Slitting jumbo roll material into small tapes.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1500 KG

-

Product name:

-

Automatic bopp self adhesive tape making machine

-

Slitting Accurancy:

-

±0.1mm

-

Min-Sliting width:

-

12mm

-

Max-unwinding Diameter:

-

800mm

-

Max-slitting Speed:

-

200M/mm

-

Constant Tension:

-

Yes

-

Usage:

-

Bopp Packing Adhesive Tape

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Voltage:

-

380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LUNYOU MACHINERY

-

Weight:

-

1500 KG

-

Product name:

-

Automatic bopp self adhesive tape making machine

-

Slitting Accurancy:

-

±0.1mm

-

Min-Sliting width:

-

12mm

-

Max-unwinding Diameter:

-

800mm

-

Max-slitting Speed:

-

200M/mm

-

Constant Tension:

-

Yes

-

Usage:

-

Bopp Packing Adhesive Tape

-

Marketing Type:

-

Hot Product 2022

|

SPECIFICATIONS OF MODEL LY-211 SLITTING MACHINE

|

|

|

|

|||

|

Vaild width

|

|

1300mm/1600mm/customized

|

mm

|

|||

|

Diameter of paper core

|

|

76.2mm/customized

|

mm

|

|||

|

Min slitting width

|

|

12mm

|

|

|||

|

Max unwinding diameter

|

|

800mm

|

mm

|

|||

|

Max rewinding diameter

|

|

200mm(4 shafts exchange)

320mm(2 shafts exchange)

|

mm

|

|||

|

Rewinding speed

|

|

0-200m/min

|

|

|||

|

Voltage

|

|

380V, 50HZ, 3-Phase(changeable according to different countries)

|

|

|||

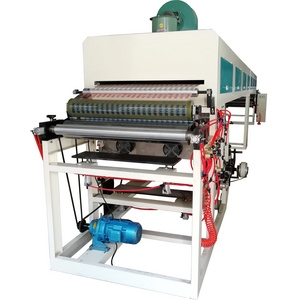

LY-211 Automatic Adhesive Tape Slitting Machine

Hot selling model

• Machine speed: 0-200m/min

• Suitable for the slitting and rewinding of super clear, transparent, common bopp adhesive tape

Features

1) Easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) Running in a high automatization and intellectualization, no pollution.

Slitting machine

Core wearing machine

Loading the prepared paper core.

Core cutting machine

Cutting the paper core.

Mini rewinding machine

Winding defective tapes.

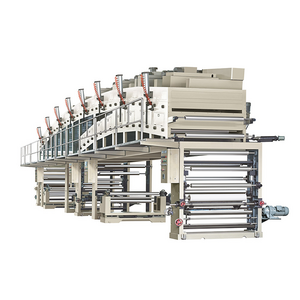

LY-600L Full Automatic Slitting Machine

Cutting and smoothing automaticlly

LY-211C Semi Automatic Slitting Machine

Cutting and smoothing manually

LY-211 Semi Automatic Slitting Machine

this model

WHY CHOOSE LUNYOU?

We have nearly 20 years of experience in manufacture of tape slitting, cutting and rewinding machine. Our machines are aimed at medium and high-end markets. It's based on our experienced design team and high quality imports parts. We also can make the machines for special popurse according to customer's request. High quality and reasonable price is our way to enjoy the popularity in the worldwide markets.

CUSTOMERS & EXHIBITIONS

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1

. Q: Are you a factory or trading company?

A: We are a factory and we have years of experience of

manufacturing slitting, rewinding and cutting machines.

2. Q: Does the machine be able to cut different size of tapes?

A: Yes absolutely, you can set any length by the PLC controler. O

ne width, one mold, our machine is easy to change the mold.

3. Q: Do you make machines according to specifications?

A: Yes, we do design different machines for special purpose.

4. Q: Do you have the manual book?

A: Yes, and if necessary, our engineers are available to service overseas. And our machines are highly automatic and easy to operate.

5. Q: How long does it usually take you to make the delivery?

A:As a rule, we deliver our machine within 1 month , and of cause it will take longer for special orders, but in no case would it take longer than 3 months.

6. Q: The voltage in our country is different from yours,does the machine can be changed?

A:Yes, we can make the change for customers.

7. Q: Where is your factory locatesd in , and how can I get there ?

A: Our address is No. 228 Fenglin Road, Shuangfeng Town, Taicang City, Jiangsu Province, China. And we are near by Shanghai, you can contact us when you arrive in Shanghai, we will pick you up.

8. Q: How about your warranty?

A: One year, wearing parts not included.

![[JT-GW500-A6]Rewinding Bopp Adhesive Tape Making Machine Automatic Coating Plastic Film Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/cb9133af055b3ad7b962b5e60352dadb.jpg!/rotate/180/sq/300)