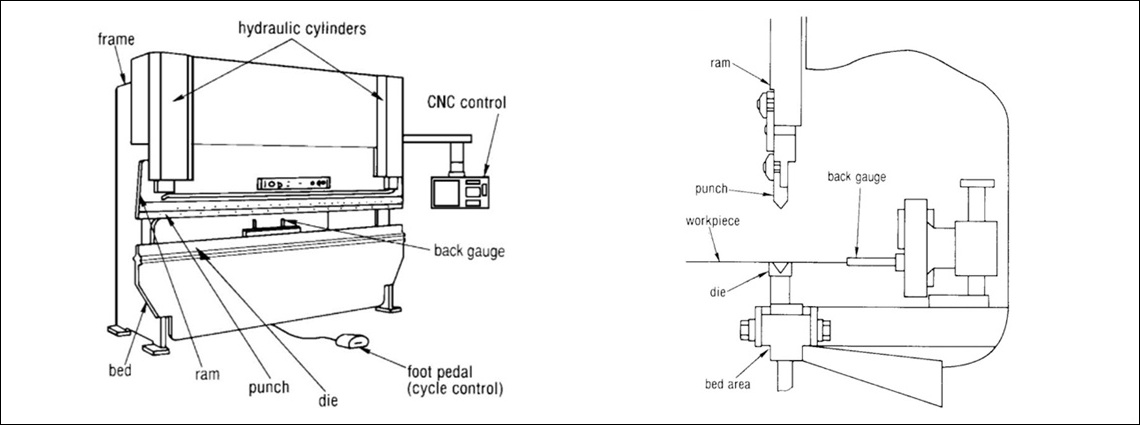

# Integral welding processing structure

# International famous brand electro-hydraulic servo valve and grating ruler form closed loop control mode

# High slider position feedback accuracy, accurate and smooth operation, good synchronization performance, bending accuracy, high slider repeat positioning accuracy.

# Rear baffle material can be according to customer demand to adopt more complete function of the rear baffle material shaft of the rear baffle material mechanism.

# The hydraulic system adopts integrated control system, which reduces the installation of pipelines, eliminates oil leakage, ensures the working stability of machine tools, and makes the appearance scientific and beautiful.

# Hydraulic deflection automatic compensation mechanism, eliminate the impact of slider deformation on the quality of the workpiece, CNC system automatically adjust the amount of compensation, easy and accurate operation.

# CNC system using the Netherlands DELEM, Italy ESA, Switzerland CYBELEC and other well-known brands dedicated CNC bending machine system.

Standard configuration specification:

# Hydraulic system: BOSCH, Germany

# Servo motor and drive: nanjing easton

# Grating ruler: HEIDENHAIN, Germany, GIVI, Italy

# Ball screw and linear guide: HIWIN, Taiwan

# Main electrical components: French SCHNEIDER

# Bench compensation: hydraulic compensation or mechanical compensation

# Simple adjustable pre-moving bracket with guide rail

Working principle of hydraulic deflection compensation mechanism

In the process of bending, the Angle of the bending workpiece is inconsistent due to the certain amount of deformation between the slider and the workpiece, especially the hot-rolled plate of stainless steel, which has large rebound force and large error.This series bending machine adopts the workbench hydraulic automatic deflection compensation mechanism, it is composed of a set of oil cylinder installed in the workbench, and each compensation location of the oil cylinder, size is according to the slider, finite element analysis of the deflection curve design compensation table, hydraulic compensation is after the former three vertical plate, the relative displacement between the neutral version of the convex compensation, to achieve its principle is accomplished by elastic deformation of steel itself raised, so the amount of compensation can be realized within the elastic range in the workbench.

Sample show

Accessories brand list

OPITING PART

Upper Die And Down Tool

Controller

Back Gauge Of Press Brake

Hydraulic Up Clamping System Express Down Clamping System

Wireless Foot Pedal Sheet Supports Systems

Laser line For Bending Without Back gauge

Front Sheet lifters——CNC Front Support ——Lengthened Front Support

Technical parameter

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.