- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

non

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AOC

-

Model Number:

-

P50-952

-

Product name:

-

Unsaturated Polyester Resin

-

Application:

-

boat

-

Color:

-

Clear Viscous Liquid

-

Solid Content:

-

59-66%

-

Gel time (25℃-35℃):

-

18-29mins

-

Viscosity (23℃m ):

-

400-500mPa.s

-

Acide value:

-

20-27mgKOH/g

-

Process:

-

Hand lay-up

-

Package:

-

220 Kg/barrel

-

Chemical name:

-

Orthophthalic

Quick Details

-

CAS No.:

-

26123-45-5

-

Other Names:

-

unsaturated polyester resin

-

MF:

-

non

-

EINECS No.:

-

non

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AOC

-

Model Number:

-

P50-952

-

Product name:

-

Unsaturated Polyester Resin

-

Application:

-

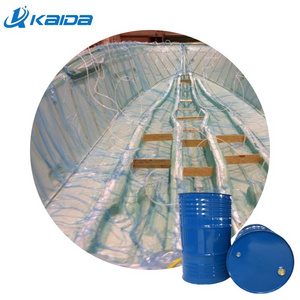

boat

-

Color:

-

Clear Viscous Liquid

-

Solid Content:

-

59-66%

-

Gel time (25℃-35℃):

-

18-29mins

-

Viscosity (23℃m ):

-

400-500mPa.s

-

Acide value:

-

20-27mgKOH/g

-

Process:

-

Hand lay-up

-

Package:

-

220 Kg/barrel

-

Chemical name:

-

Orthophthalic

Product Description

CHEMICAL/PHYSICAL NATURE

P 50-952 is an unsaturated polyester resin based on orthophthalic acid and standard glycols, dissolved in styrene.

P 50-952 has a low viscosity and a high reactivity.

MAJOR APPLICATIONS/PRINCIPAL PROPERTIES

P 50-952 is suitable for a wide range of applications. It is widely used for glass-fibre reinforced plastic, which is processed by hand lay-up. The products have good mechanical properties.

P 50-952 has certified by China Classification Society (CCS), especially for marine.

Specification

|

Property

|

Value

|

Unit

|

TM

|

|

Tensile strength

|

75

|

Mpa

|

ISO 527-2

|

|

Tensile E-modulus

|

3500

|

Mpa

|

ISO 527-2

|

|

Elongation at break

|

3

|

%

|

ISO 527-2

|

|

Flexural strength

|

125

|

MPa

|

ISO 178

|

|

Flexural E-modulus

|

3600

|

MPa

|

ISO 178

|

|

Impact res.-unnotched

|

15

|

KJ/m2

|

ISO 179

|

|

HDT

|

80

|

℃

|

ISO 75A

|

|

Hardness

|

>40

|

Barcol

|

-

|

CURING CONDITIONS

Cure for 24 hours at R.T. Post cure for 24 hours at 80

℃

.

TESTING CONDITIONS

Temperature: 23±2oC; relative moisture: 50±5%.

REMARKS

25oC 100g resin with 1.5g Butanox M50 (AKZO-Nobel) and 1.0g NL 49P (AKZO-Nobel)

Hand layup molding process, also known as contact molding, is the earliest and most widely used molding method in the production of resin based composite materials. Hand layup molding process is a molding method that mainly involves manual operation and less use of mechanical equipment. It uses unsaturated polyester resin or epoxy resin as the matrix material to bond reinforcement materials together. Although the hand layup molding operation is simple, it requires high operational skills from operators. It requires operators to have a serious work attitude, proficient operating skills, and rich practical experience. A comprehensive understanding of product structure, material performance, mold surface treatment, gel coat quality, glue content control, reduction and placement of reinforcing materials, uniformity of product thickness, and various factors affecting product quality is required.

Packing & Delivery

Hot Searches