- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

9000 KG

-

Coating method:

-

Rotary Bar Coating

-

Coating width:

-

500-2000mm

-

Coating speed:

-

2-200m/min

-

Base Material:

-

BOPP Film OPP Film

-

Glue type:

-

Hot Melt Pressure Sensitive Adhesive

-

Heating type:

-

Electrical Heating

-

Coating gsm:

-

10-20G/m2

-

Coating precision:

-

5%

-

Certification:

-

CE

Quick Details

-

Voltage:

-

380 V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

sanrenxing

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

9000 KG

-

Coating method:

-

Rotary Bar Coating

-

Coating width:

-

500-2000mm

-

Coating speed:

-

2-200m/min

-

Base Material:

-

BOPP Film OPP Film

-

Glue type:

-

Hot Melt Pressure Sensitive Adhesive

-

Heating type:

-

Electrical Heating

-

Coating gsm:

-

10-20G/m2

-

Coating precision:

-

5%

-

Certification:

-

CE

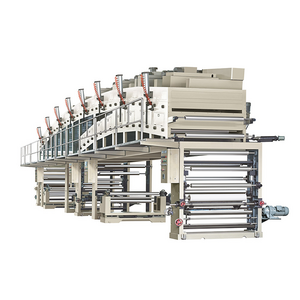

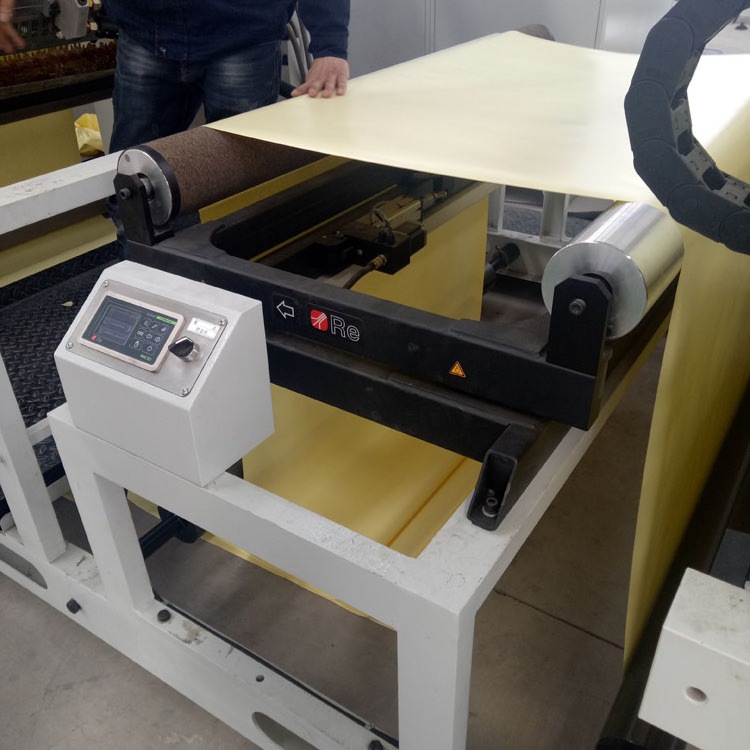

BOPP/OPP plastic adhesive tape making machine

BOPP tape coating machine, this equipment use hot melt adhesive coating, not traditional water glue coating machine. Hot melt adhesive bopp tape, bopp film need to do anti-stick treatment before adhesive coating, water glue coating needn't this process, but water glue coating need dry, it has oven for process, hot melt adhesive just coating, no oven. Hot melt adhesive energy consumption less, price cheaper than water glue coating machine.

Technical parameters

1. Rotary bar coating technology

2.Coating weight adjust, Min. 10g/m 2 .

3. Max. speed 350m/min .

5.Unwinder device motor frequency double position transfer unwind

6.Rewinder device motor frequency double position transfer rewind.

7.Coating precision 5%.

9 .Control method: PLC touch screen concentrate control.

10.Adhesive: hot melt PSA.

11.Max. temperature: 230 ℃ .

12. coating die head temperature be control l ed independently.

13. Could do strip coating/full coating.

14.Generator structure steel board thickness 80mm, will adjust thickness according configuration request.

15. Generator roller use import silica gel roller. Some transfer roller will use anti-stick roller(according product request).

16.Unwinder & rewinder diameter about 900-1300mm.

17. Install with guiding device, precision less than 0.3mm.

18.Unwinder install with hydraulic shaftless feeding device.

19.P LC control automatic double position transfer rewind, PLC control automatic cutting device.

20.Melt adhesive system inside wall use telflon anti-stick l ayer, three layers heating structure.

21. PID control heating, double over - temperature alarm outage system.

1.Reply within 24 hours

2.Welcome to contact us whenever you have a doubt or a question. Our strong technician and engineer team will work out the solution for you within 24 hours.

3.Warranty period: 12 months

![[JT-GW500-A6]Rewinding Bopp Adhesive Tape Making Machine Automatic Coating Plastic Film Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/cb9133af055b3ad7b962b5e60352dadb.jpg!/rotate/180/sq/300)