- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel, Villa, Apartment, Office Building, Hospital, School, Mall, Leisure Facilities, Supermarket, Warehouse, Workshop

-

Place of Origin:

-

China

-

Brand Name:

-

Montary

-

Model Number:

-

NAT-059

-

Product name:

-

Kitchen Countertop

-

Material:

-

Natural Marble

-

Color:

-

As Picture

-

Thickness:

-

18mm

-

Size:

-

Customer's Request

-

Surface Finishing:

-

Polished

Quick Details

-

Warranty:

-

3 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Hotel, Villa, Apartment, Office Building, Hospital, School, Mall, Leisure Facilities, Supermarket, Warehouse, Workshop

-

Place of Origin:

-

China

-

Brand Name:

-

Montary

-

Model Number:

-

NAT-059

-

Product name:

-

Kitchen Countertop

-

Material:

-

Natural Marble

-

Color:

-

As Picture

-

Thickness:

-

18mm

-

Size:

-

Customer's Request

-

Surface Finishing:

-

Polished

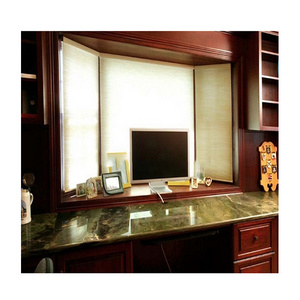

Products Description :

1. Brand Name: Montary

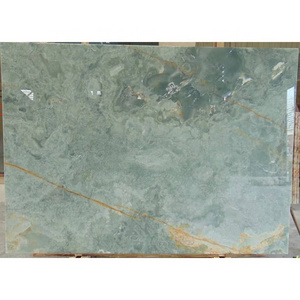

2. Material:Natural Marble

3. Place of Original: Yunfu ,Guangdong Province, China

4. Color: Optional as per you liked

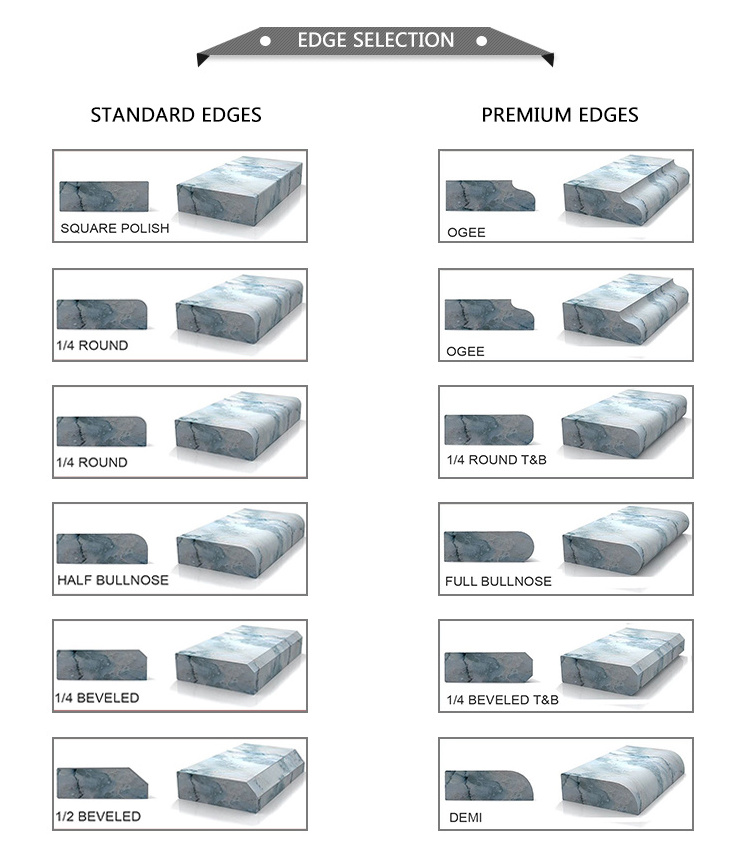

5. Countertop Edging : Flat Edge / Eased Edge / Additional Edge / Ogee / Waterfall, etc

6. Surface Finish: Polished / Honed finish, or according to the client demands.

7. Applications: Kitchen, Furniture etc

8. Supply Ability: 50000sets/month

9. Delivery Time: within 15 days after the order confirmed

Quality Assurance:

1. More than 10 years stone countertops/vanity tops manufacturing experience, stable color and quality control

2. full set of automatic countertops processing machine like infrared ray bridge cutting ,water jet machine ,edge polished machine ,45 degree cutting , edge cutting machine etc

3. most of the countertops worker already worked for more than 5 years ,some is 10 years ,can handles any design and special project order

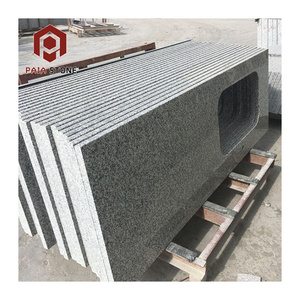

Production Flow for Countertop:

|

Step 1 |

Cutting (Infrared Bridge Cutting Machine) |

|

Step 2 |

Cutout (Water Jet Cutting Machine) |

|

Step 3 |

45 degree Cutting (45 degree Cutting Machine) |

|

Step 4 |

Polishing (Manual Polishing ) |

|

Step 5 |

Chamfer (Manual Beveling ) |

|

Step 6 |

Clean and Inspect (Manual Check) |

|

Step 7 |

Packing (by wooden crated) |