- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DLSTECH

-

Product name:

-

Reciprocating Chain Grate

-

Keywords:

-

Industrial incinerator

-

Fuels:

-

Coal, biomass, plam

-

Material:

-

Cast Iron

-

Usage:

-

Heating, Oxidation, Corrosion, Resistar

-

Port:

-

Dalian

-

Function:

-

Heating,Burning, Drying

-

Size:

-

Customised Sizes

-

Packing:

-

Iron Box

-

color:

-

OEM

Quick Details

-

Type:

-

GRATE STOKER

-

Weight (KG):

-

20000

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

DLSTECH

-

Product name:

-

Reciprocating Chain Grate

-

Keywords:

-

Industrial incinerator

-

Fuels:

-

Coal, biomass, plam

-

Material:

-

Cast Iron

-

Usage:

-

Heating, Oxidation, Corrosion, Resistar

-

Port:

-

Dalian

-

Function:

-

Heating,Burning, Drying

-

Size:

-

Customised Sizes

-

Packing:

-

Iron Box

-

color:

-

OEM

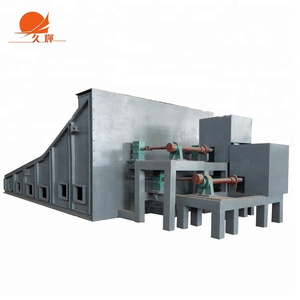

Reciprocating Type Grate Stoker

The grate is stepped and is formed by stacking the same arrangement of fixed grate pieces and movable grate pieces. The movable grate is reciprocated to make the coal move evenly downwards, and the stroke is generally 70-110 mm. When the coal quality is poor, the large stroke is selected.

The coal seam is squeezed, tumbling, agitated as the moving grate moves, and some of the new coal is pushed onto the hot coal seam that has been ignited underneath, while the moving grate sheet returns some of the hot coal particles that have been ignited back to the unburned Underneath the new coal seam, the fuel layer has the characteristics of double-sided ignition. Unlike the chain grate, there is relative movement between the coal seam and the grate. The loose coal seam can increase its gas permeability, and the coal particles squeeze and rub each other. A layer of ash shells wrapped around the hot coal particles is used to help burn off the coke. The reciprocating motion of the grate can break the coke block with weak cohesiveness and has a certain ignition effect.

In short, the inclined reciprocating grate has a simple structure, is easy to process and manufacture, is easy to use and maintain, and has low metal consumption. Compared with the chain grate, it can be adapted to burn inferior fuel, such as type II bituminous coal, class I bituminous coal, lignite, and lean coal.

Advantages And Features:

1.Apply to produce high pressure steam or hot water in range from 3,450-60,000 lbs/h.

2.The structure of fixed and removable grates can greatly increase the combustion efficient of incombustibles material.

3.The humidity of material range is from 30%-50%.

4.The temperature range is from 550ºC-1200ºC.