- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

Customized

-

Weight (KG):

-

11000 KG

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Lith

-

Voltage:

-

3*380V,50HZ

-

Dimension(L*W*H):

-

3700*1600*3570mm

-

Power (kW):

-

103 kW

-

Marketing Type:

-

Hot Product

-

Vacuum degree:

-

-0.098MPa

-

Revolution:

-

0~28 rpm

-

Rotation:

-

0~53 RPM

-

High speed:

-

0~2000rpm

-

Temperature measurement method:

-

1000mm

-

Power Supply:

-

103KW

-

Weight:

-

11T

-

Volume (L):

-

807L

Quick Details

-

Barrel Volume (L):

-

807

-

Max. Loading Volume (L):

-

807 L

-

Range of Spindle Speed(r.p.m):

-

0 - 2000 r.p.m

-

Max. Loading Capacity:

-

Customized

-

Weight (KG):

-

11000 KG

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Lith

-

Voltage:

-

3*380V,50HZ

-

Dimension(L*W*H):

-

3700*1600*3570mm

-

Power (kW):

-

103 kW

-

Marketing Type:

-

Hot Product

-

Vacuum degree:

-

-0.098MPa

-

Revolution:

-

0~28 rpm

-

Rotation:

-

0~53 RPM

-

High speed:

-

0~2000rpm

-

Temperature measurement method:

-

1000mm

-

Power Supply:

-

103KW

-

Weight:

-

11T

-

Volume (L):

-

807L

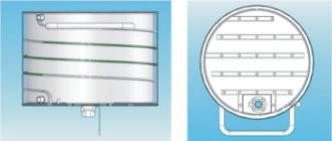

650L Double Planetary Mixing Machine Automatic High Speed Mixer Equipment for Sodium-Ion Battery Electrode Slurry Production

Planetary power mixer is an all-round new model which combines the principle and composition of traditional double planetary mixer and high-speed disperser. At present, it is widely used in many fields.

Aiming at the characteristics of high solid content and high viscosity of power battery slurry, our company has developed an enhanced power mixer with higher speed and greater torque based on the original star power mixer. In the design process, the factors such as the speed of the agitator, mixing power, dispersion linear speed, suspension grade, liquid flow pattern and the distribution of turbulence intensity in the barrel are fully considered. The highest linear speed of its high-speed dispersion can reach 23m/s, and the enhanced fried dough twist frame can handle any high viscosity battery slurry. A new mixing method - the fried dough twist box rotates clockwise and its rotation is counterclockwise to ensure that there is no dead angle and no "Climbing" phenomenon in mixing. In terms of sealing, two sets of mechanical seals plus soft and static seals ensure vacuum - theoretically, the sealing performance is enhanced by 30%. PT 100 temperature sensor directly contacts the material, so the measurement is more accurate and the reaction speed is faster, and the error is only between ± 0.5 ℃. This machine is composed of base, beam, column, sealing cover, feeding cylinder, transmission and electric control system.

Technical Parameters

|

Vacuum degree |

-0.098MPa |

|

Structural style |

Gantry type |

|

Speed r/min |

Revolution: 0~28 rpm, rotation: 0~53 RPM variable frequency speed regulation energy saving control; |

|

Low speed shaft |

High speed: 0~2000rpm variable frequency speed regulation energy saving control. |

|

High speed shaft |

Two axis hemp pattern, |

|

Lifting mode |

Double high-speed shafts, two on the shaft Φ 230 dispersion tray. |

|

Lifting height |

Hydraulic can body lifting, linear guide double hydraulic lifting, with safety bolt, oil pump motor 3kw |

|

Temperature measurement method |

1000mm |

|

Can body positioning |

Temperature measurement of barrel wall. |

|

Total power (KW) |

The positioning block at the bottom of the barrel is used for positioning, and the flange structure is set on the kettle cover to ensure the central positioning. |

|

Power Supply |

103KW |

|

Overall dimension |

AC:3*380V,50HZ |

|

Size |

Length 3700, width 1600, height 3570 (mm) |

|

Weight |

11T |

Can Body

|

Kettle size (mm) (inner diameter x inner height) |

Φ1100×850, the roundness error of the liner is 0.2mm, and the smoothness of the liner reaches the mirror surface. |

|

Volume (L) |

807L |

|

Design pressure (MPA) |

Inner cylinder -0.098mpa, jacket 0.8MPa |

|

Design temperature (° C) |

-10~+100°C |

|

Main material |

SUS304 is in contact with the material, jacket: 304, bottom material: 304 stainless steel +q235-b |

|

Cylinder thickness (mm) |

Inner cylinder δ 10mm, jacket δ 5mm. |

|

Temperature regulation form |

The can body and bottom are equipped with jackets, which increases the cooling or heating area. The cooling water is automatically thermostatically controlled by the chiller. |

|

Discharging form |

Ball valve |

|

Mobile mode |

Manual |

|

Number of can bodies |

1 set |

Main Materials

|

Name |

Material |

|

Name |

Material |

|

Upper can body |

SUS304 |

Mixing shaft |

SUS304 |

|

|

Lower body |

SUS304 |

Agitated slurry |

SUS304 |

|

|

Jacket |

SUS304+Q235 |

Rack, base, etc |

Q235-B |

Kettle Cover Nozzle

|

Purpose |

Specifications |

Qty |

remarks |

|

Powder feeding port |

DN150 |

1 |

Quick opening type, with DN150 quick opening feeding port |

|

Mirror |

DN120 |

2 |

One of them is equipped with LED mirror light |

|

Vacuumize |

DN20 |

1 |

Toothed pneumatic ball valve |

|

Nitrogen filling port |

DN20 |

1 |

Toothed pneumatic ball valve |

|

Exhaust port |

DN20 |

1 |

Toothed pneumatic ball valve |

|

Spare port |

DN50 |

2 |

Flange interface |

|

Vacuum gauge port |

M20×1.5 |

1 |

Equipped with vacuum gauge: Y-100 type. |

|

Note: the upper can body is in a straight barrel shape, and the outer wall of the can body is polished smooth for easy cleaning. |

|||

Mixing Shaft and Blades

|

Low speed mixing shaft: the cross section of the two shaft fried dough twist mixing paddle is Pentagon, cast from pure stainless steel; High speed mixing shaft: |

|

2 high-speed shafts, two on the shaft Φ 230 dispersion plate (height can be adjusted arbitrarily). |

|

Pulp shaft and blade: the surface is polished. After five axis CNC machining center processing, ensure that the spiral line is consistent. The distance between mixing paddle and barrel bottom is 3-5mm, the distance between mixing paddle and barrel wall is 3-5mm, and the distance between paddle and paddle is 4-7mm. |

|

Shaft seal: mechanical seal structure. |

|

Planetary case 304 |

|

Note: 1. The design is suitable for the flat bottom mixing tank, and the slurry shaft design is reasonable and easy to clean. 2. The planet carrier body is designed with an overpressure balance hole. |

Electric Cabinet

|

Standard type |

|

the electric cabinet is forced cooled by air conditioner. The electric cabinet has temperature monitoring and over temperature alarm. It is controlled by computer and PLC. It can be manually controlled or programmed. The electric box is sealed. The dust, combustible gas and conductive powder in the production environment will not enter the electric cabinet, so as to ensure the normal operation of all electrical components in the electric cabinet and reduce the failure rate. |

|

the control power supply adopts DC 24V safety voltage. |

|

separate the automatic / automatic program control, and complete the operation and setting of the start, stop, lifting, operation time and vacuum degree of the equipment on the computer touch screen. The computer has a large memory capacity, which can store more than thousands of processes. It is easy to operate, and the display is dynamic and intuitive. The whole process of operation is monitored. The temperature, vacuum degree, speed and other operating curves are clear at a glance, and the alarm is visually recorded. A U disk can be inserted behind the computer to facilitate uploading / downloading the process and setting parameters. Permissions can be set to prevent operators from changing the process artificially and ensure the consistency of products. |

|

electronic motor overload thermal protection. |

|

if the motor has phase failure, grounding, etc., the system will protect and stop output. |

|

if the main power supply fails, the system operates according to the controlled slope. |

|

if the rotation is blocked, the system will protect the motor. |

|

when the motor current exceeds the rated current of the motor, it will stop automatically. |

|

panel layout of power distribution cabinet: power indication, emergency stop, computer touch screen, button switch. |

|

cooling mode of distribution cabinet: air conditioning cooling. |

|

power distribution and supply: three-phase five wire (a, B, C, N, PE), ac380v/220v. |

|

Schneider is used for contactors, air switches, circuit breakers, etc. |

|

intermediate relay: Schneider brand. |

Control Panel

|

Standard type |

|

Computer display temperature and vacuum degree |

|

The computer displays the speed, process step, operation status, monitoring, etc |

|

Equipment operation mode: Schneider brand button operation |

|

One emergency stop button |

|

High and low speed dispersion speed knob |

|

Power indication, manual / automatic, lifting, pressure relief, mixing and decentralized starting and speed regulation, etc |

Safety Interlock System

|

Explaination |

|

Press the emergency stop switch, and the equipment will stop immediately without any operation. |

|

The dispersion motor can be started only after the can body rises to the position. When the can body rises, the mixing motor can rotate slowly for mixing |

|

When the mixing shaft rotates, the can body cannot fall. |

|

When the mixing barrel is not in place, the barrel cannot rise. |

|

It stops automatically after the can body rises and falls in place. |

|

The material barrel can be unlocked only after the can body is lowered in place. |

|

There is an alarm when the can body rises and falls. |

|

When the motor current exceeds the value of the protection range, it will stop automatically. |

|

After the can body rises in place, it is equipped with a safety bolt to prevent the can body from falling abnormally after rising to the high position during maintenance. |

Accompanying Spare Parts

|

Name |

Specifications |

Texture of material |

Quantity |

Remarks |

|

Ladder shaped sealing strip of kettle cover |

10×8,L=3700 |

silica gel |

1 |

|

Attached Equipment Drawing

Structure diagram of guide circulating eddy current cooling at the side and bottom of charging cylinder

Transmission and sealing structure diagram

Technical configuration of 650L slurry transfer mixing drum

|

Can body size (mm) |

Φ 1100*850mm

|

|

(inner diameter x inner height) |

807L |

|

Design volume (L) |

Inner barrel -0.098mpa, jacket 0.8MPa |

|

Design pressure |

1 set of shaft mechanical seal and 2 fluororubber skeleton oil seals |

|

(Mpa) |

SUS304 is in contact with the material, jacket: 304, bottom material: 304 stainless steel +q235-b |

|

Seal as |

Inner cylinder δ 10mm (measured thickness after processing), jacket δ 5mm |

|

Main material |

Water cooling |

|

Can body thickness (mm) |

ball valve |

|

Temperature regulation form |

Φ 1 120mm sight hole, 1 vacuum gauge, 1 vent (with silencer), 1 vacuum hole |

|

Discharging form |

Mixing motor 3KW, one KONE reducer, rotating speed: 0-50rpm. Variable frequency speed control. |

Product Image