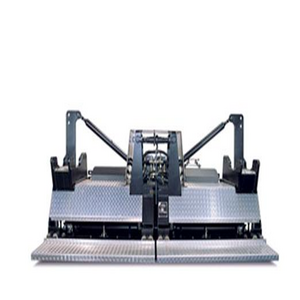

Picture this: your heavy machinery is tearing up asphalt roads and pavements, leaving a trail of costly damages in its wake.

It’s a nightmare scenario for any construction professional. But what if we told you there’s a simple solution to protect those

precious surfaces?

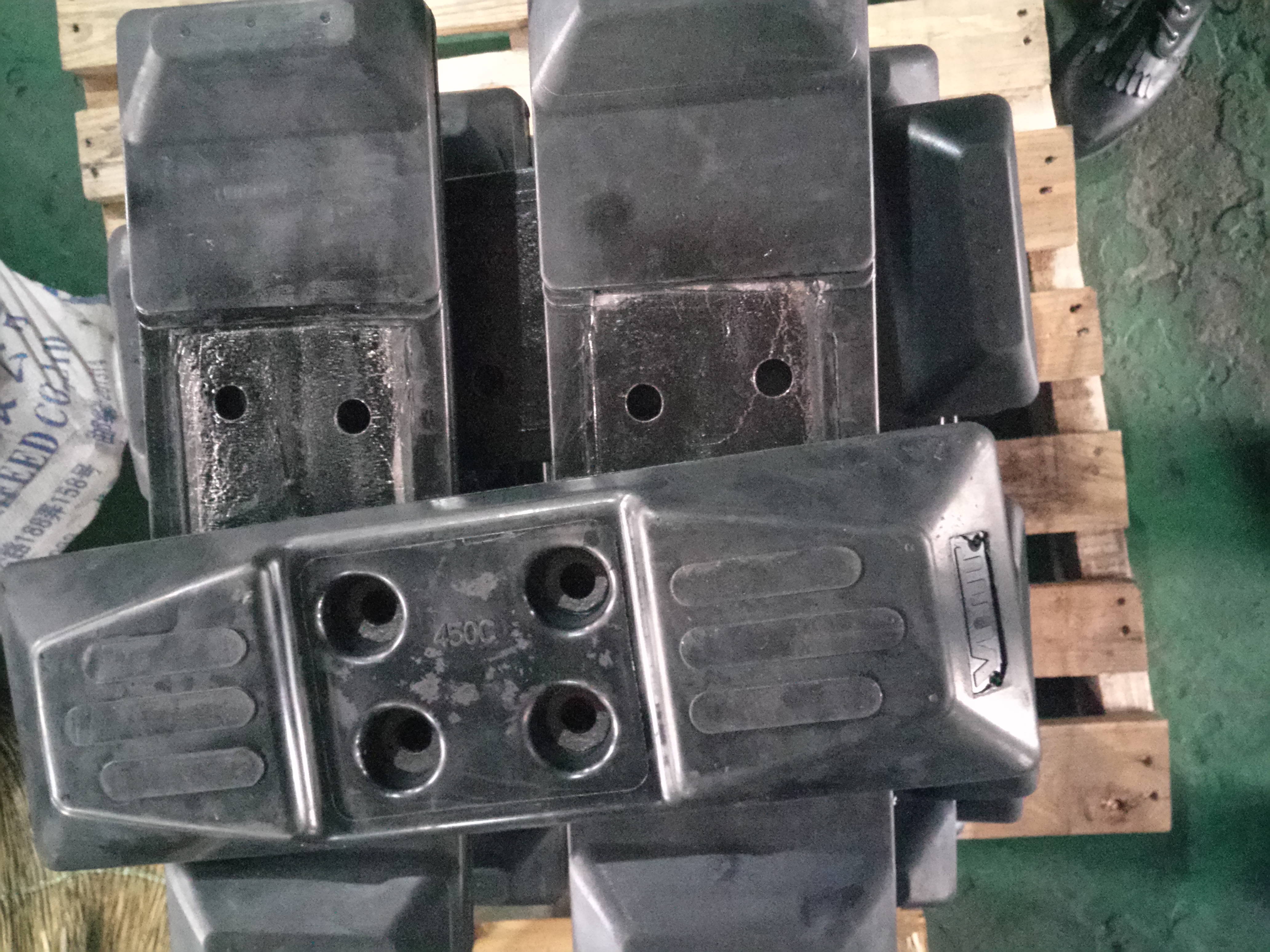

Meet our premium rubber pads – GQRT.

Designed and produced with durability and ease of fitting in mind, these rubber pads aren’t just any ordinary accessories. They’re

manufactured from top-notch, abrasion-resistant rubber using cutting-edge equipment and advanced quality control processes.

Available in three versatile styles and an extensive range of sizes, GQRT rubber pads will have your machinery gliding

smoothly across finished surfaces like a figure skater on ice.

- Product Details

- {{item.text}}

Quick Details

-

Length:

-

450mm

-

Width:

-

145mm

-

Height:

-

55mm

-

Pitch:

-

154mm

-

Bolt:

-

M14*50

-

Distance of two holes:

-

89mm

-

Weight:

-

7.414kg/pc

-

MOQ:

-

100pcs

-

Apply to:

-

Volvo, Wirtgen, Vogele, Dynapac, Bomag, Marini, Bitelli, XCMG etc.

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

GQRT

-

Material:

-

Rubber and Steel

-

Length:

-

450mm

-

Width:

-

145mm

-

Height:

-

55mm

-

Pitch:

-

154mm

-

Bolt:

-

M14*50

-

Distance of two holes:

-

89mm

-

Weight:

-

7.414kg/pc

-

MOQ:

-

100pcs

-

Apply to:

-

Volvo, Wirtgen, Vogele, Dynapac, Bomag, Marini, Bitelli, XCMG etc.

Product Description

RUBBER TRACK PADS

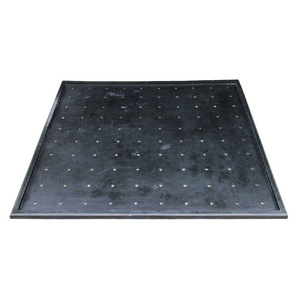

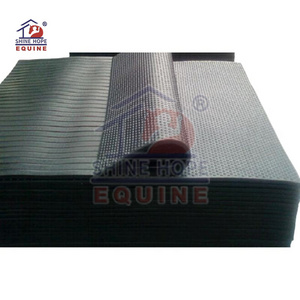

GQRT Rubber Pads are engineered to fit most triple grouser steel pads or chains, and consist of a thick rubber pad bonded to a steel core.

Some features and benefits of Kaixu's Rubber Pads include:

• Protection of Road Surfaces • Easy Installed/Removed On Site • Reduction in Overall Downtime • Superior Stability in Wet Conditions • Decreased Operator Noise and Vibration

Available pad styles include Bolt-On, Clip-On, Chain-On (Roadliner).

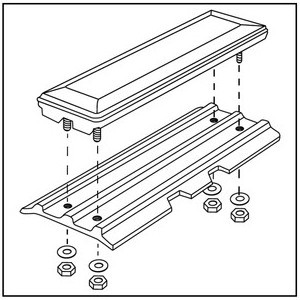

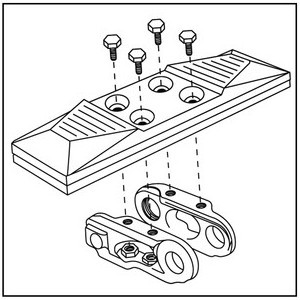

The Bolt-On pads work if your steel pads have pre-drilled holes.

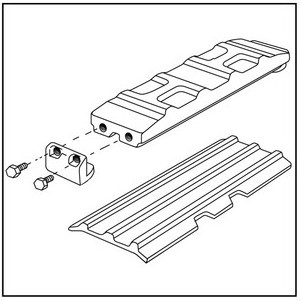

The Clip-On pads use clips that wrap around the grouser pad and work with most styles of triple grousers.

The Roadliner pads bolt directly to the chain so there is no triple-grouser shoe involved.

GQRT rubber pads come in many different widths, from

200mm

to

900mm

. We stock most popular sizes and are ready to ship the same day you complete your order!

Transform your construction machinery with GQRT rubber pads.

The Proof is in the Durability

But don’t just take our word for it – independent test results show that Kaixu rubber pads are an impressive 52% more

durable than standard-quality rubber pads. No wonder several of the largest global excavator OEMs have chosen Kaixu as their go-to rubber pad.

Choose from Bolt-on, Direct-to-Chain or Roadliner Pads

We understand that not all machinery is created equal, so we offer various pad styles to suit your specific needs. Whether you’re

a fan of the tried-and-true Bolt-on pads, prefer the sleek Direct-to-Chain or Roadliner pads, or want to try our innovative quick-fit clip-on pads that can be fitted in half the time of conventional pads, we’ve got you covered. And the cherry on top?

These quick-fit clip-on pads help minimize labor costs and maximize uptime so you can return to work quickly.

durable than standard-quality rubber pads. No wonder several of the largest global excavator OEMs have chosen Kaixu as their go-to rubber pad.

Choose from Bolt-on, Direct-to-Chain or Roadliner Pads

We understand that not all machinery is created equal, so we offer various pad styles to suit your specific needs. Whether you’re

a fan of the tried-and-true Bolt-on pads, prefer the sleek Direct-to-Chain or Roadliner pads, or want to try our innovative quick-fit clip-on pads that can be fitted in half the time of conventional pads, we’ve got you covered. And the cherry on top?

These quick-fit clip-on pads help minimize labor costs and maximize uptime so you can return to work quickly.

Roadliner Style

4T to 26T

The GQRT Roadliner Pad is a chunky one-piece vulcanised pad which bolts directly on to the steel track chain.

The strong internal steel core is specially treated to ensure excellent bonding during the vulcanisation process and is fully encased in rubber to prevent any possibility of damage to finished surfaces. The abrasion-resistant, anti-chunking rubber compound ensures excellent durability and consistent wearability.

Ideal for machines from 4T to 26T for a wide variety of applications including rail infrastructure work, individual pads can be

replaced quickly and inexpensively as required.

The GQRT Roadliner Pad is a chunky one-piece vulcanised pad which bolts directly on to the steel track chain.

The strong internal steel core is specially treated to ensure excellent bonding during the vulcanisation process and is fully encased in rubber to prevent any possibility of damage to finished surfaces. The abrasion-resistant, anti-chunking rubber compound ensures excellent durability and consistent wearability.

Ideal for machines from 4T to 26T for a wide variety of applications including rail infrastructure work, individual pads can be

replaced quickly and inexpensively as required.

|

Chain-on Type

|

|

|

|

|

|

|

|

|||||||

|

Model

|

Pitch

|

A*B*C

|

Bolt

|

D

|

E

|

F

|

Note

|

|||||||

|

180CA

|

125

|

185*145*45

|

M10*35

|

80

|

80

|

53

|

A

|

|||||||

|

200CA

|

101

|

205*109*40

|

M10*35

|

65

|

0

|

0

|

B

|

|||||||

|

200CB

|

101

|

205*109*40

|

M8*35

|

48

|

48

|

35

|

A

|

|||||||

|

225CA

|

125

|

230*145*45

|

M10*35

|

80

|

80

|

53

|

B

|

|||||||

|

225CB

|

140

|

230*163*50

|

M12*40

|

86

|

86

|

52

|

B

|

|||||||

|

250CA

|

125

|

255*145*45

|

M10*35

|

80

|

80

|

53

|

B

|

|||||||

|

260CA

|

135

|

265*154*50

|

M12*40

|

104

|

80

|

46

|

B

|

|||||||

|

260CB

|

135

|

265*154*50

|

M12*40

|

99

|

72

|

43.4

|

B

|

|||||||

|

260CC

|

140

|

265*163*50

|

M12*40

|

86

|

86

|

52

|

B

|

|||||||

|

280CA

|

135

|

285*154*50

|

M12*40

|

106

|

76

|

46

|

B

|

|||||||

|

280CB

|

135

|

285*154*50

|

M12*40

|

99

|

72

|

43.4

|

B

|

|||||||

|

300CA

|

156

|

305*165*50

|

M12*45

|

88.9

|

88.9

|

57.15

|

B

|

|||||||

|

300CB

|

156

|

305*165*50

|

M12*40

|

88.9

|

88.9

|

57.15

|

B

|

|||||||

|

300CC

|

125

|

305*145*40

|

M10*35

|

80

|

80

|

53

|

B

|

|||||||

|

300CD

|

125

|

305*145*45

|

M10*35

|

80

|

80

|

53

|

B

|

|||||||

|

300CE

|

140

|

305*163*50

|

M12*40

|

86

|

86

|

52

|

B

|

|||||||

|

300CF

|

154

|

305*165*50

|

M14*49

|

89

|

73

|

57

|

B

|

|||||||

|

300CG

|

135

|

305*154*50

|

M12*40

|

99

|

72

|

43.4

|

B

|

|||||||

|

300CH

|

101

|

305*95*45

|

M12*45

|

144

|

116

|

22

|

B

|

|||||||

|

320CA

|

156

|

325*165*57

|

M14*49

|

104.8

|

88.9

|

54.8

|

B

|

|||||||

|

320CB

|

156

|

325*165*57

|

M14*49

|

104.8

|

88.9

|

54.8

|

B

|

|||||||

|

320CC

|

156

|

325*165*50

|

M12*40

|

88.9

|

88.9

|

57.15

|

B

|

|||||||

|

320CD

|

156

|

325*165*50

|

M12*45

|

88.9

|

88.9

|

57.15

|

B

|

|||||||

|

350CA

|

171

|

355*190*60

|

M16*53

|

108

|

108

|

60.3

|

B

|

|||||||

|

350CB

|

125

|

355*145*45

|

M10*35

|

80

|

80

|

53

|

B

|

|||||||

|

350CC

|

156

|

355*165*50

|

M12*45

|

88.9

|

88.9

|

57.15

|

B

|

|||||||

|

380CA

|

|

380*42*40

|

M8*35

|

|

|

|

A

|

|||||||

|

400CA

|

135

|

400*125*56

|

M12*40

|

94

|

64

|

46

|

A

|

|||||||

|

400CB

|

135

|

400*125*56

|

M12*40

|

104

|

80

|

46

|

A

|

|||||||

|

400CC

|

135

|

400*125*56

|

M12*40

|

99

|

72

|

43.4

|

A

|

|||||||

|

400CD

|

140

|

400*125*56

|

M12*40

|

86

|

86

|

52

|

A

|

|||||||

|

400CE

|

135

|

400*125*56

|

M12*40

|

110

|

80

|

46

|

A

|

|||||||

|

400CF

|

140

|

400*125*56

|

M12*40

|

80

|

80

|

52

|

A

|

|||||||

|

400CG

|

125

|

405*145*45

|

M10*35

|

80

|

80

|

53

|

B

|

|||||||

|

400CH

|

135

|

400*125*56

|

M12*40

|

101

|

83

|

45

|

A

|

|||||||

|

400CI

|

135

|

400*125*56

|

M12*40

|

98.4

|

74.4

|

46

|

A

|

|||||||

|

400CJ

|

156

|

405*165*50

|

M12*40

|

88.9

|

88.9

|

57.15

|

B

|

|||||||

|

400CK

|

135

|

400*125*56

|

M12*40

|

90

|

66

|

46

|

A

|

|||||||

|

400CL

|

140

|

405*163*50

|

M12*40

|

86

|

86

|

52

|

B

|

|||||||

|

400CM

|

156

|

405*165*50

|

M12*45

|

88.9

|

88.9

|

57.15

|

A

|

|||||||

|

400CN

|

154

|

405*145*60

|

M14*49

|

99

|

99

|

56

|

B

|

|||||||

|

400CO

|

135

|

400*125*56

|

M12*40

|

94

|

64

|

46

|

B

|

|||||||

|

400CP

|

135

|

400*125*56

|

M12*40

|

104

|

80

|

46

|

B

|

|||||||

|

400CQ

|

135

|

400*125*56

|

M12*40

|

99

|

72

|

43.4

|

B

|

|||||||

|

450CA

|

154

|

450*146*56

|

M14*49

|

90

|

90

|

55

|

A

|

|||||||

|

450CB

|

154

|

450*146*56

|

M14*49

|

89

|

73

|

57

|

A

|

|||||||

|

450CC

|

135

|

450*125*56

|

M12*40

|

110

|

80

|

46

|

A

|

|||||||

|

450CD

|

140

|

450*125*56

|

M12*40

|

86

|

86

|

52

|

A

|

|||||||

|

450CE

|

135

|

450*125*56

|

M12*40

|

99

|

72

|

43.4

|

A

|

|||||||

|

450CF

|

154

|

450*146*56

|

M14*49

|

90

|

90

|

46.3

|

A

|

|||||||

|

450CG

|

140

|

450*125*56

|

M12*40

|

83

|

83

|

52

|

A

|

|||||||

|

450CH

|

154

|

450*146*56

|

M14*49

|

73

|

73

|

57

|

A

|

|||||||

|

450CI

|

154

|

450*146*56

|

M14*49

|

112.4

|

82.4

|

54

|

A

|

|||||||

|

450CJ

|

154

|

450*146*56

|

M14*49

|

89

|

89

|

57

|

A

|

|||||||

|

450CK

|

154

|

450*146*56

|

M14*49

|

99

|

99

|

56

|

A

|

|||||||

|

450CL

|

135

|

450*125*56

|

M12*40

|

106

|

76

|

46

|

A

|

|||||||

|

450CM

|

135

|

450*125*56

|

M12*40

|

112.4

|

82.4

|

57

|

A

|

|||||||

|

450CN

|

154

|

450*146*56

|

M14*49

|

89

|

73

|

57

|

B

|

|||||||

|

450CO

|

140

|

450*125*56

|

M14*49

|

86

|

86

|

52

|

A

|

|||||||

|

500CA

|

135

|

500*125*56

|

M12*40

|

110

|

80

|

46

|

A

|

|||||||

|

500CB

|

175

|

500*162*66

|

M16*53

|

102.4

|

86.4

|

57

|

A

|

|||||||

|

500CC

|

171

|

500*162*66

|

M16*53

|

108

|

108

|

60.3

|

A

|

|||||||

|

500CE

|

190

|

500*178*76

|

M20*57

|

155.6

|

119.6

|

69

|

A

|

|||||||

|

500CF

|

135

|

500*125*56

|

M12*40

|

104

|

80

|

46

|

A

|

|||||||

|

500CG

|

154

|

500*146*56

|

M14*49

|

89

|

89

|

57

|

A

|

|||||||

|

500CH

|

175

|

500*162*66

|

M16*53

|

144.5

|

125.4

|

58.7

|

A

|

|||||||

|

500CI

|

175

|

500*162*66

|

M16*53

|

145.2

|

125

|

58.4

|

A

|

|||||||

|

500CJ

|

154

|

500*146*56

|

M14*49

|

90

|

90

|

55

|

A

|

|||||||

|

500CK

|

156

|

500*146*56

|

M14*49

|

104.8

|

88.9

|

54.8

|

A

|

|||||||

|

500CL

|

156

|

500*146*56

|

M12*40

|

88.9

|

88.9

|

57.1

|

A

|

|||||||

|

500CM

|

160

|

500*146*56

|

M14*49

|

99

|

99

|

56

|

A

|

|||||||

|

500CN

|

140

|

500*125*56

|

M12*40

|

86

|

86

|

52

|

A

|

|||||||

|

500CO

|

171

|

500*162*66

|

M16*53

|

108

|

108

|

60.3

|

B

|

|||||||

|

500CP

|

140

|

500*145*56

|

M12*40

|

86

|

86

|

52

|

A

|

|||||||

|

500CQ

|

175

|

500*162*66

|

M18*53

|

158.4

|

122.4

|

57

|

A

|

|||||||

|

600CA

|

135

|

600*125*56

|

M12*40

|

110

|

80

|

46

|

A

|

|||||||

|

600CB

|

154

|

600*146*56

|

M14*49

|

89

|

73

|

57

|

A

|

|||||||

|

600CC

|

171

|

600*162*66

|

M16*53

|

108

|

108

|

60.3

|

A

|

|||||||

|

600CD

|

190

|

600*178*76

|

M20*57

|

155.6

|

119.6

|

69

|

A

|

|||||||

|

600CE

|

190

|

600*178*76

|

M20*57

|

160.4

|

124.4

|

62

|

A

|

|||||||

|

600CF

|

190

|

600*178*76

|

M18*57

|

160.4

|

124.4

|

62

|

A

|

|||||||

|

600CG

|

175

|

600*162*66

|

M16*53

|

144.5

|

125.4

|

58.7

|

A

|

|||||||

|

600CH

|

156

|

600*146*56

|

M12*40

|

88.9

|

88.9

|

57.1

|

A

|

|||||||

|

600CI

|

156

|

600*146*56

|

M14*49

|

104.8

|

88.9

|

54.8

|

A

|

|||||||

|

600CJ

|

175

|

600*162*66

|

M16*53

|

102.4

|

86.4

|

57

|

A

|

|||||||

|

600CK

|

140

|

600*125*56

|

M12*40

|

86

|

86

|

52

|

A

|

|||||||

|

600CL

|

135

|

600*125*56

|

M12*40

|

104

|

80

|

46

|

A

|

|||||||

|

600CM

|

154

|

600*146*56

|

M14*49

|

90

|

90

|

55

|

A

|

|||||||

|

600CN

|

190

|

600*178*76

|

M20*57

|

155.6

|

119.6

|

69

|

B

|

|||||||

|

600CO

|

190

|

600*178*76

|

M20*57

|

160.4

|

124.4

|

62

|

B

|

|||||||

|

700CA

|

171

|

700*162*66

|

M16*53

|

108

|

108

|

60.3

|

A

|

|||||||

|

700CB

|

156

|

700*146*56

|

M12*40

|

88.9

|

88.9

|

57.1

|

A

|

|||||||

|

700CC

|

156

|

700*146*56

|

M14*49

|

104.8

|

88.9

|

54.8

|

A

|

|||||||

Our Rubber Pads Are The Operator's First Choice...

1. Large Stock Availability

Our finely-tuned stock control program coupled with a highly organised warehousing and logistics system allows Kaixu to have the rubber pads you need available when you need them, minimising machine downtime.

2. Quality Approved

All of our GQRT rubber pads are manufactured in IS0 9001 approved production facilities with rigorous quality control procedures.

3. Highly Durable

Independent test results show GQRT rubber pads to be 52% more durable than standard quality rubber pads.

4. Fast Delivery

We can get your orders delivered to you when and where you need them.

Key Advantages of Rubber Track Pads

* As an essential part of your undercarriage system, the quality retention of our rubber pads is very high.

* Long-term cost-effective with our innovative Formula E foundation technology rubber pads.

* Consistent wearability and outstanding durability even on steel track chain.

* GQRT rubber tracks are specified for use on different surfaces.

* Our bolt-on rubber pads come in easy mounting styles, making it easy to replace a pad.

* Long-term cost-effective with our innovative Formula E foundation technology rubber pads.

* Consistent wearability and outstanding durability even on steel track chain.

* GQRT rubber tracks are specified for use on different surfaces.

* Our bolt-on rubber pads come in easy mounting styles, making it easy to replace a pad.

Whether it’s a long hard construction application using or naturally, ballast material such as rail maintenance, this rubber pad is built to provide a solid and secure foundation for the machine and its components to stand on without damaging the surface.

Features of GQRT Rubber Pad

Longer Service Life Span: Formula E Technology

GQRT applies Formula E, one of our proprietary core technologies, to our rubber track pads, slowing down the rubber's aging

(fatigue) speed. This technology results in longer service life and maintains excellent properties capabilities, especially for

intense extracting construction projects.

(fatigue) speed. This technology results in longer service life and maintains excellent properties capabilities, especially for

intense extracting construction projects.

Special Rubber Compound: Pavers, Excavators & Cold Planer

GQRT uses a specially developed rubber formula for each road construction application, delivering excellent capabilities in your operating environment to support your success in every project.

Superior Moving Experience: Patent Chamfer Edge Design

GQRT optimizes its track pad chamfer edge with a meticulous design, advancing the quality and steering agility to overcome rugged road surfaces. The chamfer feature helps excavators avoid unnecessary wear and tear and enables them to handle the most complex construction projects. Additionally, our chamfer design offers on-site protection against close contact.

Extreme Durable: Patent Support Frame and Built-in Steel plate

Impossibly Durable

GQRTrubber track pads, as a premier choice for the excavator undercarriage parts, provide extreme durability, a patented support frame, and a built-in steel plate—all engineered to substantially increase the strength of track pads and prevent any deformation.

GQRTrubber track pads, as a premier choice for the excavator undercarriage parts, provide extreme durability, a patented support frame, and a built-in steel plate—all engineered to substantially increase the strength of track pads and prevent any deformation.

Cost-Efficiency Solution: Bolt-on Excavator Track Pads

GQRT first invented bolt-on track pads, providing a more straightforward installation and cost-efficient solution. Our bolt-on track

pads for excavators provide stability for operators who work on railroad construction or other rugged road surfaces.

pads for excavators provide stability for operators who work on railroad construction or other rugged road surfaces.

A Perfect Fit when Bolt-on Pads are Incompatible: Chain-on Track Pads

Chain-on track pads, another popular track pad type, include the rubber part molded together with the steel plate. These are optimal when bolt-on pads are incompatible with your excavators. We also provide 500mm chain-on excavator rubber track pads for larger machines, including CatⓇ, Volvo, Hitachi, and other brand excavators.

Please get in touch with us for immediate assistance if you cannot find your machine/model in the Finder’s drop-down menus.

Applications

Hot Searches