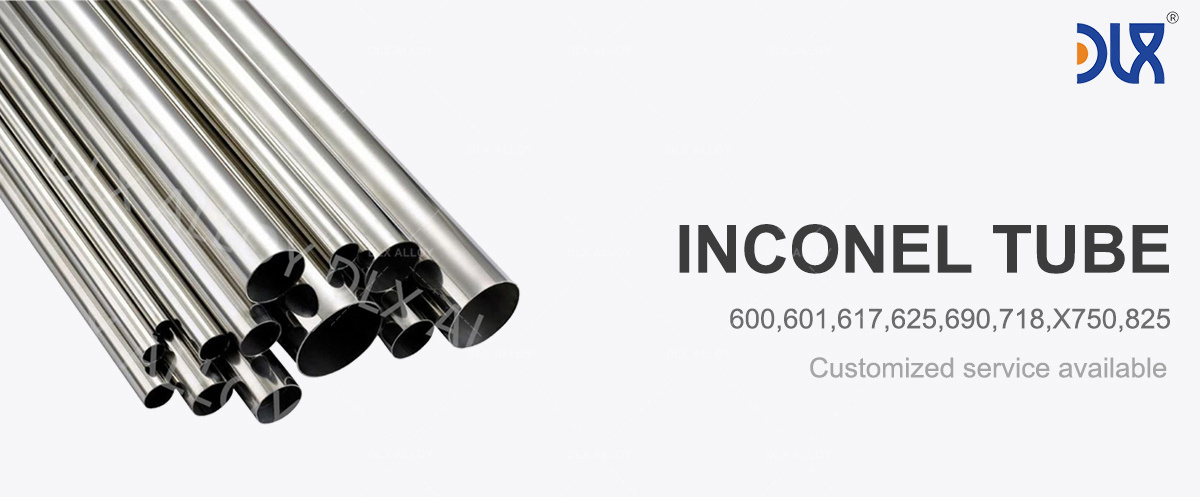

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

inconel 600

-

Shape:

-

wire, flat wire, strip, bar, plate, tube, wire, flat wire, strip, bar, plate, tube

-

Material:

-

inconel 600

-

Chemical Composition:

-

ni cr

-

Certificate:

-

ISO9001,ROHS, TUV

-

Use for:

-

Heating elements

-

Sample:

-

available

-

Size:

-

Customized Size

-

Feature:

-

High Corrosion Resistance

-

Advantage:

-

China Top Ranking

-

Style:

-

Austenitic nickel-chromium-based superalloys

-

OEM:

-

Accpet

-

Surface:

-

Bright Finished

Quick Details

-

Application:

-

food processing

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DLX

-

Model Number:

-

inconel 600

-

Shape:

-

wire, flat wire, strip, bar, plate, tube, wire, flat wire, strip, bar, plate, tube

-

Material:

-

inconel 600

-

Chemical Composition:

-

ni cr

-

Certificate:

-

ISO9001,ROHS, TUV

-

Use for:

-

Heating elements

-

Sample:

-

available

-

Size:

-

Customized Size

-

Feature:

-

High Corrosion Resistance

-

Advantage:

-

China Top Ranking

-

Style:

-

Austenitic nickel-chromium-based superalloys

-

OEM:

-

Accpet

-

Surface:

-

Bright Finished

Product Description

|

Steel grade

|

Inconel 600

|

Inconel 601

|

Inconel 625

|

Inconel 718

|

Inconel 725

|

Inconel X-750

|

||||||

|

Corresponding brand

|

N06600/2.4816/1Cr15Ni75Fe8/NS312/CY40

|

N06601/2.4851/1Cr23Ni60Fe13AI/NS313

|

N06625/2.4856/0Cr20Ni65Mo10bN4/NS336

|

N07718/2.4668/GH4169

|

N07725

|

N07750/2.4669/GH4145

|

||||||

|

Chemical composition%

|

|

|

|

|

|

|

||||||

|

C≤

|

0.150

|

0.100

|

0.100

|

0.080

|

0.030

|

0.080

|

||||||

|

Mn≤

|

1.00

|

1.00

|

0.50

|

0.35

|

0.35

|

1.00

|

||||||

|

P≤

|

/

|

/

|

0.015

|

0.015

|

0.015

|

/

|

||||||

|

S≤

|

0.015

|

0.015

|

0.015

|

0.015

|

0.010

|

0.010

|

||||||

|

Si≤

|

0.50

|

0.50

|

0.50

|

0.35

|

0.20

|

0.50

|

||||||

|

Cr≤

|

14.0-17.0

|

21.0-25.0

|

20.0-23.0

|

17.0-21.0

|

19.0-22.5

|

14.0-17.0

|

||||||

|

Ni≤

|

≥72.0

|

58.0-63.0

|

≥58.0

|

55.0-59.0

|

55.0-59.0

|

≥70

|

||||||

|

Mo

|

/

|

/

|

8.0-10.0

|

2.8-3.3

|

7.0-9.5

|

/

|

||||||

|

Cu

|

≤0.50

|

≤1.50

|

/

|

≤0.30

|

/

|

≤0.50

|

||||||

|

N

|

/

|

/

|

/

|

|

/

|

/

|

||||||

|

Nb

|

/

|

/

|

3.15-4.15

|

4.75-5.50

|

2.75-4.00

|

0.70-1.20

|

||||||

|

other

|

Fe:6.0-10.0

|

Al:1.0-1.7

|

Co:≤1.0Ai:≤0.40Tr:0.40Fe:≤5.0

|

AI:0.20-0.80Ti:0.65-1.15B≤0.006

|

Tr:1.0-1.7AI≤0.35

|

Co:≤1.0 AI:0.4-1.0Tr:0.25-2.75Fe:5.0-9.0

|

||||||

Specifications

• We can supply all kinds of bar, forging, ring, hot rolled plate, cold rolled plate, strip, pipe and wire.

Plate and strip are generally supplied after hot or cold rolling, annealing or solid solution, pickling and polishing.

• Rods, forgings and rings may be supplied in the form of forging or hot rolling;It can also be supplied with solid solution after forging.The bar can be polished or polished after solid solution.When the order is required, it can be placed in the cold drawing state.

• Silk can be supplied in solid solution state.For silk materials with nominal diameter or thickness less than 6.35mm, it can be provided with 50% ~ 65% cold drawing deformation after solid dissolution.Silk material with nominal diameter or side length greater than 6.35mm shall be supplied with no less than 30% cold drawing deformation after solid solution treatment.For silk materials with nominal diameter or side length not exceeding 0.65mm, according to the requirements of solid solution treatment, no less than 15% cold drawing deformation is provided.

Plate and strip are generally supplied after hot or cold rolling, annealing or solid solution, pickling and polishing.

• Rods, forgings and rings may be supplied in the form of forging or hot rolling;It can also be supplied with solid solution after forging.The bar can be polished or polished after solid solution.When the order is required, it can be placed in the cold drawing state.

• Silk can be supplied in solid solution state.For silk materials with nominal diameter or thickness less than 6.35mm, it can be provided with 50% ~ 65% cold drawing deformation after solid dissolution.Silk material with nominal diameter or side length greater than 6.35mm shall be supplied with no less than 30% cold drawing deformation after solid solution treatment.For silk materials with nominal diameter or side length not exceeding 0.65mm, according to the requirements of solid solution treatment, no less than 15% cold drawing deformation is provided.

Produce Details

Manufacturing Technique

Application

Alloy 625

own a very good corrosion resistance in many media, especially with excellent resistance to pitting, crevice corrosion,intercrystalline corrosion, and erode in oxide, also good resistance to inorganic acid corrosion, such as nitric acid, phosphoric acid, sulfuric acid and hydrochloric acid.

Alloy 625 can resist the alkali and organic acid corrosion in the oxidation and reduction environment. Effect resists the chloride reduction stress corrosion cracking. Normally no corrosion in the sea-water and industry environments since high corrosion resistance to the sea-water and salting liquid,as well as in high temperature, without sensitivity during welding.

Alloy 625 have the resistance to oxidation and carbonizing in the static and cycle environments, also hacve the resistance the chlorine corrosion.

Alloy 625 can resist the alkali and organic acid corrosion in the oxidation and reduction environment. Effect resists the chloride reduction stress corrosion cracking. Normally no corrosion in the sea-water and industry environments since high corrosion resistance to the sea-water and salting liquid,as well as in high temperature, without sensitivity during welding.

Alloy 625 have the resistance to oxidation and carbonizing in the static and cycle environments, also hacve the resistance the chlorine corrosion.

Hot Searches