- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

PERFECT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

Mining Rail Flat Car

-

Color:

-

Customized

-

Application:

-

Industrial Filed

-

Material:

-

Q235

-

Capacity:

-

1-300ton

-

Certificates:

-

CE ISO SGS

-

Warranted:

-

12 months

-

Usage:

-

Heavy duty

-

Table size:

-

Customized

Quick Details

-

Warranty:

-

2 years

-

Weight (KG):

-

300

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

PERFECT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

Mining Rail Flat Car

-

Color:

-

Customized

-

Application:

-

Industrial Filed

-

Material:

-

Q235

-

Capacity:

-

1-300ton

-

Certificates:

-

CE ISO SGS

-

Warranted:

-

12 months

-

Usage:

-

Heavy duty

-

Table size:

-

Customized

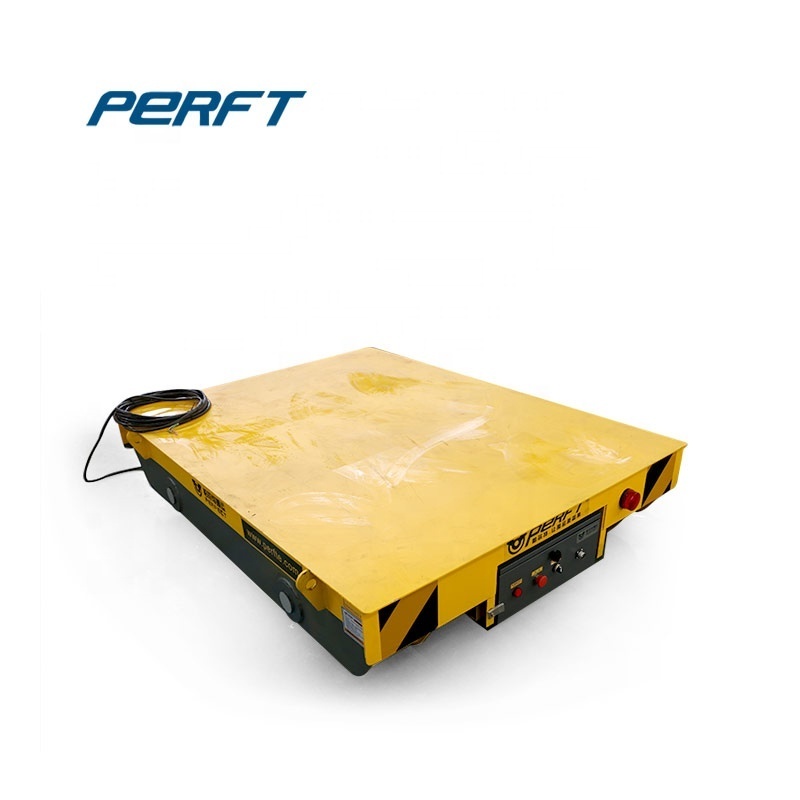

Motorised Steel Transfer Cart On Rail For Outdoor Shipyard Material Handling

| Model | BTL-2t | BTL-20t | BTL-50t | BTL-100t | BDGS-150t | |

| Rated Load(t) | 2 | 20 | 50 | 100 | 150 | |

| Table Size(mm) | Length(L) | 2000 | 4000 | 5500 | 6500 | 10000 |

| Width(W) | 1500 | 2200 | 2500 | 2800 | 3000 | |

| Heigth(H) | 450 | 550 | 650 | 850 | 1200 | |

| Wheel Base(mm) | 1200 | 2800 | 4200 | 4900 | 7000 | |

| Rail Inner Gauge(mm) | 1200 | 1435 | 1435 | 2000 | 2000 | |

| Wheel Diameter(mm) | 270 | 350 | 500 | 600 | 600 | |

| Wheel Quantity | 4 | 4 | 4 | 4 | 8 | |

| Ground Clearance(mm) | 50 | 50 | 50 | 75 | 75 | |

| Running Speed(min) | 0-25 | 0-20 | 0-20 | 0-20 | 0-18 | |

| Motor Power(kw) | 0.8 | 2.5 | 5.5 | 11 | 15 | |

| Running Distance(m) |

0-20

|

|||||

| Max Wheel Load(KN) | 14.4 | 77.7 | 174 | 343.8 | 265.2 | |

| Reference Weight(t) | 2.3 | 5.5 | 7.6 | 13.9 | 26 | |

| Recommended Rail Model | P15 | P24 | P43 | QU100 | QU100 | |

NOTES:

- Flat deck or fixtures for transporting special payload;

- Custom deck configurations may include lift, tilt, or rotate function;

- Payload from 1 ton to 300 tons;

- Fixed speed or variable speed capabilities;

- With forward or backing driving;

- Options for automatic control;

- Available safety equipment includes horn, lights, emergency stop, bumpers and detector.

- 1. Moving the steel plate from storage area to cutting process area by crane;

- 2. According to the cutting drawing cutiting steel plate by the numercial control cutting machine;

- 3. The mobile welding machine is used for precise welding of diferent parts of the frame;

- 4. Fine grinding and weld inspection of the weld joint;

- 5. For every car primer spray, toccat, perfect antirust, ensure th ebeauftiful appearance;

- 6. Installation of the whole internal parts of the wheel and the car body;

- 7. Commissioning the vehicle operation and electrical parts, then test after completion of commissoning:

- 8. Zero load test and load test before shipping.

1. Q: What is the size and load of this Mining Rail Flat Car ?

A:The size and load of our this Mining Rail Flat Car is customized design according to your requirement.

2. Q: How should I operate this Mining Rail Flat Car ?

A: The Mining Rail Flat Car is controlled by pendant & remote radio control. The controller could be push button or joy-sticker.

3. Q: Is there any braking system on this Mining Rail Flat Car ?

A: Yes, there are electromagnetic brakes on the Mining Rail Flat Car. When the Mining Rail Flat Car is power off, the brake will work automatically. And there are emergency stop buttons on the remoter and the Mining Rail Flat Car, you can push it for emergency stop.

4. Q:What is the warranty period? What kind of service do you offer in the warranty period?

A: The warranty period for our product is 12 months from the time we delivery, during the warranty period, we will send spare parts to you on our own cost if damaged because of bad quality, and we will guide you how to replace it. If necessary, our engineer is available to your factory for maintenance.

5. Q: How do you transport the Mining Rail Flat Car and what is the package ?

A: For the big part, we will pack it with tarpaulin and wood pallet on the bottom of the Mining Rail Flat Car to prevent it from moving. For the small part, we will pack it in wood case.

6. Q: What is the leading time, delivery term, and payment term ?

A: Usually our leading time is 45 days, for some special Mining Rail Flat Car, such as hydraulic lifting Mining Rail Flat Car, it maybe longer to 60 days. About the delivery term, we accept EXW, FOB, CIF, DDU. About the payment, we accept T/T or L/C.