- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JK-0397

-

Item:

-

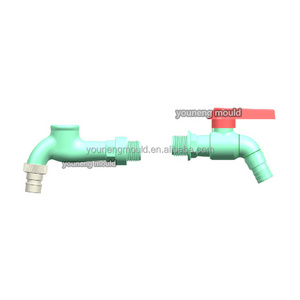

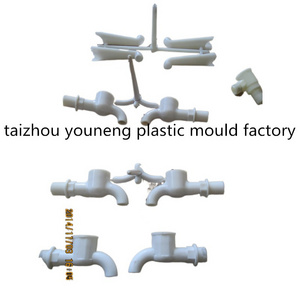

plastic water tap mould for kitchen

-

Cavity:

-

single/multi

-

Runner:

-

cold/ hot runner - point way, side way, follow way, direct gate way

-

Design software:

-

UG,PROE,CAD

-

mould material:

-

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

-

mould life:

-

1million shots

-

Surface Treatment:

-

polishing

-

MOQ:

-

1 set

-

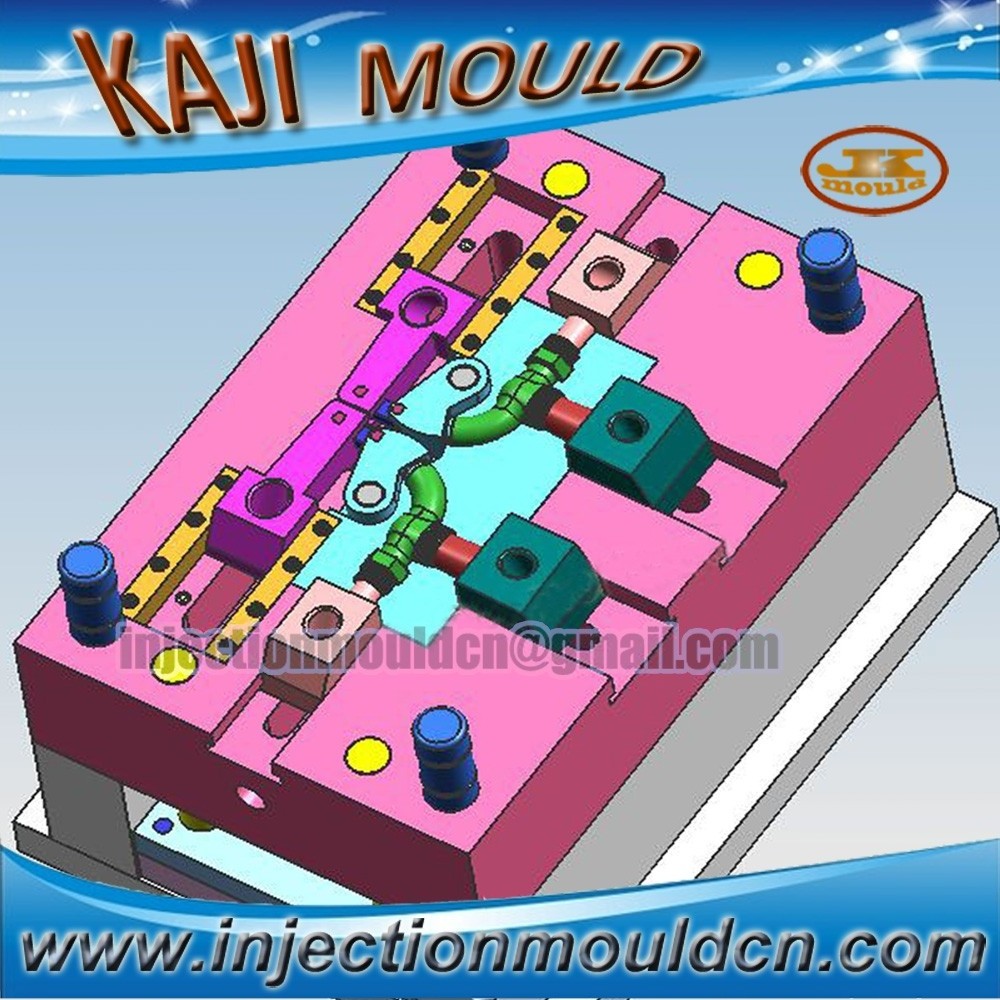

Mould:

-

Plastic Injection Mould

-

Mould base:

-

HASCO standard, European standard, World standard

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KJ MOULD

-

Model Number:

-

JK-0397

-

Item:

-

plastic water tap mould for kitchen

-

Cavity:

-

single/multi

-

Runner:

-

cold/ hot runner - point way, side way, follow way, direct gate way

-

Design software:

-

UG,PROE,CAD

-

mould material:

-

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

-

mould life:

-

1million shots

-

Surface Treatment:

-

polishing

-

MOQ:

-

1 set

-

Mould:

-

Plastic Injection Mould

-

Mould base:

-

HASCO standard, European standard, World standard

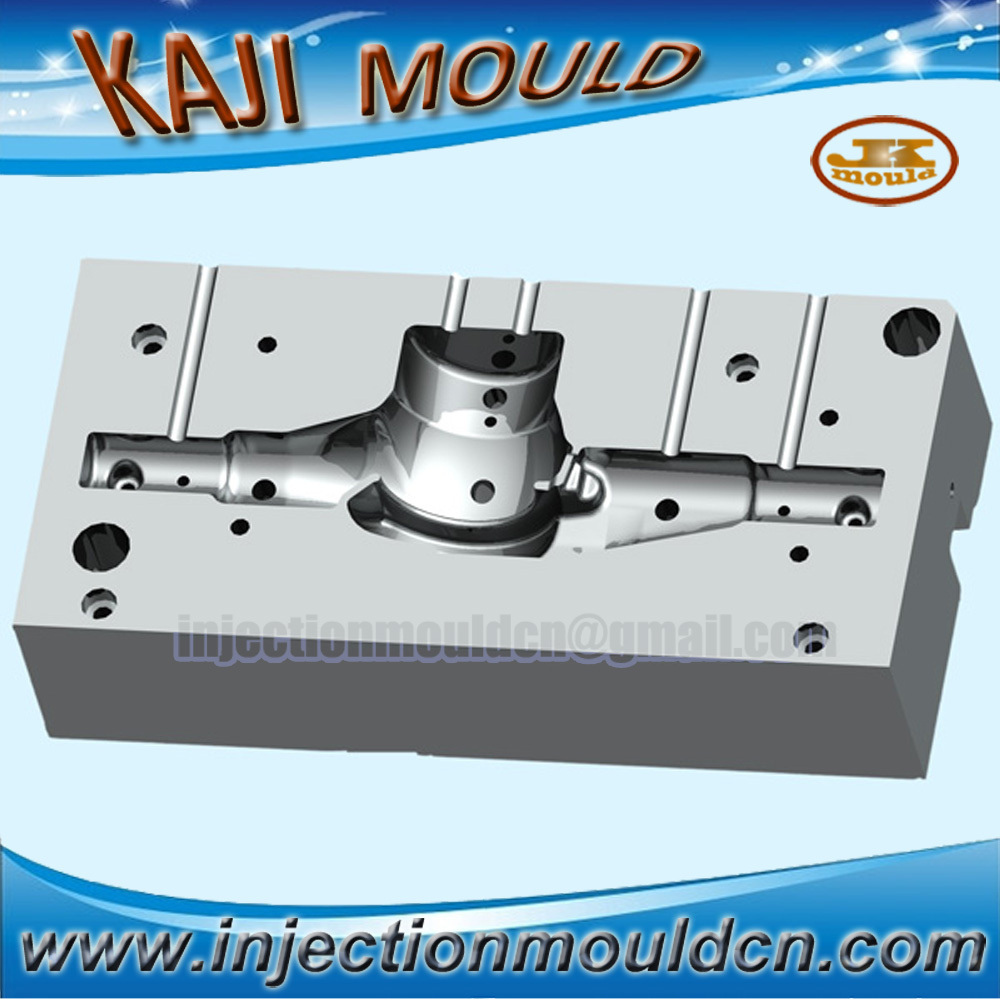

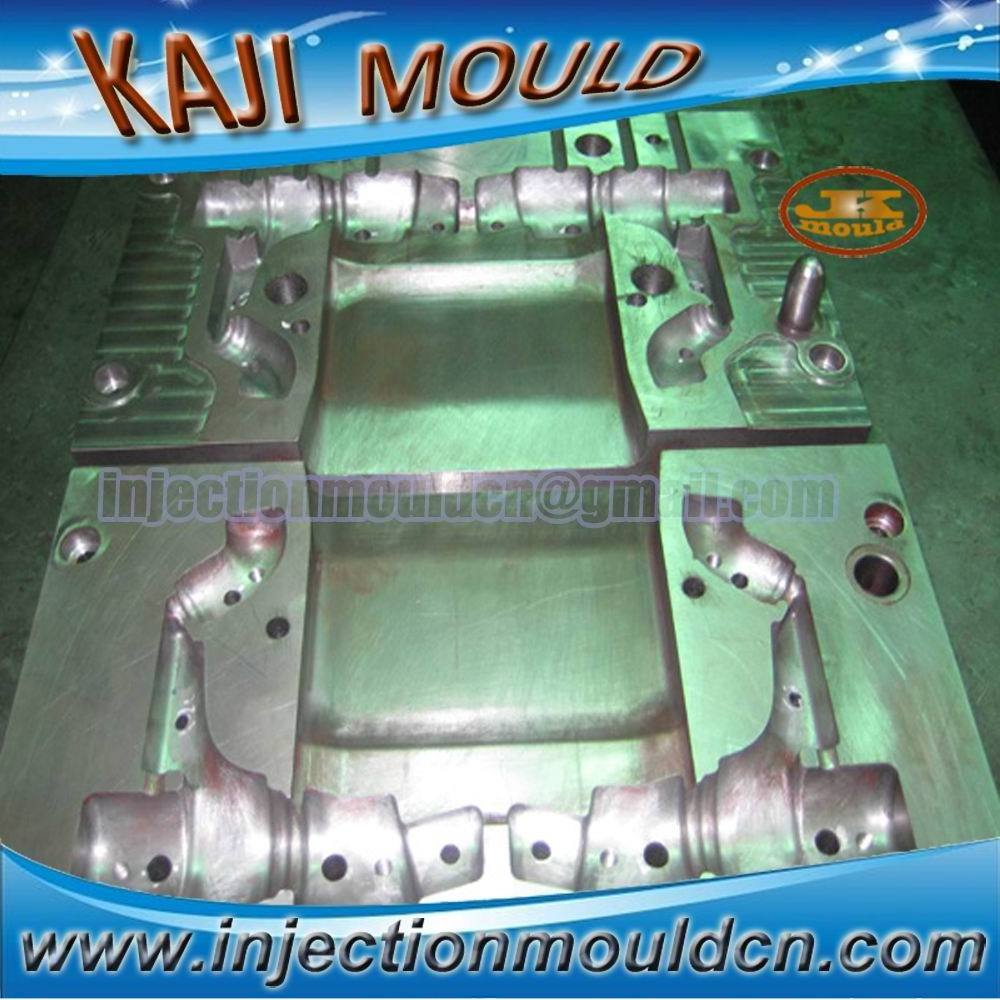

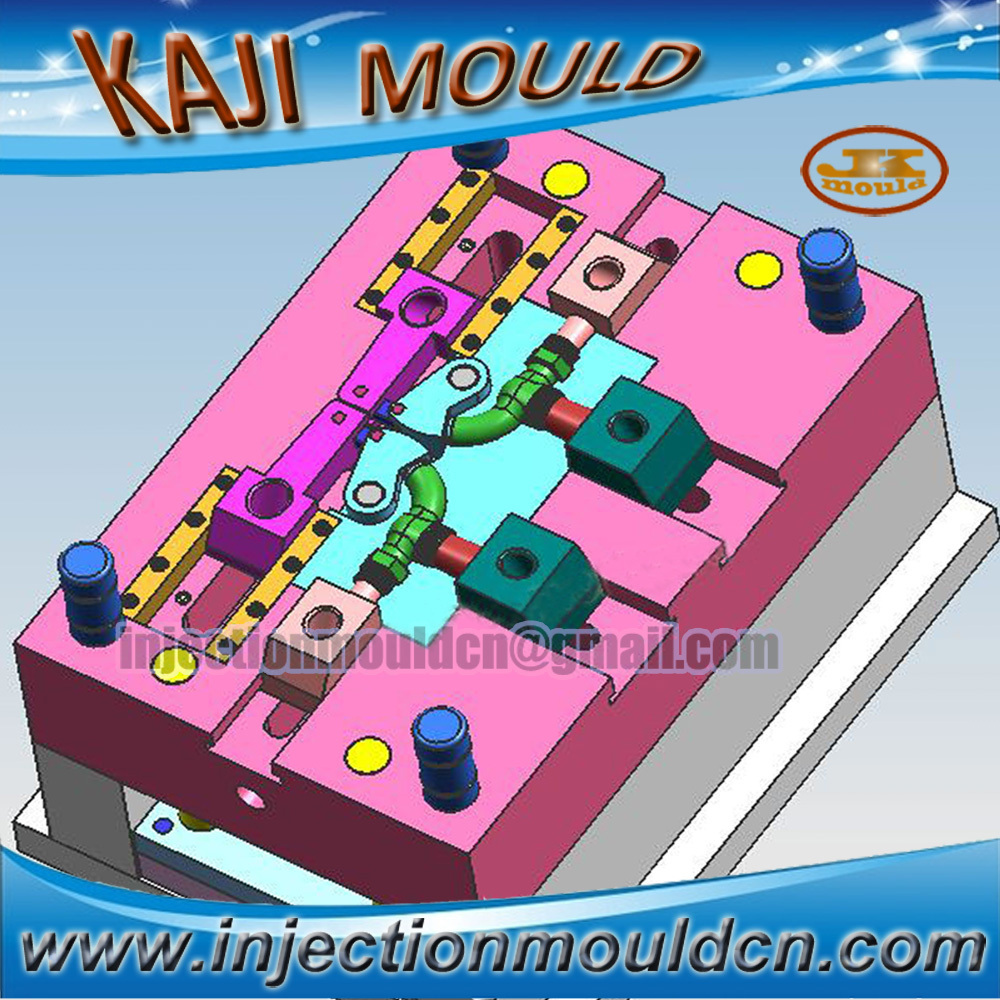

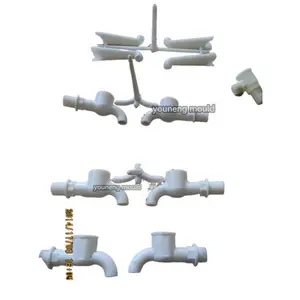

pvc water tap mold making mold manufacturer plastic water tap mould for kitchen

We can produce kinds of moulds for customers as their special demand. Quotations will be based on drawings or samples provided by customers. Best quality and economic price, our products are guaranteed.

|

Name |

Description of plastic water tap mould for kitchen |

|

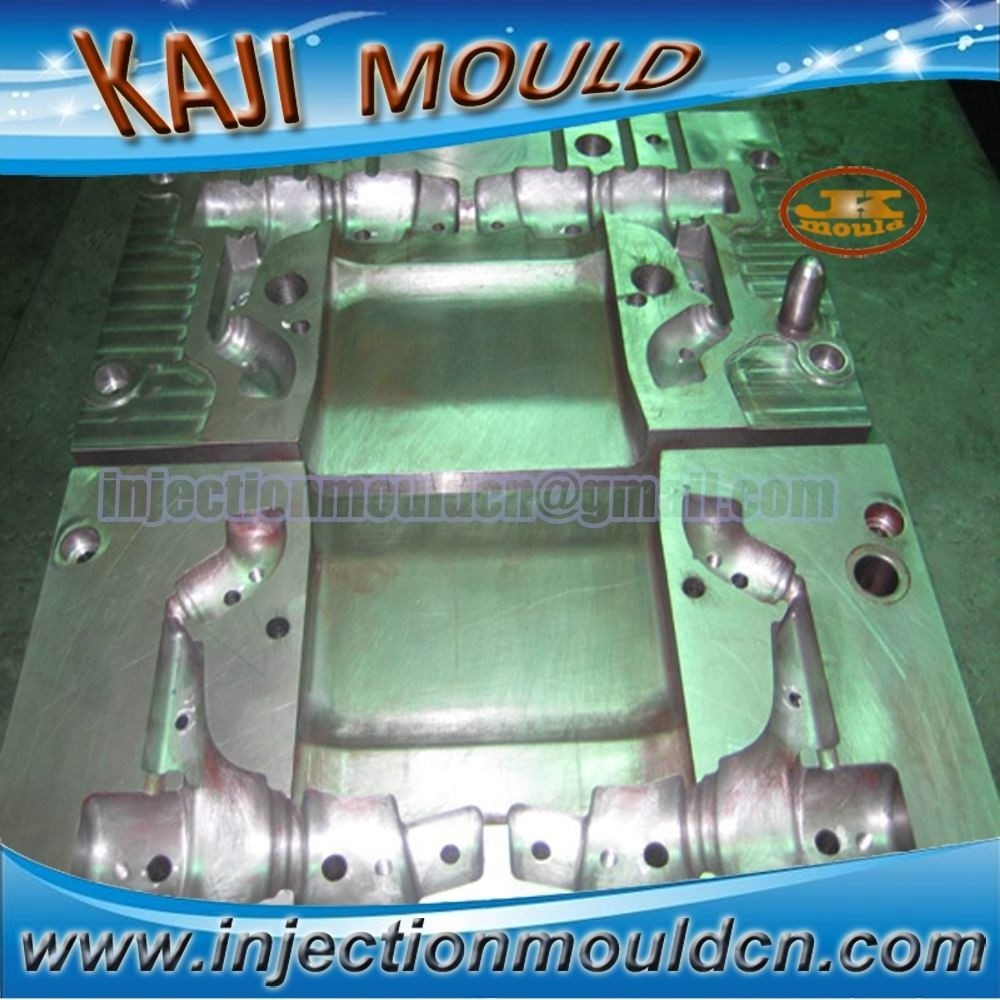

Mould material |

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.(Hardness 35~55HRC) |

|

Mould base |

Standard mould base,LKM, HASCO ect. |

|

Cavity |

Single/multi |

|

Runner |

Hot/cold |

|

Ejection system |

Motor/hydraulic cylinder/stripping plate/angle pin,etc |

|

Cooling system |

In core baffle and in cavity plate chain drilling type cooling |

|

Design software |

UG, PROE, CAD, CAXA ect. |

|

Plastic material |

PP, PC, PS, PE, PU, PVC, ABS, PMMA ect. |

|

Surface treatment |

Polish,texture,sandblasting,chrome |

|

Mould life |

300,000-5,000,000 shots |

|

Delivery time |

15-75days |

|

Pacakge |

Standard export wooden case |

|

Specification |

Depends on customer's requirements. |

Packing details of pvc water tap mold making mold manufacturer plastic water tap mould for kitchen

1.Check plastic injection mould component

2.Cleaning mould cavity/core and spread slushing oil on the mould

3.Cleaning mould surface and spread slushing oil on the mould surface

4.Put into the wooden case

KAJI MOULD SERVICE for pvc water tap mold making mold manufacturer plastic water tap mould for kitchen

|

In-time response on letters, telephone calls or fax |

|

In-time supply the mould designs |

|

In-time communication on the technical points |

|

In-time sending pictures for the mould machining progress and mould finishing schedule |

|

In-time mould test and sample delivery |

|

In-time mould delivery. |

|

Mould one year guarantee,full life technique support |