- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1480 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QINGHANG

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

30M*2M*2.5M

-

Power (kW):

-

200

-

Weight:

-

22000 KG

-

Cooling way:

-

spray, immersion

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

38:1

-

Screw diameter (mm):

-

90mm

-

Screw Speed (rpm):

-

1480 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QINGHANG

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

30M*2M*2.5M

-

Power (kW):

-

200

-

Weight:

-

22000 KG

-

Cooling way:

-

spray, immersion

-

Marketing Type:

-

Ordinary Product

product properties

Equipment list

|

MAIN EQUIPMENT

|

|

|

||

|

NO.

|

Description

|

Qty

|

||

|

1

|

Automatic feeding system

|

1 set

|

||

|

2

|

Single screw extruder

|

1 set

|

||

|

3

|

Co-extruder for marking line

|

1 set

|

||

|

4

|

Mould and die head and sizing sleeve

|

1 set

|

||

|

5

|

Vacuum water cooling tank

|

1 set

|

||

|

6

|

Spray water cooling tank

|

1 set

|

||

|

7

|

Traction machine

|

1 set

|

||

|

8

|

Chip free cutting machine

|

1 set

|

||

|

9

|

Automatic unloading rack

|

1 set

|

||

|

10

|

Winding machine

|

1 set

|

||

|

ACCESSORY EQUIPMENT(optional)

|

|

|

||

|

11

|

Resin high speed mixer and cooling mixer

|

1 set

|

||

|

12

|

Laser printing machine

|

1 set

|

||

|

13

|

Water cooling chilling machine

|

1 set

|

||

|

14

|

Crusher

|

1 set

|

||

|

15

|

Meter weight controller

|

1 set

|

||

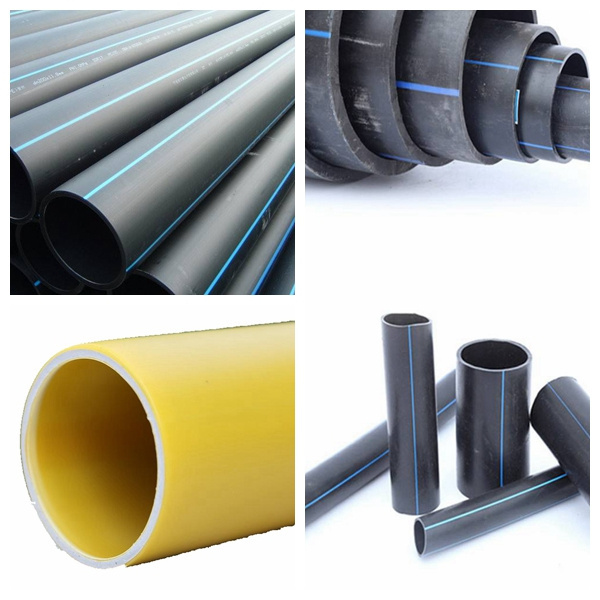

SAMPLE DISPLAY

PE PP PIPE PLASTIC EXTRUSION MACHINE

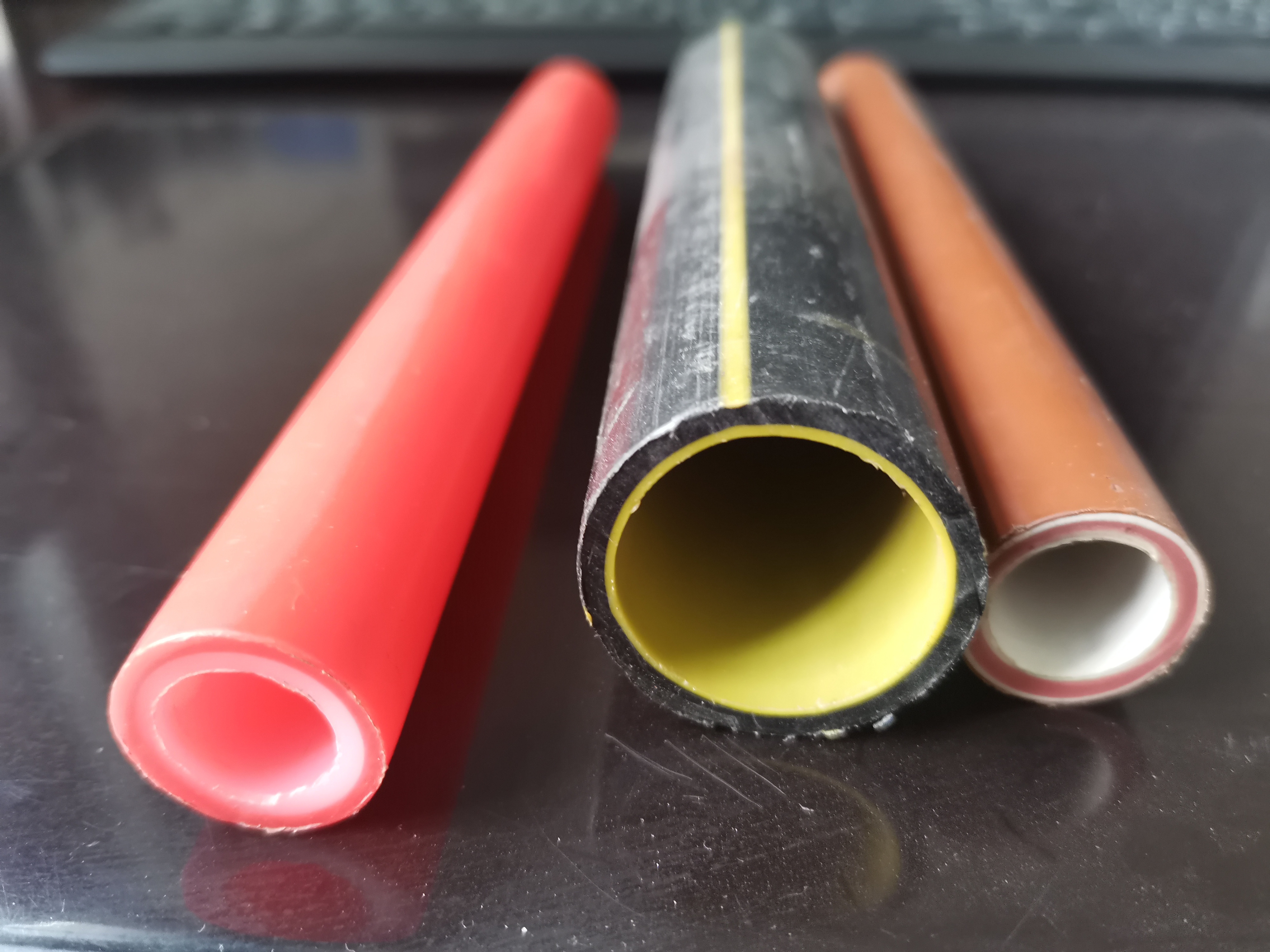

This production line can be used to produce a variety of pipes. The applicable raw materials are PP, HDPE, PPR, ABS, PERT and etc.

It produces single color pipe by monochrome extruder, while multilar pipe by multiple extruder and co-extrusion die head and mould. it also can be used to produce big diameter pipe, such as water supply pipe and gas pipe.

|

model

|

pipe diameter range(mm)

|

power(kw)

|

output(kg/h)

|

screw diameter(mm)

|

|

SJ-65/33

|

16-63

|

45

|

150

|

65

|

|

SJ-75/33

|

20-110

|

55

|

180

|

75

|

|

SJ-90/33

|

50-200

|

90

|

250

|

90

|

|

SJ-65/38

|

75-250

|

110

|

350

|

65

|

|

SJ-75/38

|

110-315

|

160

|

500

|

75

|

|

SJ-120×38

|

315-630

|

280

|

1200

|

120

|

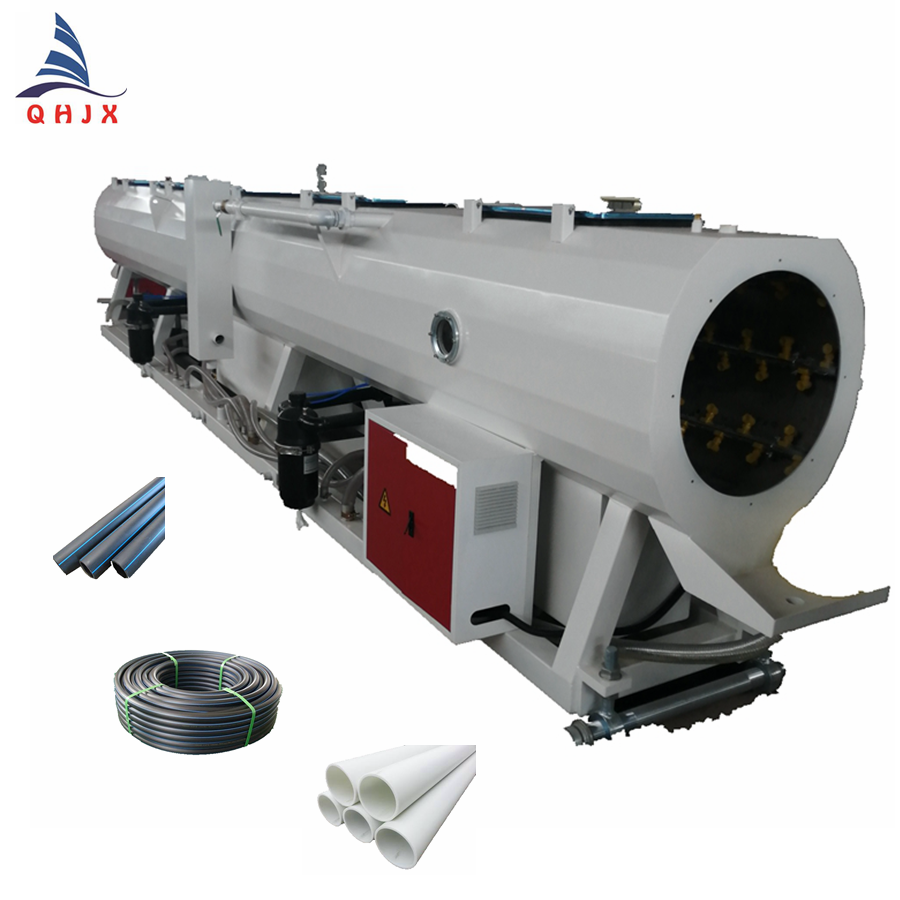

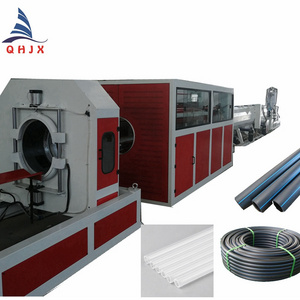

THE WHOLE PP PE PIPE PLASTIC EXTRUSION MACHINERY LINE

SINGLE-SCREW EXTRUDER

The high-efficiency single screw extruder adopts a two-stage overall design, strengthening the plasticizing function, ensuring high-speed, high-performance, and stable extrusion. The special barrier comprehensive mixing design ensures the mixing effect of the material, and the high shear and low melting plasticizing temperature ensures the high-performance, low-temperature, and low-pressure metering extrusion of the material.

The function of die head and mold is to further compact and plasticize the plasticized melt, which enters the annular

cross-section flow channel after diversion and is cooled and shaped into a tube blank.

We can customize mold and sizing sleeve size according to customer requirements.

cross-section flow channel after diversion and is cooled and shaped into a tube blank.

We can customize mold and sizing sleeve size according to customer requirements.

By using the same die head and model, different diameter pipes can be obtained by selecting different diameter sizing sleeves and

controlling the vacuum degree to expand and shrink the pipe blank.

controlling the vacuum degree to expand and shrink the pipe blank.

By using a spray cooling box equipped with an inlet pipe, a first connecting pipe, and a second connecting pipe, combined with a rotating cylinder, nozzle, gear, and tooth, the rotating cylinder can rotate and spray water evenly, improving the spraying efficiency of the device and making it convenient to use.

It can further cool the tube blank to shape it.

For different diameter pipes and extrusion speed requirements, we have developed various traction machines, including 2 tracks.

traction machines, 3 claw traction machines, 4 claw traction machines, 6 claw track traction machines, and etc.

The traction machine has a wide adjustable range, stable and reliable operation, and low noise.

traction machines, 3 claw traction machines, 4 claw traction machines, 6 claw track traction machines, and etc.

The traction machine has a wide adjustable range, stable and reliable operation, and low noise.

The characteristics of dust-free cutting machines include no chips, no noise, low power, and other advantages.

Energy saving, no waste of raw materials, and low cost. The end face of the pipe cutting is smooth and vertical.

AUTOMATIC UNLOADING RACK

The length of rack is 4m or 6m according to pipe size.

Table made of stainless steel.

Unloading method: pneumatic

Unloading method: pneumatic

It is used in conjunction with the pipe production line produced by our factory to achieve online automatic winding.

It can be rolled online and arranged neatly. It can be fully digitized by a computer, with a PLC integrated control system or a light rod cable arrangement mechanism. There are two types, single station and dual station.

Hot Searches