- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YBKE

-

Voltage:

-

380v 50hz

-

Power:

-

20kw

-

Weight:

-

3500 kg

-

Product name:

-

Glass Making Machine

-

min. glass size:

-

300X400mm

-

max. in washing section:

-

12m/min

-

Thickness:

-

3mm-19mm

-

insulating glass thickness:

-

50mm

-

Application:

-

Insulating Glass Double Glazing Making

-

Brand:

-

ybke

-

Advantage:

-

Easy Operatioin

-

Seaport:

-

Qingdao Port

Quick Details

-

Machine Type:

-

Insulating Glass Production Line

-

Glass Thickness:

-

3-18mm

-

Production Capacity:

-

500 SETS ONE YEAR

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YBKE

-

Voltage:

-

380v 50hz

-

Power:

-

20kw

-

Weight:

-

3500 kg

-

Product name:

-

Glass Making Machine

-

min. glass size:

-

300X400mm

-

max. in washing section:

-

12m/min

-

Thickness:

-

3mm-19mm

-

insulating glass thickness:

-

50mm

-

Application:

-

Insulating Glass Double Glazing Making

-

Brand:

-

ybke

-

Advantage:

-

Easy Operatioin

-

Seaport:

-

Qingdao Port

Product Description

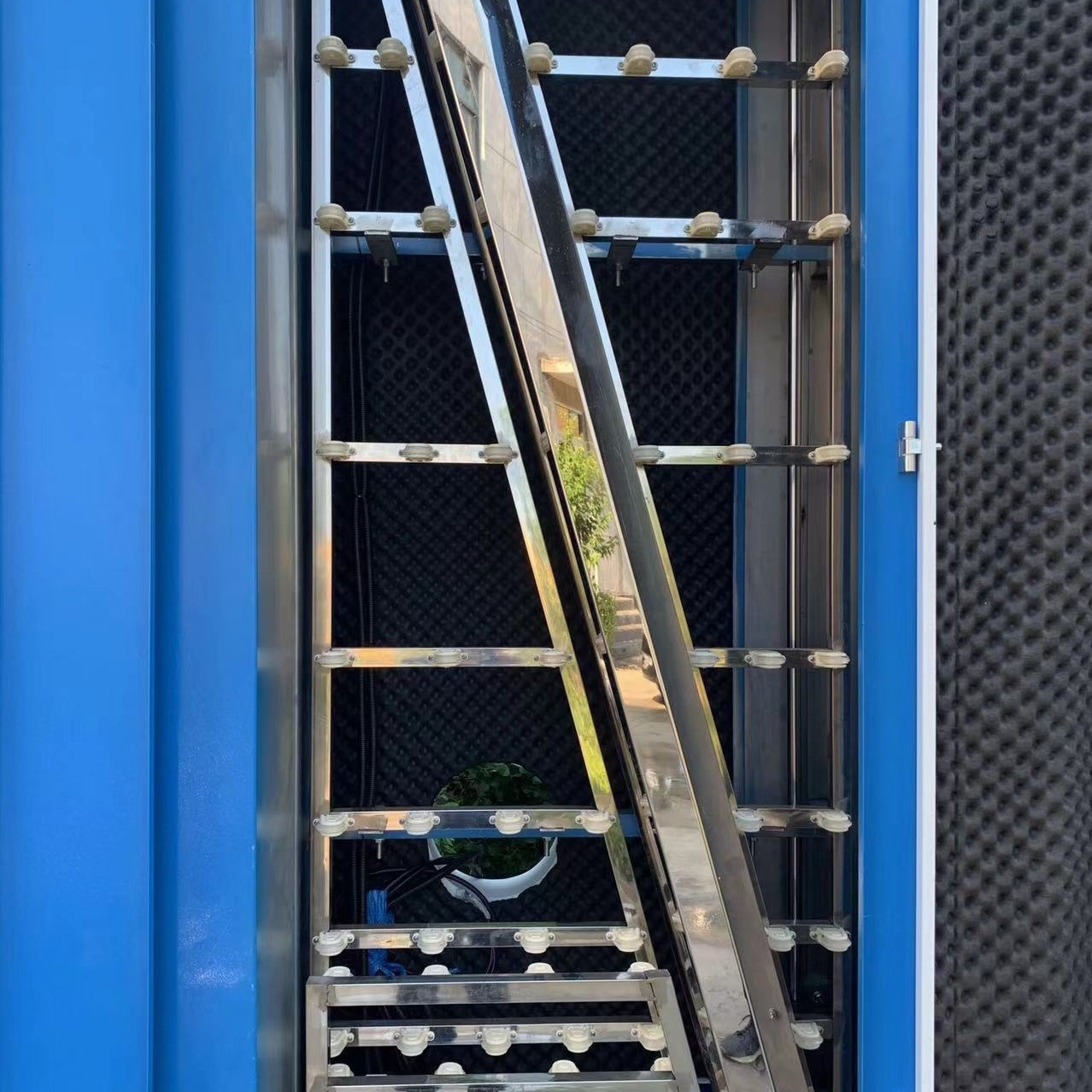

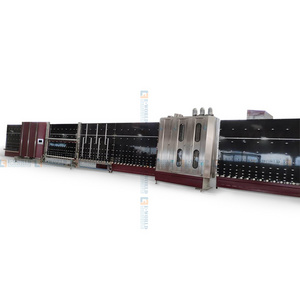

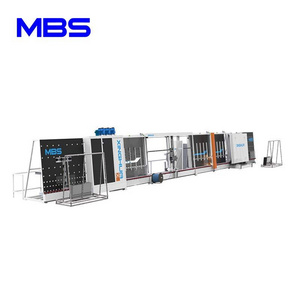

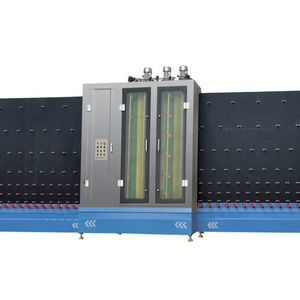

Double Glazing Glass Machinery Automatic Insulating Glass Production Line Window Glass Making Machine

Assembly with gas filling!

Automatic detection of Lowe glass, coated glass!

3 pairs of Low-e brushes!

Stainless steel air knife and sllencer cotton!

High and low speed conversion!

Automatic measurement of glass height and thickness!

Servo motor control far assembly!

Thickened aluminum air knife, low noise, fast heating, and good air-drying effect.

3 pairs of built-in brushes and 6 rubber rollers

It can clean lowe glass

Servo motor

LOWE glass inspection device

.

Use brand-name motors such as low-voltage electrical appliances from Schneider,

inverter adopts theJapan panasonic brand,t

he main electrical switch is ABB Switzerland

.

The large frame uses 50mm × 100mm square steel tube, the equipment is more stable, enhance the stability of equipment operation.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Power voltage

|

380v 50hz

|

|

2

|

power rate

|

20kw

|

|

3

|

insulating glass thickness

|

50mm

|

|

4

|

washing glass thickness

|

2-15mm

|

|

5

|

size of line

|

customizable

|

|

6

|

max. in washing section

|

12m/min

|

|

7

|

max. glass size

|

customizable

|

|

8

|

min. glass size

|

300X400mm

|

Our Company

Jinan YBKE Machinery Co., Ltd. is a high-tech enterprise specializing in the research and development, production and sales of insulating glass equipment, insulating glass production line, insulating glass automatic gluing machine, insulating glass processing equipment and export trade insulating glass machinery.Adhering to the professional, dedicated and dedicated working attitude, the company is constantly innovating and daring to challenge, has broken through one technical problem after another, and is striving to create a famous brand of insulating glass equipment respected by the global glass industry.

The company mainly produces research and development: insulating glass equipment, insulating glass production line, insulating glass machine, insulating glass machinery, insulating glass automatic gluing machine, automatic sealing line and other products.

Integrity comes from our responsibility and respect to customers, quality comes from our demanding and testing of each product, and innovation comes from countless explorations and tests before our products are put into production. Since its establishment, the company has insisted on quality and made the best insulating glass machines, which has won consistent praise from domestic and foreign customers.Our products are exported to more than ten countries and regions such as Europe, America, Africa and India.It is our greatest satisfaction to let China's mature high-end insulating glass equipment go abroad and get the recognition and trust of international users.

Letting the world fall in love with Made in China is a challenge, a feeling and a responsibility."Professionalism determines quality, strength creates brand" Jinan YBKE Machinery is willing to join hands with you to create brilliance!

Exhibitions

PACKING AND DELIVERY

PACKING:

1.For full container load, usually wrapped in stretch films.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water.

3.For less than container load, iron frame fixed or standard export plywood case.

DELIVERY:

* Small and few machines: in 5-10 days after receiving pre-payment.

* Big or many machines: more than 25 days after receiving pre-payment.

1.For full container load, usually wrapped in stretch films.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water.

3.For less than container load, iron frame fixed or standard export plywood case.

DELIVERY:

* Small and few machines: in 5-10 days after receiving pre-payment.

* Big or many machines: more than 25 days after receiving pre-payment.

Hot Searches