- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2520*1840*2303

-

Weight:

-

1000 KG

-

Input Size:

-

0-1020mm

-

Color:

-

Grey

-

Material:

-

Granite, marble, basalt, limestone

-

Model:

-

pex 300x1300 jaw crusher

-

Keyword:

-

pex 300x1300 jaw crusher

-

Spare parts supply:

-

Anytime

-

Maximum feeding size:

-

500mm

-

Range of discharge opening:

-

65-160mm

-

Speed (r/min):

-

250

-

Product name:

-

jaw crusher for sale craigslist

Quick Details

-

Application:

-

mining;road;aggregate;concrete

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZENITH

-

Dimension(L*W*H):

-

2520*1840*2303

-

Weight:

-

1000 KG

-

Input Size:

-

0-1020mm

-

Color:

-

Grey

-

Material:

-

Granite, marble, basalt, limestone

-

Model:

-

pex 300x1300 jaw crusher

-

Keyword:

-

pex 300x1300 jaw crusher

-

Spare parts supply:

-

Anytime

-

Maximum feeding size:

-

500mm

-

Range of discharge opening:

-

65-160mm

-

Speed (r/min):

-

250

-

Product name:

-

jaw crusher for sale craigslist

Hot Sale Jaw Crusher Plant Pex 300X1300 Jaw Crusher

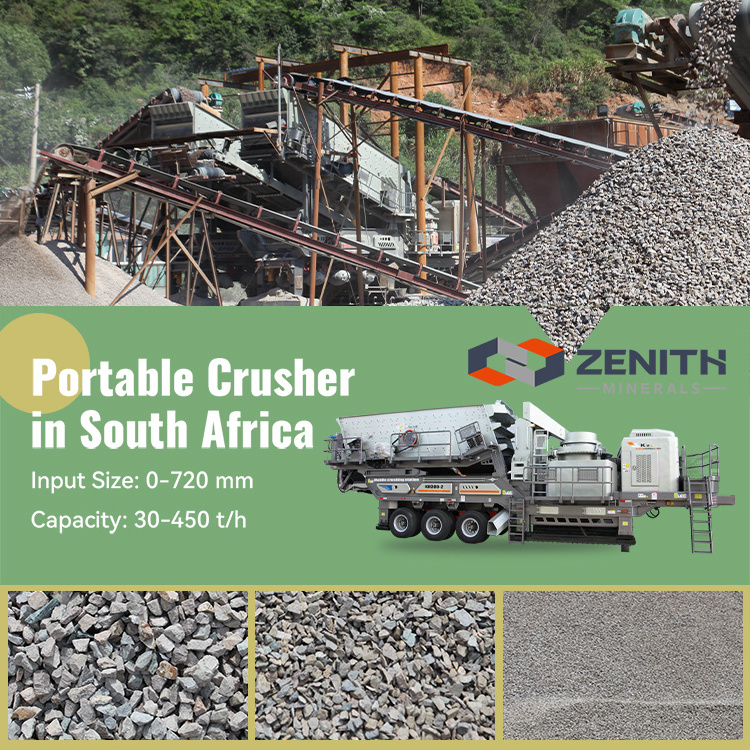

ZENITH has helped over 50 Philippine partners with their business in processing river stone, basalt, limestone, vibro sand, copper and gold ore in Luzon, Visayas and Mindanao.

Most of our crushing plants in Philippines are around 100-500t/h. A crushing plant can produce cubic aggregates within 0-5-10-20-31mm simultaneously.

ZENITH has an office in Manila, where our engineers can provide customers nearby a solution within 24 hours.

At present, we are building a spare parts warehouse in Philippines which will cut down costs greatly possibly caused by downtime.

Click to know more about pex 300x1300 jaw crusher>>>

|

|

Hot Sale Jaw Crusher Plant Pex 300X1300 Jaw Crusher

Product Features: Inheritance of century-old classics, simple structure, stable working performances

Input Size:

0-1020mm

|

Hot Sale Jaw Crusher Plant Pex 300X1300 Jaw Crusher introduction:

|

Classic Inheritance, Simplicity & Reliability

|

"Power Failure" Safety Device Effectively Responds To Overload

|

|

Shorter Downtime &Longer Service Life - Super-Strong High-Manganese Steel Casting

|

Precise Processing, Craftsmanship Spirit

|

|

Various Models To Satisfy More Demands

|

Sufficient Supply Of Spare Parts, Worry-Free Operation

|

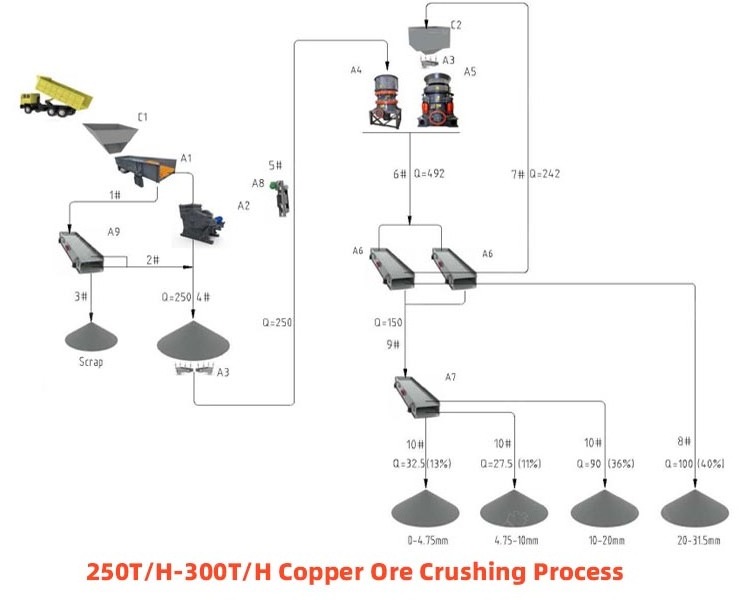

pex 300x1300 jaw crusher working principle:

The pex 300x1300 jaw crusher is powered by the motor. Through the motor pulley, the eccentric shaft is driven by the V-belt and the sheave, so that the movable jaw reciprocates along the predetermined tracks to crush materials inside the crushing cavity. Materials, after being processed and reaching the standard, would be discharged from the lower discharge opening.

Hot Sale Jaw Crusher Plant Pex 300X1300 Jaw Crusher photos:

Hot Sale Jaw Crusher Plant Pex 300X1300 Jaw Crusher parameters:

| Model | Feed opening (mm) | Maximum feeding size (mm) | Range of discharge opening (mm) | Capacity (t/h) | Speed (r/min) | Power (kw) | Overall dimension (mm) |

| PE500×750 | 500×750 | 425 | 50-100 | 45-100 | 275 | 55 | 1890×1916×1870 |

| PE600×900 | 600×900 | 500 | 65-160 | 70-120 | 250 | 75 | 2520×1840×2303 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 130-260 | 250 | 90 | 2620×2302×3110 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 130 | 3789×2826×3025 |

| PE1000×1200 | 1000×1200 | 850 | 195-265 | 230-380 | 200 | 130 | 3889×2826×3025 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 220 | 200 | 4930×3150×3700 |

Note:

1.The bulk specific weight is calculated by 1.6t/m³. When the width of the feeding port is above 600mm, it is a large-scale machine while when the width ranges from 300 to 600mm, it is a medium-sized machine.

2.Product pictures and parameters about models, data, performances and specifications on this website are for reference only. There is a chance that ZENITH may make changes on above-mentioned information. For specific messages, please refer to the real objects and user manuals. Without special instructions, Z keeps the right to explain all data involved in this website.

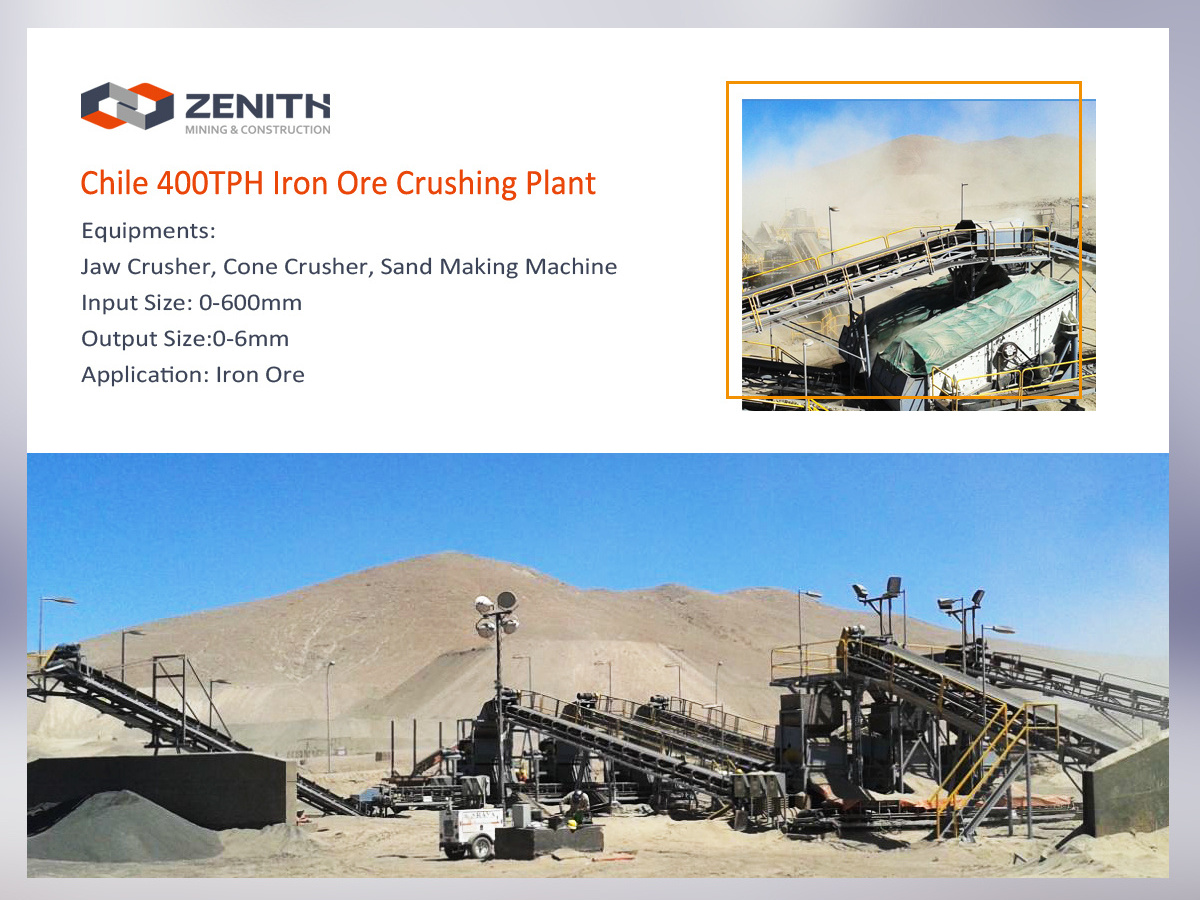

Project Background:

Raw Material: Kenya Phonolite

Location : Isiolo

Capacity: 100-120 TPH (8 hours per day)

Input sizes: 0-500mm

Final output sizes: 0-6mm, 6-10mm, 10-14mm, 14-20mm.

Installation Time: Jun, 2016

Foundation Type: Steel Structure Foundation

Customer Feedback:

“ My friend introduced me to ZENITH. With their professional advice, I start to prepare the land, license and look for partner. I place the order even without visiting their China factory as they have local office here and a lot of customers in Kenya. Against the inspection opportunity, I visited their headquarters and factory in Shanghai and was quite impressed on their strength. I am very happy I choose the right company to work together and I catch the early developing train in my hometown.’’

|

Pre-sales Service: The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit zenith working machines or complete plant in the site. To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

|

|

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

|

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival