- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HN-PCB-300

-

Power:

-

102

-

Weight (KG):

-

15000 kg

-

Name:

-

PCB Recycling Machine

-

Application:

-

E Waste Treatment

-

Function:

-

Crushing and separating

-

Advantage:

-

High Separator Rate 99.99%

-

Capacity:

-

100-1000kg/h

-

Suitable for:

-

Municipal Waste Management Project

-

Feature:

-

Environment Protection

-

After Sale Service:

-

Engineer Overseas Service

-

Installation:

-

Engineer Guide

-

Voltage:

-

380V(can Customized)

Quick Details

-

Production Capacity:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Honest

-

Model Number:

-

HN-PCB-300

-

Power:

-

102

-

Weight (KG):

-

15000 kg

-

Name:

-

PCB Recycling Machine

-

Application:

-

E Waste Treatment

-

Function:

-

Crushing and separating

-

Advantage:

-

High Separator Rate 99.99%

-

Capacity:

-

100-1000kg/h

-

Suitable for:

-

Municipal Waste Management Project

-

Feature:

-

Environment Protection

-

After Sale Service:

-

Engineer Overseas Service

-

Installation:

-

Engineer Guide

-

Voltage:

-

380V(can Customized)

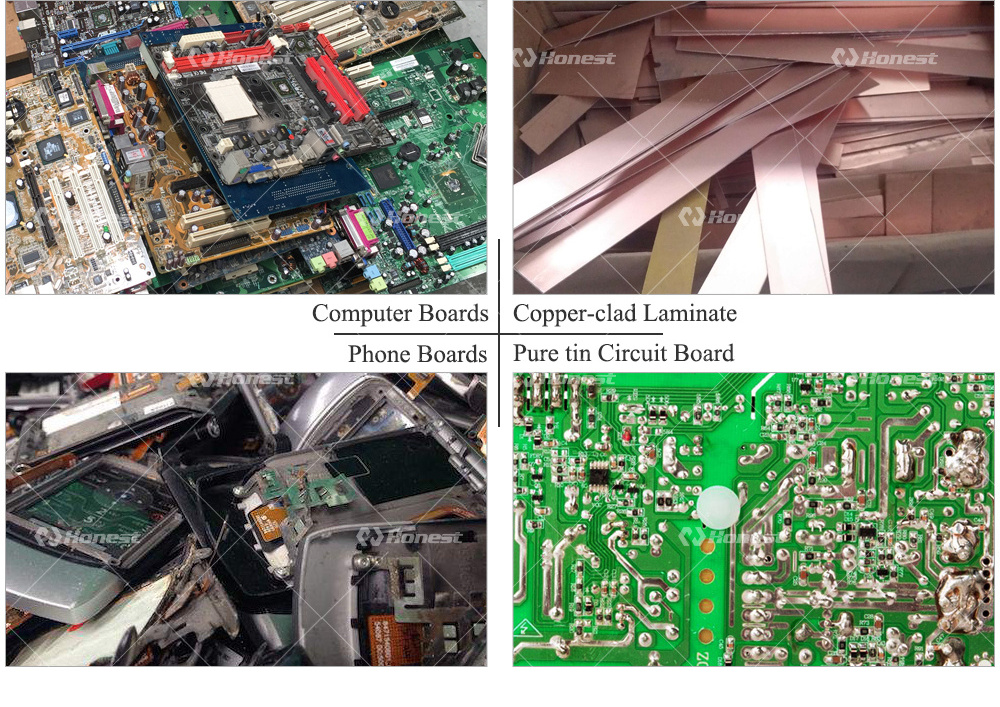

Product Application

Waste PCB Recycle Plant is used to recycle all kinds of Printed Circuit boards, such as the computer boards, cell phone boards, TV boards, copper-clad laminate, and other household appliances, and the separation of leftover material of the mixed metal and nonmetal materials.

Final Products

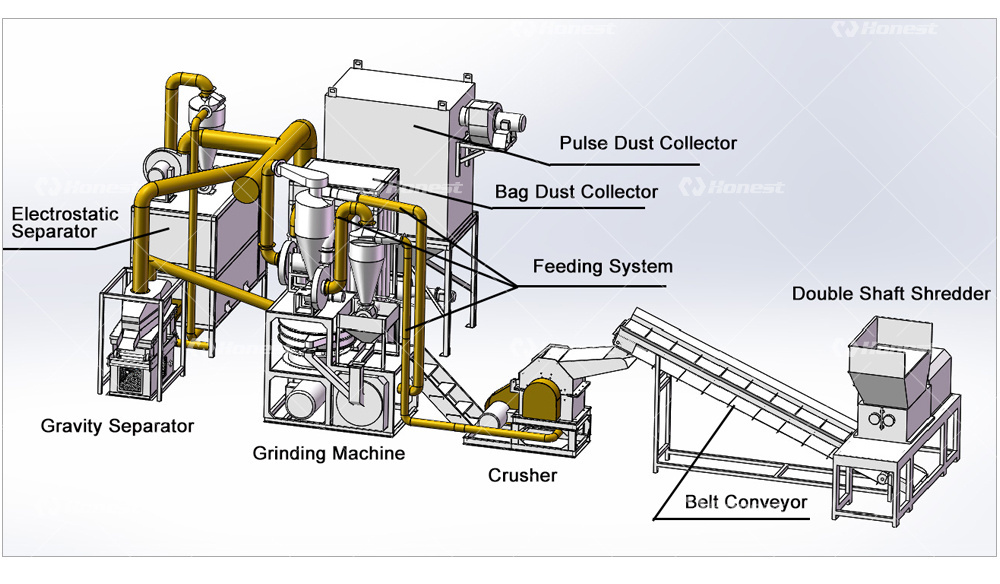

Product Structure

Process Description

we use the hammer crusher, and the third crushing machine we use the high speed turbinegrinding

machinc, the matcrial after shredding,crushing and grinding will be separated by the airseparator

and the electrostatic separator .It has the advantages of unique structure, large output andpower

saving.

Several machines cooperation work after single loading of materials. Controlled byPLC This machine has good performance in copper recycling and comes with a device to preventagainst

secondary pollution The metal recycling rate is up to 99% which is the only in china.

Technical Parameters

|

Model

|

Power (Kw)

|

Weight (Kg)

|

Size (m)

|

Capacity (Kg/H)

|

|

HN-PCB-300

|

102

|

15000

|

20*5*5

|

200-300

|

|

HN-PCB-500

|

134

|

20000

|

25*6*5

|

400-500

|

|

HN-PCB-700

|

194

|

30000

|

30*6*5

|

600-700

|

|

HN-PCB-1000

|

238

|

40000

|

35*8*5

|

800-1000

|

Product Feature

2. PLC system makes it casier to control the whole line.

3. Recycling water is used to control temperature and reduce noise in the grinder.

4. The negative pressure feeding system prevent the dust from running out.

5. The separation rate of air separator can reach 97%.

6. The separation ratc of pulsc dust clcaning device can rcach 99%.

7. Electrostatic separator makes higher and quicker separation, moreover gets more non-ferrousmetal.

8. With the magnetic separator, the iron can be separated from other metals.

Customer Site

Delivery

Quality Assurance

Company Show

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Hot Searches