- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2023

-

Power (kW):

-

35 kW

-

Weight (KG):

-

3000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage:

-

tyre retreading, rubbr vulcanization

-

advantage:

-

high efficiency

-

heating method:

-

electricity heating or steam heating

-

Raw material:

-

Used tire

-

Price:

-

Competitive

-

Working condition:

-

Stable and safe

-

Weight:

-

5-15 tons

-

Power(W):

-

1.5KW - 75 KW

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dafu

-

Voltage:

-

380v,50HZ

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2023

-

Power (kW):

-

35 kW

-

Weight (KG):

-

3000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage:

-

tyre retreading, rubbr vulcanization

-

advantage:

-

high efficiency

-

heating method:

-

electricity heating or steam heating

-

Raw material:

-

Used tire

-

Price:

-

Competitive

-

Working condition:

-

Stable and safe

-

Weight:

-

5-15 tons

-

Power(W):

-

1.5KW - 75 KW

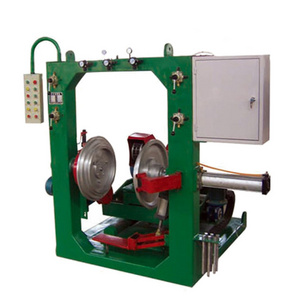

2023 Tire Vulcanizing Pot, Tyre Retreading Machine

horizontal vulcanizing pot, mainly used for vulcanized fly model rubber products, such as rubber shoes, hoses, cables, rubber roller boxes, adhesive tape, etc., and sometimes used for vulcanized model rubber products.

classification:

according to the vulcanized rubber products

Vulcanizing tank for rubber shoes

Vulcanizing pot

Adhesive tape and rubber roller vulcanizing pot

The structure is basically similar, but the vulcanizing pot used for vulcanized rubber and rubber roller prevents the rubber from heating and softening in the process of vulcanization, and is provided with an adhesive tape roll or a rubber roller rotating transmission device. Another, such as vulcanized rubber tube vulcanizing pot, generally use direct steam heating vulcanization, no hot air circulation device in the tank

according to the structure of the tank:

Direct heating vulcanizing pot

Indirectly heated vulcanizing pot

The tank is heated directly by steam heating and vulcanizing, and the indirect heating pot is mostly steam insulated and lined with steam. In the past, the indirect heating vulcanizing pot adopted a jacket structure, and the steam was heated and vulcanized in the jacket. But this kind of construction is troublesome and is no longer necessary. In addition, in order to obtain higher sulfidation temperature, a vulcanizing autoclave with electric heating has been developed in recent years

The main photos of the tyre autoclave

After service

1. Our company has professional installation team. We will install and test the production line at the customers’ place until the equipment produces the qualified products.

2. We supply the accessories all the year round. The warranty of the equipment is one year.

3. We are responsible for the technical consultation and service all the year round and solve all kinds of technical problems at any time.

4. We can help the customer to do the consignment and the relevant procedure for import and export.

5. Our company will supply the information of the seller for all kinds if raw materials and relevant information.

6. The Operating Instruction will go to the customers with the equipment