- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

100L

-

Weight (KG):

-

700 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jinfeng

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

90*60*160CM

-

Power (kW):

-

3 kW

-

Product name:

-

Vacuum Emulsifying Mixer Liquid Soap Making Machine

-

Motor:

-

SIMENS

-

Stirrer type:

-

High Speed Homogenizer

-

Control:

-

PLC+ Touch Screen

-

Usage:

-

Chemical.Cosmetic

-

Speed System:

-

Frequency

-

Heating method:

-

Steam/Electricity

-

Capacity:

-

Alternative

-

Packing:

-

Wooden Case

Quick Details

-

Barrel Volume (L):

-

150

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

1 - 60 r.p.m

-

Max. Loading Capacity:

-

100L

-

Weight (KG):

-

700 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jinfeng

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

90*60*160CM

-

Power (kW):

-

3 kW

-

Product name:

-

Vacuum Emulsifying Mixer Liquid Soap Making Machine

-

Motor:

-

SIMENS

-

Stirrer type:

-

High Speed Homogenizer

-

Control:

-

PLC+ Touch Screen

-

Usage:

-

Chemical.Cosmetic

-

Speed System:

-

Frequency

-

Heating method:

-

Steam/Electricity

-

Capacity:

-

Alternative

-

Packing:

-

Wooden Case

Product Description

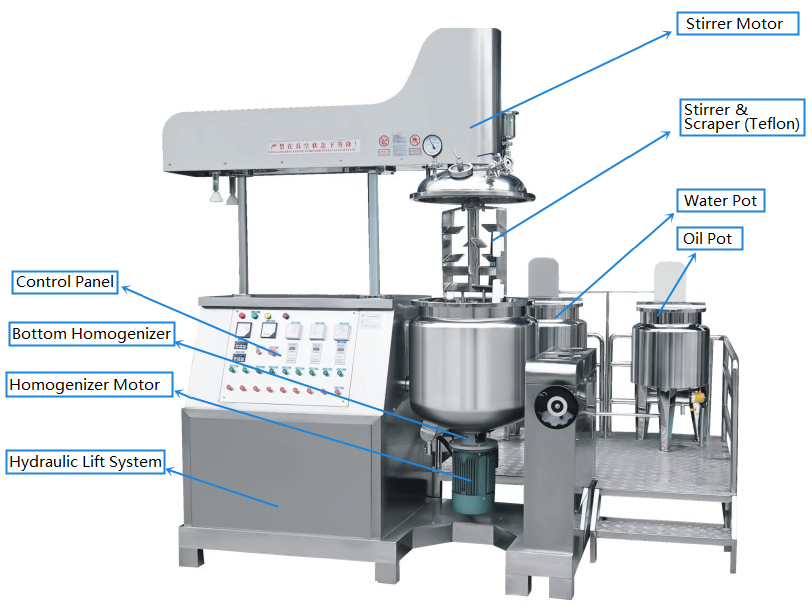

Hydraulic Lifting Vacuum Emulsifying Mixer Machine Liquid Soap Making Machine

Features

JF-A Vacuum Homogenizer Emulsifier introduces foreign advanced technology and is professionally designed according to the ointment process of cosmetics and ointment products. This unit consists of pretreatment pot, vacuum emulsification stirring pot, vacuum pump, hydraulic system, feeding system, electrical appliances Control system, working platform and other parts. The unit is easy to operate, stable in performance, good in homogeneous performance, high in production efficiency, convenient in cleaning, reasonable in structure, small in floor space and high in automation.

Advantage

The unit adopts the upper coaxial three-heavy agitator, the hydraulic lifting and opening cover, the speed of the fast homogenizing agitator: 0-3500r/min (frequency conversion speed regulation), the slow speed scraping wall agitator speed: 0-63r/min (frequency conversion speed regulation) ), the homogenizer adopts a high-shear eddy-type emulsification mixer, and the slow-speed wall scraping and stirring automatically adheres to the bottom and wall of the pot. Vacuum suction is adopted, especially for powder materials to avoid dust flying. The whole process is carried out under vacuum conditions to prevent the material from generating air bubbles after high-speed stirring, which can meet the requirements of sanitation and sterility. The system is equipped with a CIP cleaning system, the contact part between the container and the material is made of SUS316L material, and the inner surface is mirror-polished 300EMSH (sanitary grade). In order to ensure the stability of the control part, the vacuum pump adopts the product of Germany Nassim (formerly Siemens), and the button adopts Japan Fuji The company's products and frequency converters use Japan's Matsushita Electric Works, and the electrical control part uses Siemens products. This unit is manufactured in full compliance with GMP requirements, and is currently the most advanced and ideal production equipment for creams and creams in China.

Sample

Use

Vacuum emulsifying machine is an ideal option to produce high-grade skin care products, pharmacy ointment, and many other kinds of creams which need to be very soft and smooth. It has the functions of heating, mixing, scraping, rotating at different speeds and vacuum supply. It has a very wide application from cosmetics (skin cream, hair gel, lotion ect) and food (jam, chocolate, sauces ect) to ointment, syrup, paste and chemicals(painting, adhesives, detergents).The emulsifying effect is more prominent for materials of high base viscosity and high solid content .

Packing & Delivery

The Seller packs all of the machine and parts in the firm case that suitable for sea shipping

Hot Searches