Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

15-35 punch/min

-

Warranty of core components:

-

2 Year

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 1 mm

-

Heating Power (kW):

-

2.2 kW

-

Air Comsumption(L/min):

-

0.7 L/min

-

Water Comsumption(L/min):

-

60 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mingyuan

-

Voltage:

-

380V/220V 50HZ

-

Dimension(L*W*H):

-

2900*1000*1800MM

-

Weight (T):

-

1.5 T

-

Power(KW):

-

8.2Kw

-

Punch speed:

-

15-35 punch/min

-

Max. Forming size:

-

430*300mm

-

Max. Forming depth:

-

Standard Type 46mm Max Target 60 MM

-

Max. Material width:

-

450mm

-

Stroke Range:

-

100-280mm

-

Compressed air:

-

0.4-0.7Mpa

-

Mold cooling:

-

60L/H tap water /recycle water

-

Total power:

-

8.2Kw

-

Main motor power:

-

2.2Kw

-

Material thickness:

-

0.15-1 mm

Quick Details

-

Max.Forming Height(mm):

-

50 mm

-

Forming Width (mm):

-

450 mm

-

Forming Length (mm):

-

50 mm

-

Production Speed(Cycles/min):

-

15-35 punch/min

-

Warranty of core components:

-

2 Year

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 1 mm

-

Heating Power (kW):

-

2.2 kW

-

Air Comsumption(L/min):

-

0.7 L/min

-

Water Comsumption(L/min):

-

60 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mingyuan

-

Voltage:

-

380V/220V 50HZ

-

Dimension(L*W*H):

-

2900*1000*1800MM

-

Weight (T):

-

1.5 T

-

Power(KW):

-

8.2Kw

-

Punch speed:

-

15-35 punch/min

-

Max. Forming size:

-

430*300mm

-

Max. Forming depth:

-

Standard Type 46mm Max Target 60 MM

-

Max. Material width:

-

450mm

-

Stroke Range:

-

100-280mm

-

Compressed air:

-

0.4-0.7Mpa

-

Mold cooling:

-

60L/H tap water /recycle water

-

Total power:

-

8.2Kw

-

Main motor power:

-

2.2Kw

-

Material thickness:

-

0.15-1 mm

sample size

The following examples are for reference only. If you still have any questions about the size, please feel free to contact us. We will do our best to provide you with professional advice and support.

Products Description

1. High-speed production capacity:

15-35punch/min per minute, improving production efficiency

2. Servo motor: The feeding of plastic sheets is controlled by a large servo motor to

ensure more accurate and stable feeding.

3. Forming mold:

The forming mold is durable and suitable for different plastic products

4. Forming molds can be customized according to different sizes, easy to replace, punching molds are durable and have no burr problems

5. The above are the characteristics of the DPP-420G plastic cup lid machine.

Its high-speed production capacity is suitable for different plastic products, it is convenient to change the mold, and it runs stably and accurately. It is an ideal choice for the plastic cup lid machine.

|

Machine

|

Plastic Thermoforming Machine

|

|

|

|

Model

|

DPP-450W

|

DPP-420G

|

|

|

Punch Speed

|

15-35 punch/min

|

15-35 punch/min

|

|

|

Max.Forming size

|

430*300mm

|

430*150mm

|

|

|

Max. Forming depth

|

Standard Type 46mm Max Target 60 MM

|

|

|

|

Max.Material width

|

450mm

|

450mm

|

|

|

Stroke Range

|

100-280mm

|

65-165mm

|

|

|

Compressed Air

|

0.4-0.7Mpa

|

0.6-0.8Mpa

|

|

|

Mold Cooling

|

60L/H tap water /recycle water

|

|

|

|

Total Power

|

8.2Kw

|

4.5Kw

|

|

|

Material Thickness

|

0.15-1 mm

|

0.15-0.5*340mm

|

|

|

Overall Dimension

|

2900*1000*1800MM

|

2500*1000*1700mm

|

|

|

Packing Size

|

3100*1100*1900MM

|

2150*1060*1750MM

|

|

|

Weight

|

1500 KG

|

1000 KG

|

|

|

Voltage

|

380V/220V 50HZ

|

|

|

Product details

Electric System

High stability of in ovance PLC control system and Schneider brand Electric system of the machine components to achieve reliable quality and easy maintenance

Selling Point of a Product

Touch Screen

It adopts PLC controller and touch screen (man -machine interface)all the working parameters can be set up on the control panel which is convenient for parameter setting and adjusting.(easy to operate)

Servo Motor

The plastic sheets feeding is controlled by a large servo motor to ensure feeding more accuratly and more stably

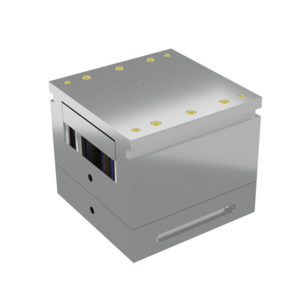

Mould

Durable Forming mould which can be customized for different sizes of production is easy to be changed .punching mould are durable and no cutting burr troubles

Big Air Cylinder

Circular holes ,crossed holes ,different options are available

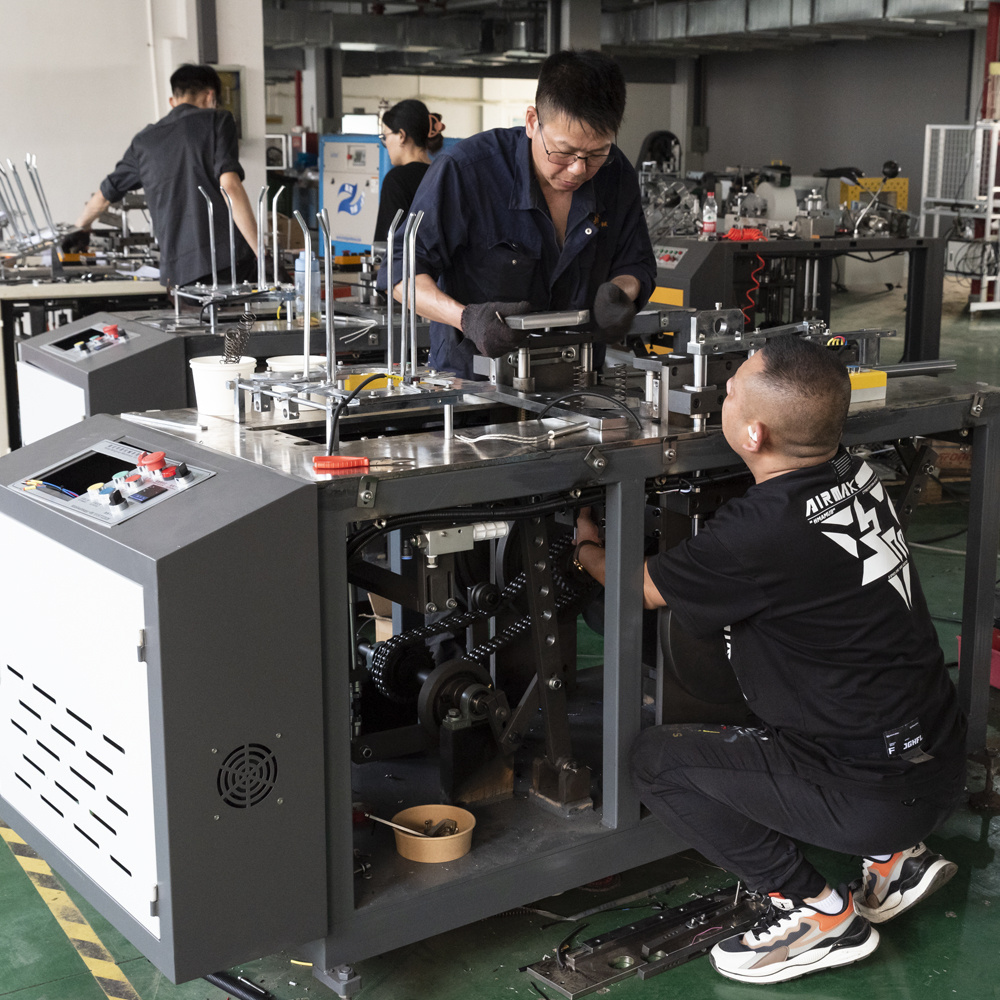

Company strength

FREE TOOLS,REPLACEABLE PARTS

we supply more replaceable parts to client to replace the broken spare parts and help client save money and time to buy it

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Hot Searches