- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Voltage:

-

380v, 50Hz/ Customized

-

Dimension(L*W*H):

-

1500*1050*1460mm

-

Weight:

-

520 KG

Quick Details

-

Type:

-

peanut sheller

-

Use:

-

peanut, groundnut

-

Production Capacity:

-

800-1000kg/h

-

Place of Origin:

-

China

-

Voltage:

-

380v, 50Hz/ Customized

-

Dimension(L*W*H):

-

1500*1050*1460mm

-

Weight:

-

520 KG

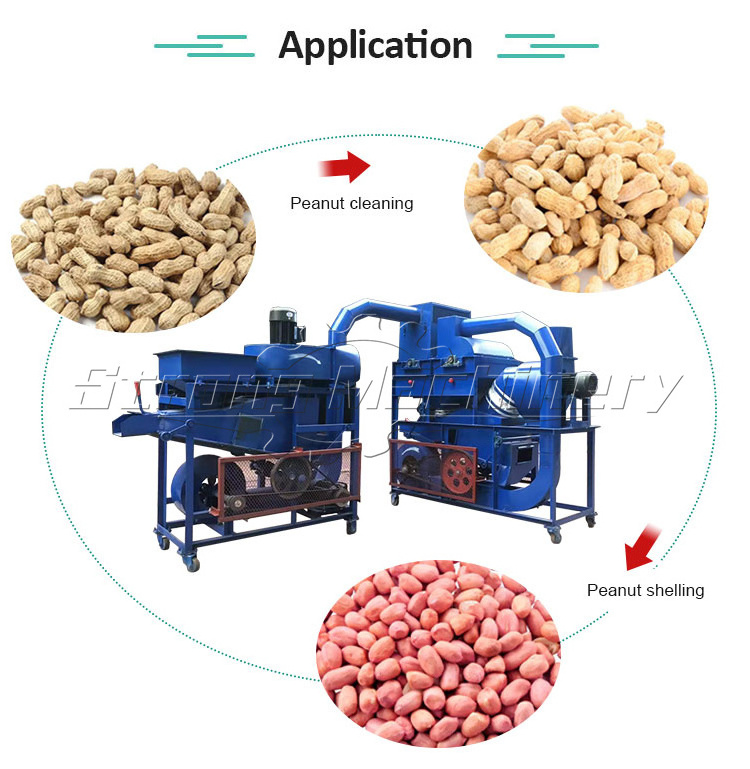

Products Description

The peanut huller machine includes a stone removal part and a shelling part, which can effectively improve the efficiency of peanut shelling. The peanuts after shelling have a high integrity rate, low breakage rate, and stable working performance.

Products Parameters

|

Model

|

6BHX-1500

|

|

Capacity

|

800-1000kg/h

|

|

Shelling Rate (%)

|

≥99

|

|

Cleaning Rate (%)

|

≥99

|

|

Breakage Rate (%)

|

≤5

|

|

Loss Rate (%)

|

≤0.5

|

|

Humidity (%)

|

10

|

|

Shelling Motor

|

1.5KW+3KW

|

|

Cleaning Motor

|

2.2KW

|

|

Weight

|

520kg

|

|

size

|

1500*1050*1460mm

|

|

Packing size

|

7 CBM

|

Details Images

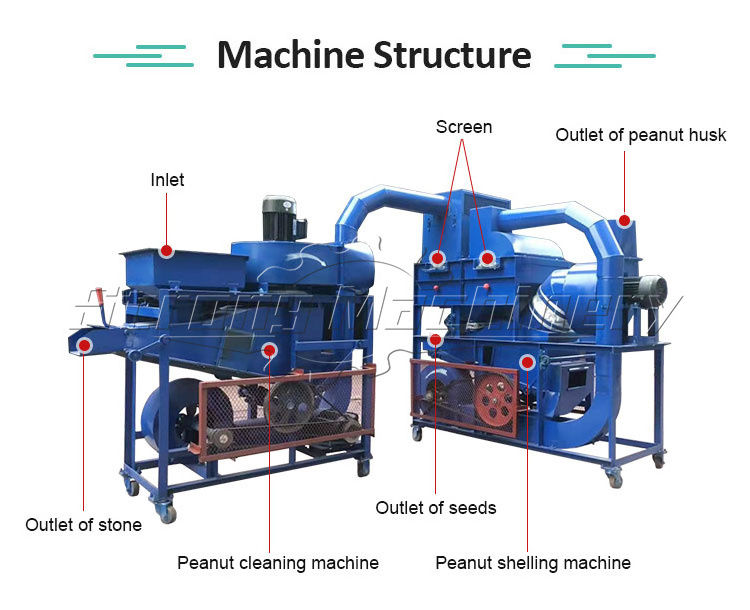

1. The peanut shelling machine consists of two basic components, the stone removal part and the shelling part, ensuring thorough cleaning and efficient shelling.

2. This peanut husker machine is equipped with an advanced stone removal system, which can effectively remove stones and other impurities in raw peanuts and prevent damage caused by foreign matter.

3. This groundnut huller machine uses a pneumatic conveying system to convey the cleaned peanuts from the stone removal part to the shelling part. This reduces manual processing and streamlines the entire processing workflow.

4. The shelling part adopts a unique double-roller mechanism, designed to skillfully open peanut shells while maintaining the integrity of the inner kernels. This ensures a high yield of whole peanut kernels and minimizes waste.

2. This peanut husker machine is equipped with an advanced stone removal system, which can effectively remove stones and other impurities in raw peanuts and prevent damage caused by foreign matter.

3. This groundnut huller machine uses a pneumatic conveying system to convey the cleaned peanuts from the stone removal part to the shelling part. This reduces manual processing and streamlines the entire processing workflow.

4. The shelling part adopts a unique double-roller mechanism, designed to skillfully open peanut shells while maintaining the integrity of the inner kernels. This ensures a high yield of whole peanut kernels and minimizes waste.

Product Packaging

Why Choose Us

Our company has been established for more than ten years and is a comprehensive entity enterprise specializing in machinery production, processing and sales. With a solid foundation built on years of experience, we have become a trustworthy brand in the industry.

We come to manufacture high-quality machinery to meet the ever-changing needs of our customers. From inquiry to delivery, we provide comprehensive solutions tailored to each client's unique needs. Our diverse range of products covers a wide range of sectors, ensuring we can meet a wide range of industry needs. Strict quality control measures are implemented at every stage of production to ensure that our machinery not only meets but exceeds industry standards. Our impact is rooted in local and extends globally.

Hot Searches