- Product Details

- {{item.text}}

Quick Details

-

Power:

-

120KW

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

35*5*4m

-

Product name:

-

uht milk production line

-

Production capacity:

-

100kg-2T/H

-

Material:

-

SUS304

-

Function:

-

uht milk sterilizer machine package

-

Usage:

-

small scale uht milk processing plant

-

After-sales Service:

-

overseas engineer service available

-

Capacity:

-

200L-5000l/h

-

Final product:

-

uht milk

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Jumpfruits

-

Voltage:

-

380v

-

Power:

-

120KW

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

35*5*4m

-

Product name:

-

uht milk production line

-

Production capacity:

-

100kg-2T/H

-

Material:

-

SUS304

-

Function:

-

uht milk sterilizer machine package

-

Usage:

-

small scale uht milk processing plant

-

After-sales Service:

-

overseas engineer service available

-

Capacity:

-

200L-5000l/h

-

Final product:

-

uht milk

-

Certification:

-

ISO

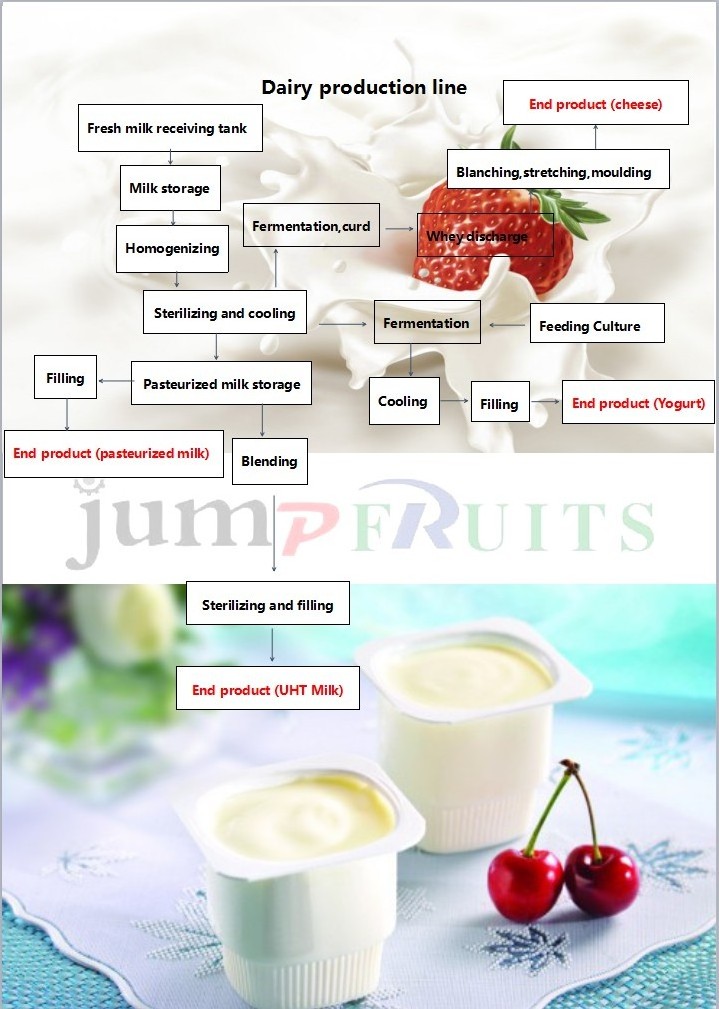

Milk production line mainly produces a variety of flavors of sterilized milk, uht milk pasteurized milk and reconstituted milk, peanut milk, milk and so on, a full set of fresh milk production line mainly include: breast milk collection system, mixing system, net and standardization system, homogeneous degassing system and sterilization system, filling system, etc.

Milk a full set of equipment:

Storage tanks - - - the milk tank - hot and cold beverage pump cylinder cream separator - to take off the angry machine - mixing cylinder - homogenizer - ultra high temperature sterilization machine - plate heat exchanger - seed tank fermentation tank - sterilization machine, automatic filling machine.

Advantages:

1. Users can design special requirements

2. In the same production line can produce different end products

3. A short incubation time

4. Can be accurately added and mixed aromatic substances

5. high Yield, low loss

6. Application of high technology to save energy 20%

7. The entire production process monitoring systems

8. Image, intuitive display, print all process parameters

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc .

Our company adheres to the purpose of "Quality and Service Branding", after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

UHT milk sterilizer machine

2 Products type: 1 or 2 or more kinds.

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

Pre-sales service

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer's technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.