- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customize

-

Current:

-

350A

-

Rated Capacity:

-

Depends

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

Customize

-

Use:

-

LPG gas cylinder welding purpose

-

Product name:

-

Circumferential Seam Welding Machine with Automatic Tracker

-

Application:

-

LPG gas cylinder welding

-

Feature:

-

Fully automatic with conveyor and chain

-

Welding Method:

-

MIG welding

-

Welding pass:

-

1 pass

-

System:

-

Double tracking system

-

Welding Speed:

-

60 seconds for one pass

-

Productivity:

-

350 cylinders per set per hour

-

Welding wire diameter:

-

1.2mm

-

Welding power:

-

Panasonic

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Turkey, United States, Viet Nam, Philippines, Pakistan, India, Thailand, Malaysia, Kenya, Bangladesh, South Africa, Nigeria

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LTM

-

Weight (KG):

-

4 tons per set

-

Voltage:

-

Customize

-

Current:

-

350A

-

Rated Capacity:

-

Depends

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

Customize

-

Use:

-

LPG gas cylinder welding purpose

-

Product name:

-

Circumferential Seam Welding Machine with Automatic Tracker

-

Application:

-

LPG gas cylinder welding

-

Feature:

-

Fully automatic with conveyor and chain

-

Welding Method:

-

MIG welding

-

Welding pass:

-

1 pass

-

System:

-

Double tracking system

-

Welding Speed:

-

60 seconds for one pass

-

Productivity:

-

350 cylinders per set per hour

-

Welding wire diameter:

-

1.2mm

-

Welding power:

-

Panasonic

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Turkey, United States, Viet Nam, Philippines, Pakistan, India, Thailand, Malaysia, Kenya, Bangladesh, South Africa, Nigeria

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE

Circumferential Seam Welding Machine with Automatic Laser and video Tracker

Product Description

We supply the complete welding solutions for LPG cylinder, such as socket welding machine, handle/collar welding machine, base ring welding machine, longitudinal welding machine single/double circumference welding machine et cetera.

|

Comparision between MIG and SAW welding for LPG gas cylinder

|

|

|

||

|

2000 pcs cylinders/8 Hours

|

|

|

||

|

Description

|

MIG welding

|

Saw welding

|

||

|

Capacity

|

360 pcs/8hrs/set

|

240 pcs/8hrs/set

|

||

|

No. of welding machines

|

6

|

8

|

||

|

No. of welders

|

3

|

39

|

||

|

No of welding pass

|

one path

|

two paths

|

||

|

Power consumption

|

MIG saves 40% than SAW

|

|

||

|

Wire consumption

|

MIG saves 40% than SAW

|

|

||

|

Auto laser & video tracing device

|

MIG welder has auto laser & video tracing device, SAW welder does not

|

|

||

Machine Configuration

Consider different requirements, we prompt two machine configuration

Full auto & Semi auto

which could be selected by customers to fit for the budget.

Full autoamtic welding line feature

Full-auto welding machine includes socket welding, handle/collar welding, base ring welding, circumference welding, and all machines work automatically, the cylinder halves are conveyed by mechancial arm and chain, this system really saves much labor cost and improve the working efficiency apparently.

Full auto single head circumference welding

This machine is used for cylinder upper shell and lower shell welding, it adopts seam

vision tracking device, automatic imaging to tracking welding seam, welding the circumferential seam automatically, no need of manual intervention. It adopts Panasonic 500GS (special) high-speed pulse MIG welding source. Welding speed can reach to

1000mm/min. It adopts double internal cooling MIG torch, it is suitable for long time welding. It is equipped with Supercooler

automatic circulating cooling water tank to cooling the welding torch circularly.

vision tracking device, automatic imaging to tracking welding seam, welding the circumferential seam automatically, no need of manual intervention. It adopts Panasonic 500GS (special) high-speed pulse MIG welding source. Welding speed can reach to

1000mm/min. It adopts double internal cooling MIG torch, it is suitable for long time welding. It is equipped with Supercooler

automatic circulating cooling water tank to cooling the welding torch circularly.

Panasonic welding source/power

500A double water-cooling MIG welding torch

φ1.2mm solid core welding wire

Template full automatic welding line layout

Full automatic welding line detailed introduction

Full auto socket welding

This machine is used for upper cap socket welding and edge welding part polishing. Equip with Panasonic YD-350GL4 welder 1 set, water cooling welding torch 1 pcs, 8L automatic cycle water cooling tank 1 set. The main shaft motor is 0.75KW. Polishing motor is 1.5KW, equip with the grating security protection.

Equip with NO. 6 Hydraulic station, 1 set, vane pump, 5.5KW. Setting pressure: falling 4 MPa, rising 9 MPa.

Equip with NO. 6 Hydraulic station, 1 set, vane pump, 5.5KW. Setting pressure: falling 4 MPa, rising 9 MPa.

Full auto handle welding

T

his machine is used for upper cap hadnle welding. Equip with three sets welding torch, 3 welders finish at one time. Equip with

Panasonic YD-350GL4 welders 3 sets, welding torch 3 pieces. Main shaft motor is 0.4KW, with the grating security protection. Equip with No.7 hydraulic station, vane pump, 5.5KW. Setting pressure: pressing 4MPa, rising 9MPa.

Panasonic YD-350GL4 welders 3 sets, welding torch 3 pieces. Main shaft motor is 0.4KW, with the grating security protection. Equip with No.7 hydraulic station, vane pump, 5.5KW. Setting pressure: pressing 4MPa, rising 9MPa.

Full auto base ring welding

This machine is used for lower cap bottom base welding, equip with three welding torch, 6 welders could be finished at two times. Equip

with Panasonic YD-350GL4 welder 3 sets, welding torch 3 piece. Main shaft motor 0.4KW, with the grating security protection . Equip with No.3 hydraulic station, vane pump, 5.5KW, setting pressure: pressing 4MPa, rising 10MPa.

with Panasonic YD-350GL4 welder 3 sets, welding torch 3 piece. Main shaft motor 0.4KW, with the grating security protection . Equip with No.3 hydraulic station, vane pump, 5.5KW, setting pressure: pressing 4MPa, rising 10MPa.

Semi auto welding machine feature

Semi auto welding machines adopt more operators for loading and unloading cylinder halves purpose, whereas this option is economy if the budget is tight.

Template semi auto welding machine layout

Semi auto welding machine detailed introduction

Semi auto socket welding machine

Motor power: 0.75KW

Air pressure: 0.4 - 0.8 MPa

Welding torch adjusting range:

X: 0-100mm

Y: 0-50mm

Welding torch angle adjusting range:±45°

Speed: 60S/pcs

Machine weight: 600KG

Machine dimension: 900x500x2150mm

Semi auto handle & base ring welding machine

Motor power: 0.75KW

Air pressure: 0.4 - 0.8 MPa

Welding torch adjusting range:

X: 0-100mm

Y: 0-50mm

Welding torch angle adjusting range:±45°

Speed: 60S/pcs Machine weight: 600KG Machine dimension: 900x500x2150mm

Additional machine for big cylinder

Fully automatic longitudinal welding machine

This machine is used for longitudinal seam welding machine, using button+pedal button+touch screen to

control, very convenient/ Equip with Panasonic YD-350GL4 welder 1 set,300A TIG welding torch 1 piece, laser chiller 1 set

control, very convenient/ Equip with Panasonic YD-350GL4 welder 1 set,300A TIG welding torch 1 piece, laser chiller 1 set

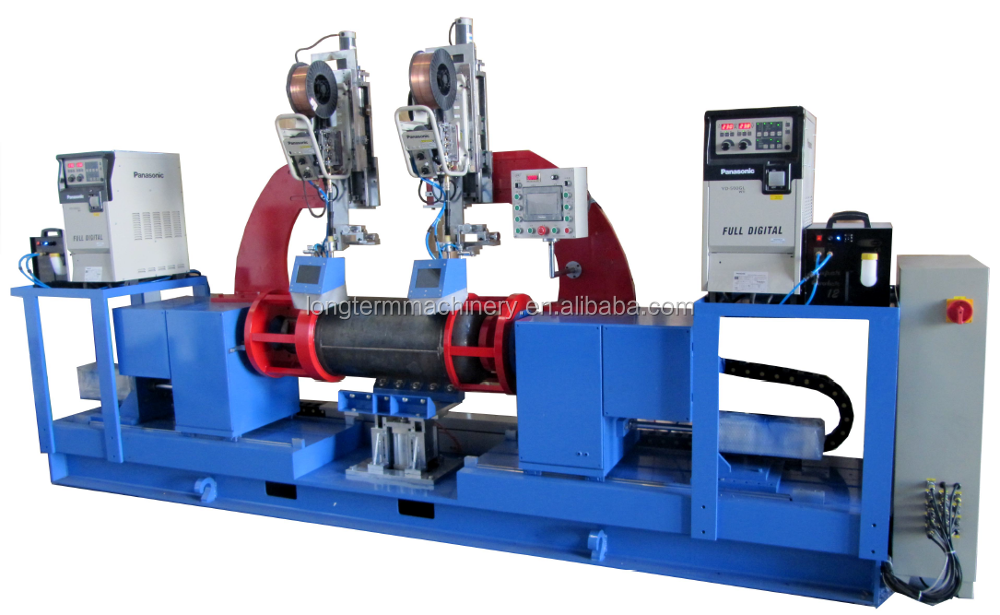

Fully autoamtic double heads circumference welding machine

The machine is used for circumferential welding of upper and lower cap, equip with welder vision tracking system, finish the circumferential welding automatically, full automatic and no operator, each set equips with Panasonic

YD-500GS high speed welder 2 set, water cooling welding torch 2 piece, 8L circle cooling tank 2 piece. Equip with welder vision tracking system 2 set. The electrical control system uses Mitsubishi PLC control unit, pro-face color touch screen operation screen.

YD-500GS high speed welder 2 set, water cooling welding torch 2 piece, 8L circle cooling tank 2 piece. Equip with welder vision tracking system 2 set. The electrical control system uses Mitsubishi PLC control unit, pro-face color touch screen operation screen.

Detailed Images

With high quality welding technology guarantee, our LPG cylinder quality can be guaranteed, bellow attach some welding line details:

Longitudinal welding & Circumference welding

Base ring welding

Handle welding & Socket welding

After Sales Service

Timely & satisfied oversea installation service

We have rich experience for oversea installation and commissioning work, we always send the skilled engineers for assisting our clients to run the machine smoothly and quickly.

Our strong machining ability

Our hired employees are over 100 for different working process, such as milling lathe, punching machine, heat treatment, grinding machine, cause we make all machine parts by ourselves, we can ensure the parts quality by 100%.

Additionally, with strong manufacuting ability, we can delivery every order on time.

Company Introduction

Wuxi Longterm Machinery Technologies Co.,Ltd

Wuxi Longterm Machinery Technologies Co.,Ltd is the professional manufacturer of auto-welding equipment (MIG, TIG, MAG, PAW) and automatic welding system integration, as well as related equipment.Due to highly automatic, simple operation, welding strength and service life with the same stainless steel and plate, is widely used in aerospace, chemical industry, machinery, pressure vessels, fire extinguishers, water heater, enamel water tank, stainless steel products and other industries.

FAQ

In order to recommend you the proper machine, we'd like to get the below info from you:

- What's the cylinder size you want to produce?

- It's better to provide the cylinder drawing.

- What's the daily capacity you want to attain?

Hot Searches