- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

200*100*100

-

Weight:

-

500 KG

-

Name:

-

Small Potato Chips Machine

-

Usage:

-

Food Industry Equipment

-

Function:

-

High Efficiency

-

Type:

-

Semi Auto

-

Application:

-

Snack Food Industry

-

Keywords:

-

Industrial Potato Chips Production Line

-

Feature:

-

High Efficiency Easy Operate

-

Final products:

-

Fired Potato Chips

-

Material:

-

304stainless Steel

-

Capacity:

-

30-40kg/ Hour

Quick Details

-

Marketing Type:

-

New Product 2021

-

Brand Name:

-

GTM

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220v

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

200*100*100

-

Weight:

-

500 KG

-

Name:

-

Small Potato Chips Machine

-

Usage:

-

Food Industry Equipment

-

Function:

-

High Efficiency

-

Type:

-

Semi Auto

-

Application:

-

Snack Food Industry

-

Keywords:

-

Industrial Potato Chips Production Line

-

Feature:

-

High Efficiency Easy Operate

-

Final products:

-

Fired Potato Chips

-

Material:

-

304stainless Steel

-

Capacity:

-

30-40kg/ Hour

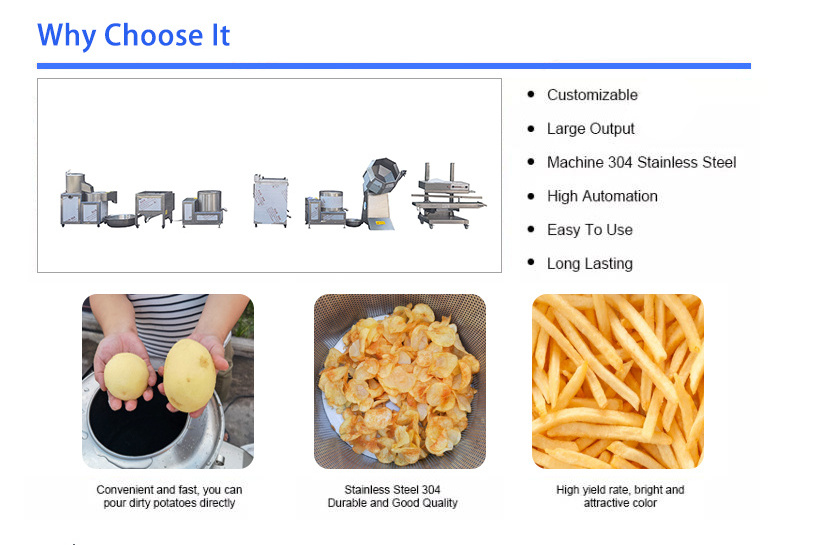

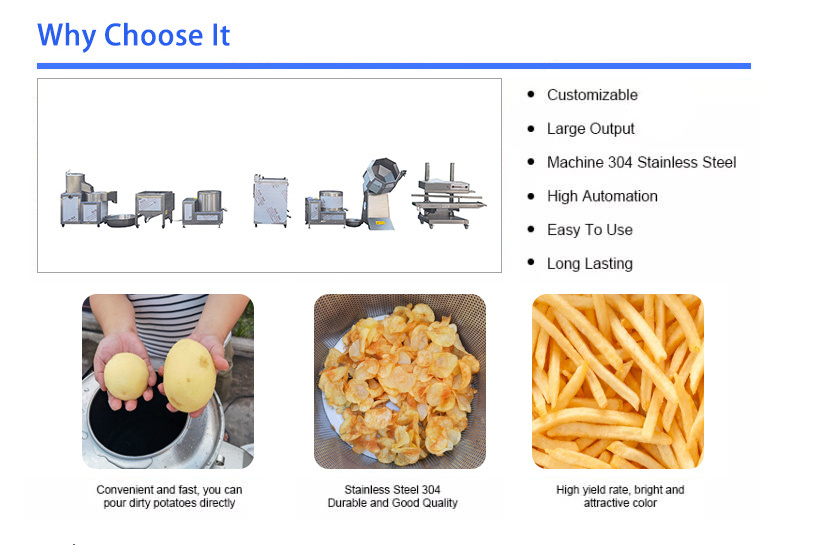

Final Prpduct Display

This production line can process and produce fried banana chips, potato chips, potato chips, taro chips, cassava chips, etc., and can also be customized for you according to your needs

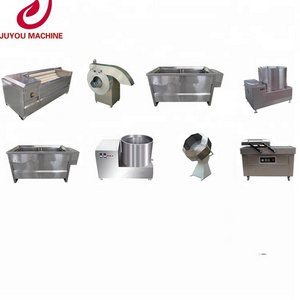

Product Description

|

Name

|

potato wash,peel,cut machine

|

Blanching machine

|

De-water machine

|

|

Capacity

|

200-300kg/hour

|

20-30kg every time

|

400kg/hour

|

|

Size

|

1000*550*1160mm

|

700*650*855mm

|

1000*600*870mm

|

|

Weight

|

93Kg

|

55Kg

|

130Kg

|

|

Power Supply

|

1.1Kw/220v/380v

|

12Kw/220v/380v

|

1.1Kw/220V/380V

|

|

Material

|

SS304

|

SS304

|

SS304

|

|

Name

|

Frying Machine

|

De-oil machine

|

Flavoring machine

|

|

Capacity

|

20-30Kg every time

|

400kg/hour

|

100-400Kg/hour

|

|

Size

|

775*700*1200mm

|

1000*600*870mm

|

1245*905*1400mm

|

|

Weight

|

70Kg

|

130Kg

|

129Kg

|

|

Power Supply

|

12Kw/220v/380v

|

1.1Kw/220V/380V

|

0.5Kw/220v/380v

|

|

Material

|

SS304

|

SS304

|

SS304

|

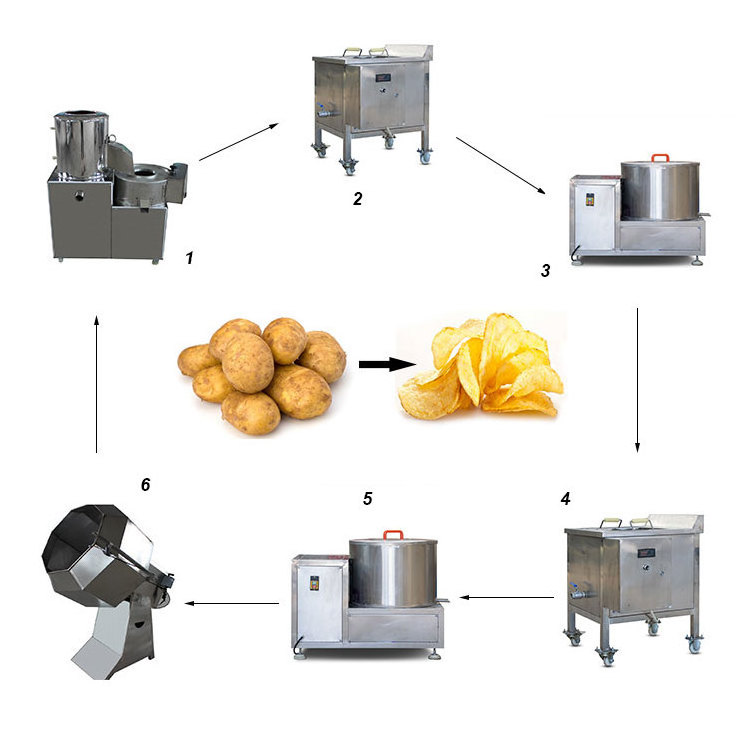

Working Process

|

No.

|

Machine Name

|

Function

|

|

Step 1

|

Potato wash,peel,cut machine

|

Wash ,peel and cut potato to chips or strips

|

|

Step 2

|

Blanching Machine

|

wash out the starch on the surface of the potato and protect the color

|

|

Step 3

|

De-water machine

|

remove the extra water on the surface of the chips .

|

|

Step 4

|

Frying machine

|

deep fry the potato chips

|

|

Step 5

|

De-oil machine

|

deep fry the potato chips

|

|

Step 6

|

Flavoring machine

|

seasoning the chips

|

|

Step 7

|

Heat sealing machine

|

packing potato chips

|

Our Advantages

1. We are a manufacturer. Compared with trading companies, the price and product quality are more competitive, and the after-sales service is more guaranteed

2. We use world-famous brand plc, servo motor, touch screen, etc., machines runs more smoothly, easier to operate, high accuracy, and long service life

3. We provide English manuals to let you understand and use the machines more quickly

4. One-year warranty and lifetime technical support

5. Free parts and wearing parts for some models

3. We provide English manuals to let you understand and use the machines more quickly

4. One-year warranty and lifetime technical support

5. Free parts and wearing parts for some models

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches