- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HAIQI

-

Model Number:

-

HQ-SRF2MW

-

Output Voltage (V):

-

380

-

Application:

-

Making Electricity

-

Color:

-

Customers' Requirement

-

Raw material:

-

Biomass Straw Sawdust Woodchips

-

Efficiency:

-

High Effiency

-

Operation:

-

Automatic Control

-

Usage:

-

Power Application

Quick Details

-

Warranty:

-

1 Year

-

Marketing Type:

-

Gasification Electricity Product

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

HAIQI

-

Model Number:

-

HQ-SRF2MW

-

Output Voltage (V):

-

380

-

Application:

-

Making Electricity

-

Color:

-

Customers' Requirement

-

Raw material:

-

Biomass Straw Sawdust Woodchips

-

Efficiency:

-

High Effiency

-

Operation:

-

Automatic Control

-

Usage:

-

Power Application

Biomass Wood Chips Burner

Biomass Wood Powder Burner

Biomass Wood Pellet Burner

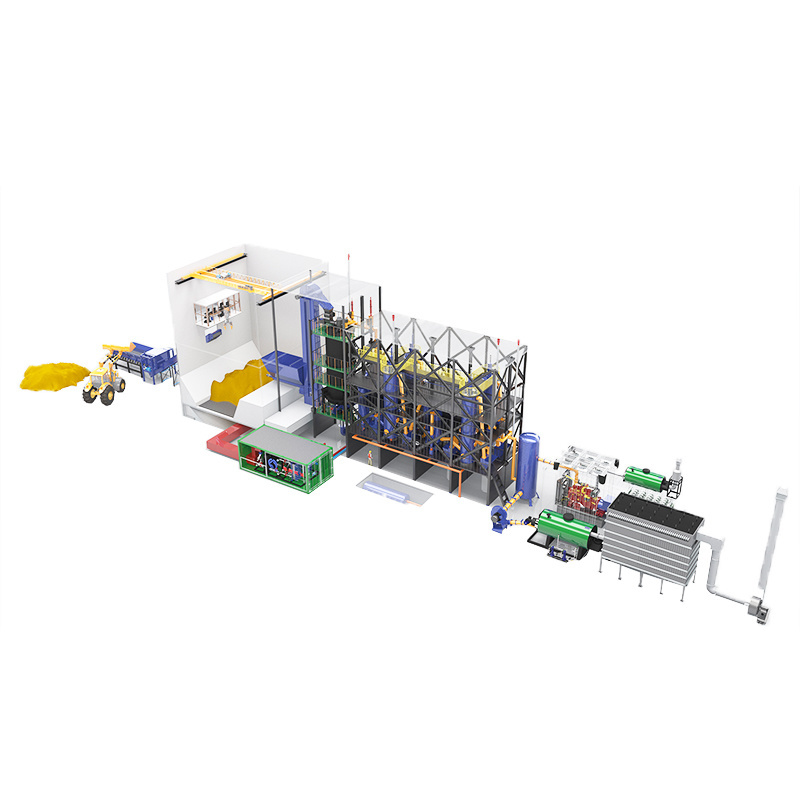

Biomass Gasification Power Plant

Automatic Slag Removal Burner

Waste Gasification Power Plant

Features of Haiqi Biomass Gasifier:

reasonable structure, high degree of automation, good furnace body protection, obvious environmental protection advantages, wide range of raw materials, low operating cost. 1kw woody biomass produce 2-3m3/h syngas, syngas heat value 1100-1500kcal/m3.

Biomass gasification is the use of heat to transform solid biomass or other carbonaceous solids into a synthetic

“natural-gas-like” flammable fuel. Through biomass gasifier, we can convert nearly any dry organic matter into a clean burning fuel that can replace fossil fuel in most use situations. Whether starting with wood chips or walnut shells, construction debris or agricultural waste, biomass gasifier power will transform common “waste” into a flexible gaseous fuel you can use biomass gasifier to run your internal combustion engine, cooking stove, furnace or flamethrower.

“natural-gas-like” flammable fuel. Through biomass gasifier, we can convert nearly any dry organic matter into a clean burning fuel that can replace fossil fuel in most use situations. Whether starting with wood chips or walnut shells, construction debris or agricultural waste, biomass gasifier power will transform common “waste” into a flexible gaseous fuel you can use biomass gasifier to run your internal combustion engine, cooking stove, furnace or flamethrower.

|

ITEM

|

HQ-SR1400

|

HQ-SR1800

|

HQ-SR2200

|

HQ-SR2400

|

|

Heat supply capacity

|

300,000kcal/h

|

600,000kcal/h

|

900,000kcal/h

|

1,200,000kcal/h

|

|

Fuel

|

100-150kg

|

200-300kg

|

350-450kg

|

500-600kg

|

|

Gas produce

|

200-300m3

|

400-600m3

|

700-900m3

|

1000-1200m3

|

|

Power

|

9.2kw

|

10.7kw

|

11.5kw

|

13.5kw

|

|

pressure Kpa

|

-15*10 -30*10

|

-15*10 -30*10

|

-15*10 -30*10

|

-15*10 -30*10

|

|

gas value

|

1200-1500kcal/m3

|

1200-1500kcal/m3

|

1200-1500kcal/m31000-1200m3

|

1200-1500kcal/m31600-1800m3

|

|

Moisture

|

15%-20%

|

15%-20%

|

15%-20%

|

15%-20%

|

Application Of Biomass Gasifier :

Widely used in power generation gas, domestic gas, steam boilers, hot water boilers, industrial furnaces, incinerators, melting furnaces, kitchen equipment, drying equipment, food drying equipment, ironing equipment, paint baking equipment, industrial annealing furnaces , Asphalt heating equipment, die-casting machine, printing and dyeing industry, etc…

Biomass Pyrolysis Gasification Application

Utilization and Value of Biomass Gas:

Biomass pyrolysis gasification technology produces fuel gas as a mixed gas, in which the combustible components are mainly CO, H2,CH4, CmHn, etc., and the heating value is 1100~1500kcal/m³. One kilogram of straw can produce 1-1.5m³ biomass combustible gas.

After purification, this gas can be used to replace natural gas, coal gas, etc. for power generation, fire cooking, heating, etc.

After purification, this gas can be used to replace natural gas, coal gas, etc. for power generation, fire cooking, heating, etc.

Application Scenarios of Cogeneration of Biomass Gasification System

By Product Of Biochar :

The biochar is a by-product from biomass pyrolysis gasification, it can be used as activated carbon, barbecue carbon, carbon-based fertilizer to soil, animal feed additives,etc.

Economic Industrial Chain Driven By Biomass Gasification Polygeneration Technology

The Advantages Of Biochar To Soil:

●Water absorption and moisture retention, one ton of carbon absorbs 3 tons of water

●Adsorption and solidification of heavy metals

●Biochar can increase the low temperature by 1-3 degrees

●Biochar can loosen the soil and increase the air permeability of the soil

●Nitrogen fixation and fertilizer preservation, extend and increase the fertility of carbon-based carrier fertilizer

●Biochar can Inhibiting pests, preventing diseases and disasters

●Each ton of straw can produce 300-350kg black carbon

●Carbonaceous solids are called biological black carbon, which is a general term for mixtures under organic carbon, mainly cellulose, hydroxyl, acid organic acid derivatives, furans, pyrans, anhydrosugars, phenols, paraffins and olefinic hydrocarbons Complex organic carbon mixtures such as derivatives.

●Adsorption and solidification of heavy metals

●Biochar can increase the low temperature by 1-3 degrees

●Biochar can loosen the soil and increase the air permeability of the soil

●Nitrogen fixation and fertilizer preservation, extend and increase the fertility of carbon-based carrier fertilizer

●Biochar can Inhibiting pests, preventing diseases and disasters

●Each ton of straw can produce 300-350kg black carbon

●Carbonaceous solids are called biological black carbon, which is a general term for mixtures under organic carbon, mainly cellulose, hydroxyl, acid organic acid derivatives, furans, pyrans, anhydrosugars, phenols, paraffins and olefinic hydrocarbons Complex organic carbon mixtures such as derivatives.

Biomass gasification power generation in Russia

Hot Searches