- Product Details

- {{item.text}}

Quick Details

-

Material:

-

PE/PP/PVC,wood/rice husk/straw

-

sanding:

-

wpc sanding machine

-

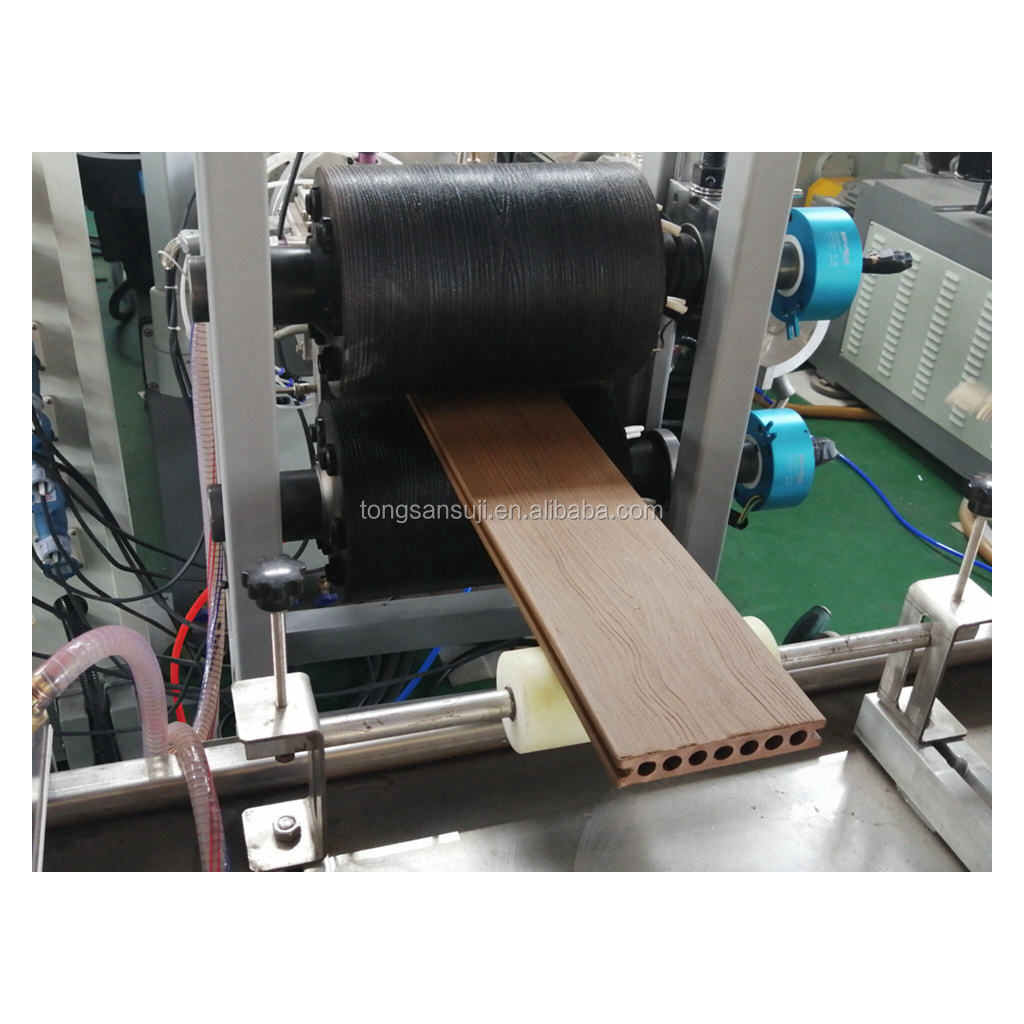

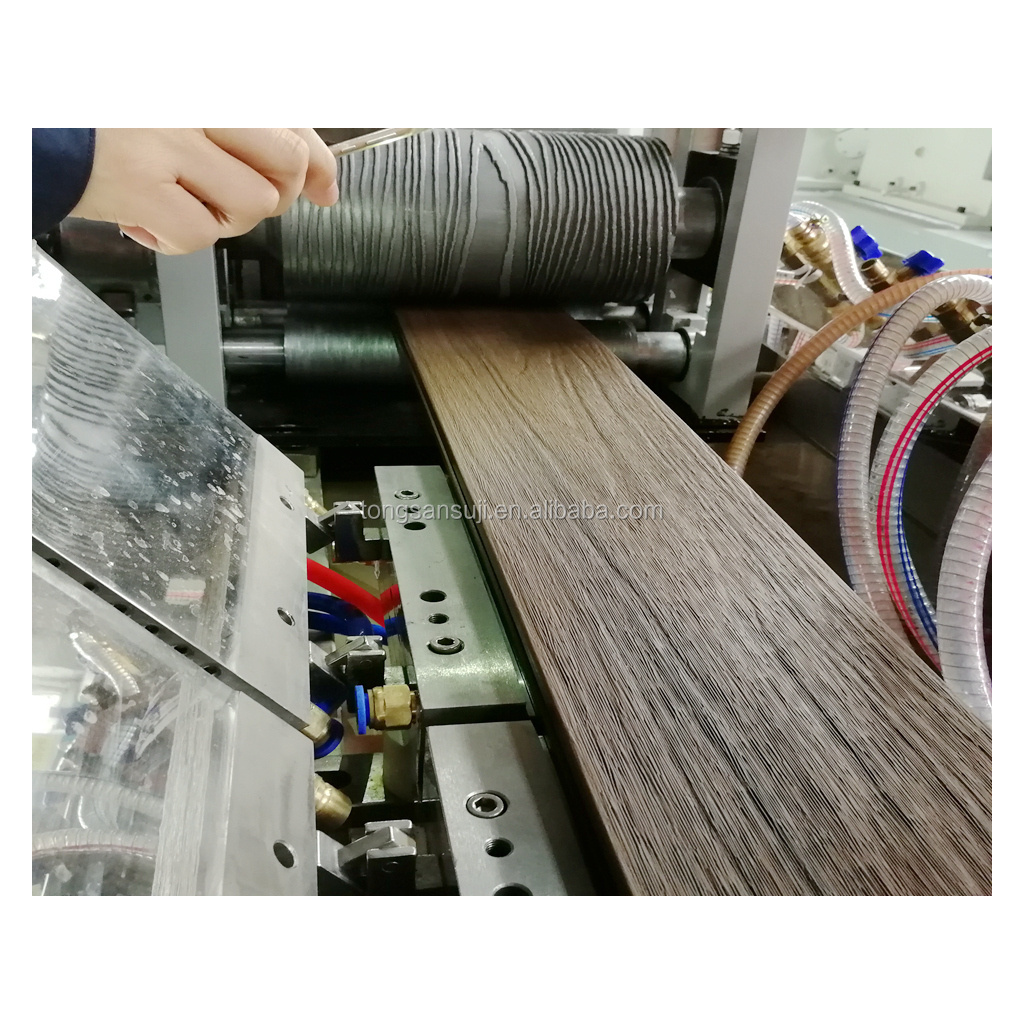

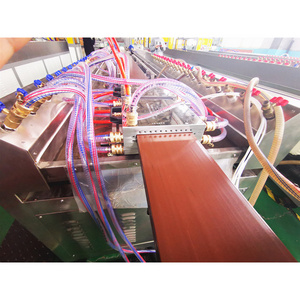

embossing:

-

wpc embossing machine

-

brushing:

-

wpc brushing machine

-

door panel:

-

wpc door production line

-

profile:

-

wpc profile machine

-

board:

-

wpc board machine

-

extrusion:

-

wpc extrusion line

-

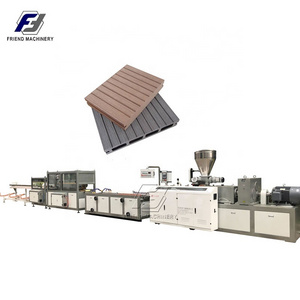

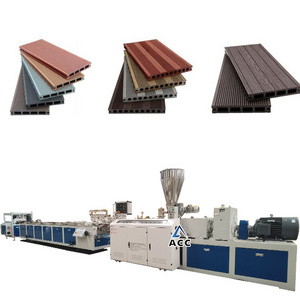

decking:

-

wpc decking machine

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Certification:

-

CE certificated

-

Output (kg/h):

-

150 - 240 kg/h

Quick Details

-

Screw Design:

-

Double-screw

-

Screw diameter (mm):

-

65 mm

-

Place of Origin:

-

Shandong, China

-

Material:

-

PE/PP/PVC,wood/rice husk/straw

-

sanding:

-

wpc sanding machine

-

embossing:

-

wpc embossing machine

-

brushing:

-

wpc brushing machine

-

door panel:

-

wpc door production line

-

profile:

-

wpc profile machine

-

board:

-

wpc board machine

-

extrusion:

-

wpc extrusion line

-

decking:

-

wpc decking machine

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Certification:

-

CE certificated

-

Output (kg/h):

-

150 - 240 kg/h

|

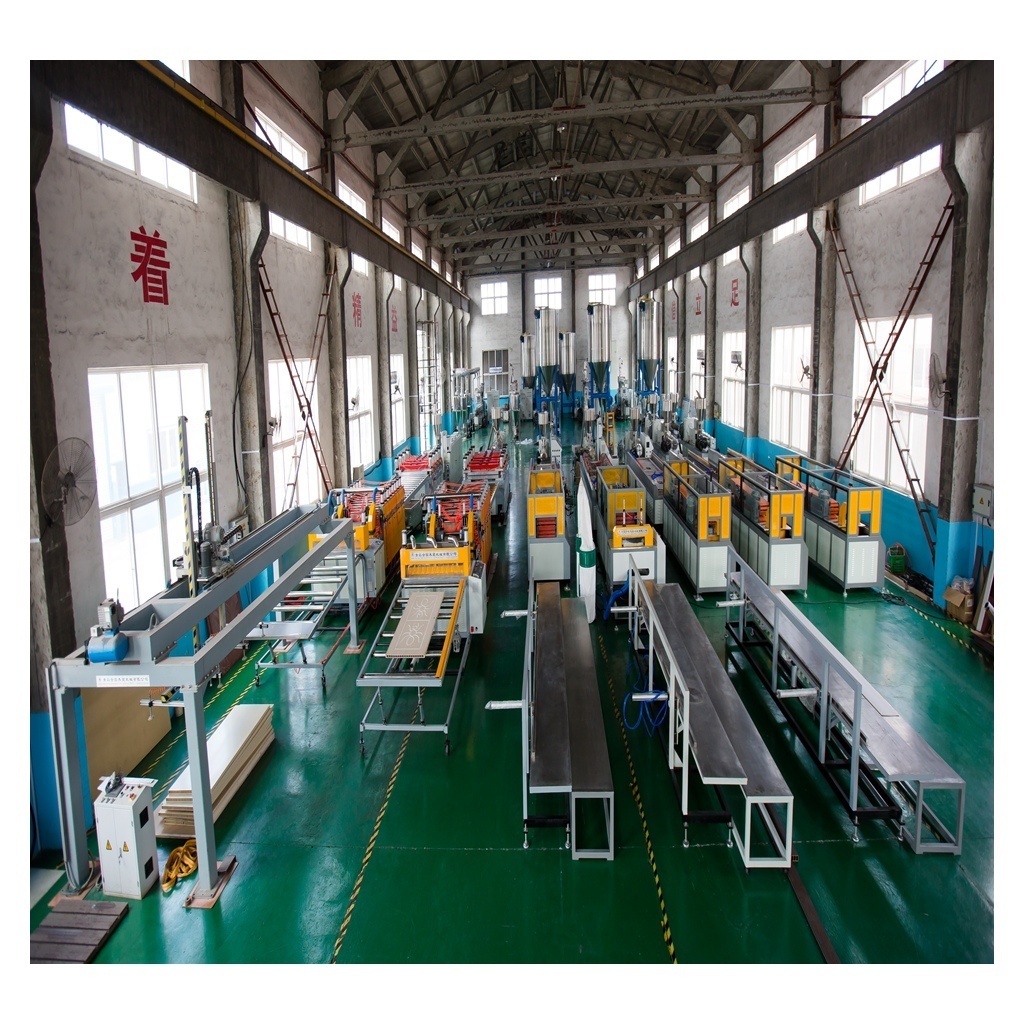

WPC plant

|

Smallest WPC plant

|

Small WPC plant

|

Medium WPC plant

|

Economic WPC plant

|

|

Approximately Production capacity (daily production for 24 hours working)

|

1200-1500kgs

|

3000-3600kgs

|

6000-7000kgs

|

9000-10000kgs

|

|

Approximately Machine cost

|

80000-130000 USD

|

130000-160000 USD

|

160000-230000 USD

|

250000-350000 USD

|

|

Suggested mini factory size

|

500 square meter

|

700 square meter

|

800 square meter

|

1200 square meter

|

|

Approximately installation power

|

200-300kw

|

300-500kw

|

400-600kw

|

500-800kw

|

Raw material for WPC manufacturing plant

|

Material

|

Mixing quantity

|

Notes

|

|

Recycled PP/PE plastic

|

25-30kgs

|

cleaned, crushed, dryer

|

|

Wood fiber material

|

50-70kgs

|

processed to 40-100mesh wood powder

|

|

Chemical additives

|

5-10kgs

|

pigments, coupling agent, lubricant, anti-UV agent, anti-oxygen agent, CaCo3

|

|

Approximately WPC material cost

|

around 0.5 USD/kg

|

according to China material cost

|

Wood Plastic Composite WPC profile machine using 70% wood fiber

1, New product: The wood-plastic is a new kind of synthetic material through the process of mixing,exruding,calibrating,hualing off and cutting,

2, Material: uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material.

3, Advantages: This kind of wood-plastic are not only very similar with natural wood in appearance and feel, but also have the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance. The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.

4, Application: The wood-plastic products are widely used in outdoor floor, close to water construction,balcony,landscape architecture,chairs and benches, fences, interior doors and windows, furniture, etc.

Production flow for wood plastic WPC decking machine

1, Preparing the material:

wood powder material:

80-100mesh wood powder, it can be made from wood sawdust, rice husk, rice straw, wheat husk and straw, cotton staw and agriculture wastage. machine need is wood crushing and pulverizer machine

plastic material:

recycled PP/PE plastic after washing and crushing into flakes. machine need is plastic washing and crushing line.

2, WPC material mixing and granulating

Mixing: put all the material into the mixing machine, such as PP/PE recycled flakes, wood powder, chemical additives

Granulating:

it is important to use a high quality granulating machine to make WPC granules, moisture exhuasting system is necessary for granulating process.

3, WPC products extrusion-molding-surface treatment

Extrusion and molding: Our conical double screw extruder is specially designed for high quality WPC products extrusion, it can make WPC material fully mixed and melted and uniform,equip with good deisgned mold and calibration, online cutting device, our Wood plastic WPC profile machine can make good WPC products, such as decking prodfiles, garden profiles, chair profiles, pergoza profiles, railing system profiles.

4, Sanding machine, brushing machine, and embossing machine

What is WPC?

The wood-plastic is a new kind of synthetic material which uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material and through the process of mixing,exrusion,calibrating,drawing off and cutting. This kind of wood-plastic materials are not only very similar with natural wood in appearance and feel,but also with the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance.The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.The wood-plastic products are widely used in outdoor floor,hydrophilic construction,balcony,landscape architecture,chairs and benches, fences, indoor doors and windows, furnitures, etc.

A mix of natural wood and plastic fiber forms wood-plastic composites. These help in reducing the overall weight of a vehicle, and in turn, it enhances its fuel efficiency. Wood plastic composites are a low-priced and eco-friendly substitute to plastic and steel components in construction applications. Hence, their demand is constantly growing in the market.

INSTALLATION AND COMMISSIONING

WE WILL SEND THE TECHNICIAN TO BUYER'S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE, AND OUR ENGINEER WILL DO TRAINNING TO BUYER'S WORKERS UNTIL THEY CAN RUN OUR MACHINE FOR STABLY PRODUCTION

AFTER SELL SERVICE: ONE YEAR GUARNTEE, FOREVER SERVICE!

WITHIN THE GUARANTEE OF ONE YEAR, WE WILL PROVIDE EFFICIENT AND ON TIME MAINTAINS,IF ANY SPARE PARTS DAMAGED IN THE GUARANTEE TERM BECAUSE OF QUALITY PROBLEM, WE WILL PROVIDE NEW SPARE PARTS FOR FREE FOR REPLACMENT.

Turnkey project service:

1, we will provide all the machines for the complete production according to customer's requirements.

2, we will provide complete service for factory layout and other informations to help customer to build the factory.

3, we can also provide the raw material to the customer if you need.

4, we will provide good service for machine installation and trainning, until the customers can run the machines and make stably production.

5, Except one year quality guarantee,we will provide after-sell service for all the life.

6, for long-term cooperation, we always provide good quality, good price and good service to customer. we are the professional and trustable supplier for turnkey projects. let us do win-win business together.

Mobile: 0086-15965573925

Skype: rosy-hegu

Alibaba: cn220187026

If any interest or questions about our machine, please feel free to contact with me.