- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

hwasen

-

Voltage:

-

380v or change as request

-

Dimension(L*W*H):

-

5x3.5x5.8m

-

Power (kW):

-

10

-

Weight:

-

2200kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Online support

-

machine color:

-

as like

-

machine:

-

Extruder/film blowing machine

-

Product:

-

mono layer PE bag film

-

blown machine:

-

Biodegradable plastic bag production line

-

Color:

-

as like

-

Name:

-

Extruder/film blowing machine

-

Automatic Grade:

-

automatic

-

Power:

-

18.5kw

-

Certification:

-

ce

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

hwasen

-

Voltage:

-

380v or change as request

-

Dimension(L*W*H):

-

5x3.5x5.8m

-

Power (kW):

-

10

-

Weight:

-

2200kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Online support

-

machine color:

-

as like

-

machine:

-

Extruder/film blowing machine

-

Product:

-

mono layer PE bag film

-

blown machine:

-

Biodegradable plastic bag production line

-

Color:

-

as like

-

Name:

-

Extruder/film blowing machine

-

Automatic Grade:

-

automatic

-

Power:

-

18.5kw

-

Certification:

-

ce

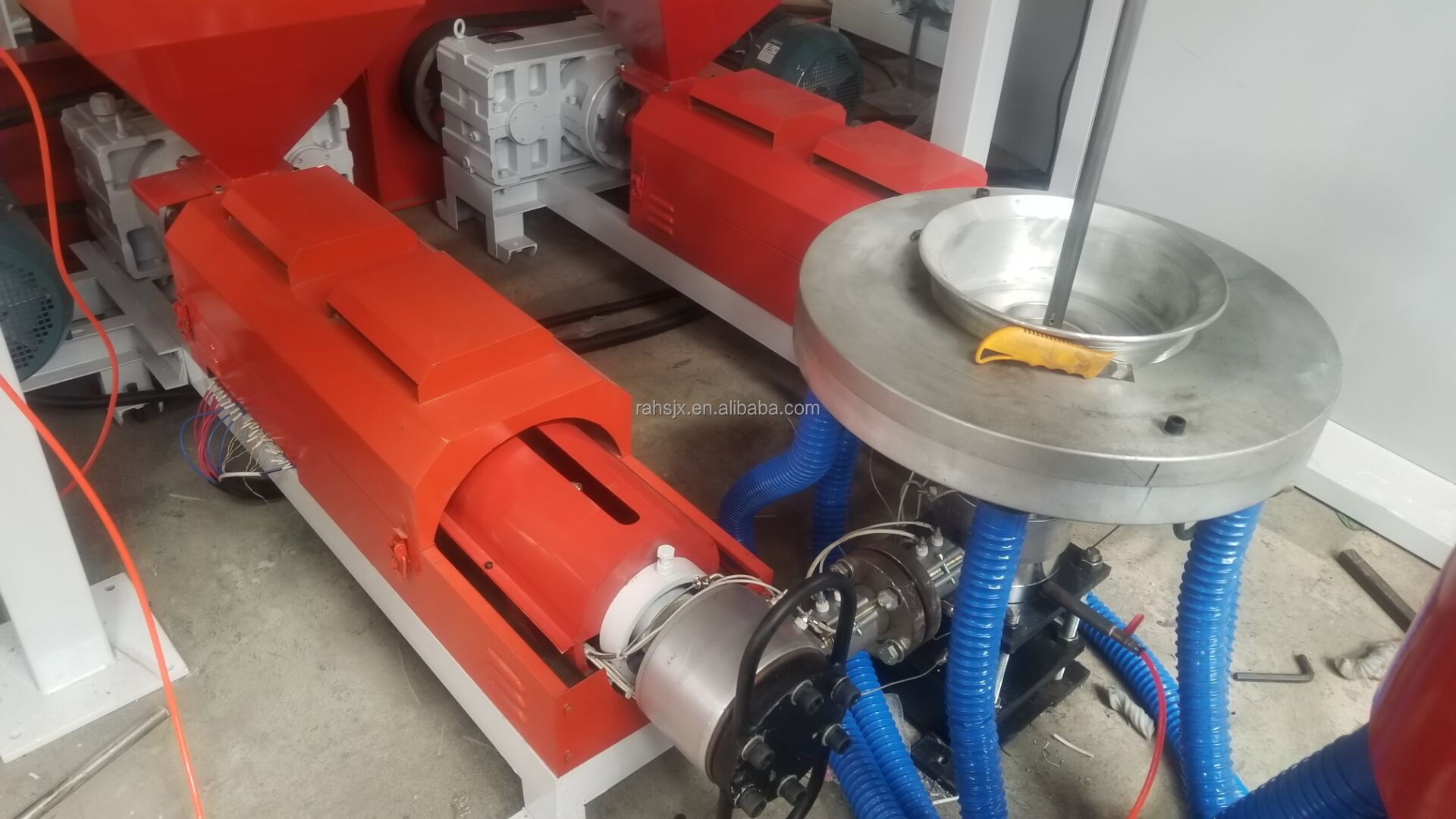

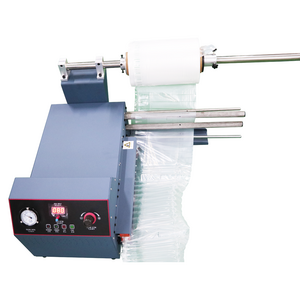

SJ50-600 multi-function air bubble wrap pillow filling packing film blowing machine with CE

1.Feature:

1.1 The machine take the HDPE or LDPE as raw material, through heating, extrusion, blowing, stretct, winder and final be roll in film.

1.2 The finished plastic thin film is widely used for supermarket bag, garbage bag, various plastic package bag, farmland film. cote film and compound thin film.

2.Main Technical Specification

|

MODEL |

SJ50-600 |

SJ55-800 |

|

Suitable raw material HDPE LDPE LLDPE |

||

|

Width of single film |

600mm |

800mm |

|

Film thickness (HD) |

0.009-0.05mm |

0.009-0.05mm |

|

Film thickness (LD) |

0.025-0.1mm |

0.025-0.1mm |

|

Max output(HD) |

30kg/hr |

50kg/h |

|

Max. output (LD)) |

35 kg/hr |

55kg/h |

|

power-consume |

18kw |

26kw |

|

Cover dimension |

5.0×2.0×4.0m |

5.0×2.2×4.2m |

|

EXTRUDER |

||

|

Screw diameter |

Φ50mm |

Φ55mm |

|

Screw L/D |

28:1 |

28:1 |

|

Screw material |

SACM-645/38CRMOLA |

SACM-645/38CRMOLA |

|

Cylinder material |

SACM-645/38CRMOLA |

SACM-645/38CRMOLA |

|

Cylinder cooling |

370w×3 |

370w×3 |

|

Driving motor |

11kw |

15kw |

|

Temperature control |

3unit |

3unit |

|

TYPE OF DIE |

||

|

Die size |

60/80mm |

80/100mm |

|

Temperature control |

3 unit |

3unit |

|

Air ring |

1pcs |

1pcs |

|

Air blower |

1.5kw |

2.2kw |

|

Center steady stick |

1pcs |

1pcs |

|

TAKE-UPUNIT |

||

|

ROLLER WIDTH |

165×650mm |

165×850mm |

|

Height adjust |

600mm |

800mm |

|

Take up speed |

10-80m/min |

10-80m/min |

|

TAKE-UP MOTOR |

0.75kw |

0.75kw |

3.Picture showroom:

1) rotary die head extrusion

2) bubble

3) traction part

4) controller box panel

5) film blowing machine factory show

6) rewind film quality show

If you are looking for a reliable supplier and a long term relationship partner in China , Please contact us

Ellen qiu:

whatsapp:+86-15057324868 skype:inthesky1241

wechat:ellenqiu1 email:cnhsjx rahsjx.com