- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JIECHUANG34

-

Design software:

-

Solidworks

-

Surface treatment:

-

Polish. Etched. Texture

-

Mould life:

-

10000 Shots

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

JIECHUANG

-

Model Number:

-

JIECHUANG34

-

Design software:

-

Solidworks

-

Surface treatment:

-

Polish. Etched. Texture

-

Mould life:

-

10000 Shots

Product Description

Our Factory

Mould Process

The principle of rotational molding of plastics is simple. Basically the process consists of introducing a known amount of plastic in powder, granular, or viscous liquid form into a hollow, shell-like mold.The mold is rotated and/ or rocked about two principal axes at relatively low speeds as it is heated so that the plastic enclosed in the mold adheres to, and forms a monolithic layer against, the mold surface. The mold rotation continues during the cooling phase so that the plastic retains its desired shape as it solidifies. When the plastic is sufficiently rigid, the cooling and mold rotation is stopped to allow the removal of the plastic product from the mold. At this stage, the cyclic process may be repeated. The basic steps of (a) mold charging, (b) mold heating, (c) mold cooling, and (d) part ejection are shown in Figure below.

Advantage

· Cost saving - Projects of 50 to 30,000 are ideal

· Molds cost less then other molding methods

· Parts offer strength and durability

· Stress free parts

· Short lead times on production

· Consistent wall thickness

· Limited materials waste

· Small to very large hollow parts can be produced

· Part surfaces can have various textures

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 35 days after confirming drawing and receive advanced payment.

Q: Do you provide samples once open mould?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% advanced payment, the balance before shippment.

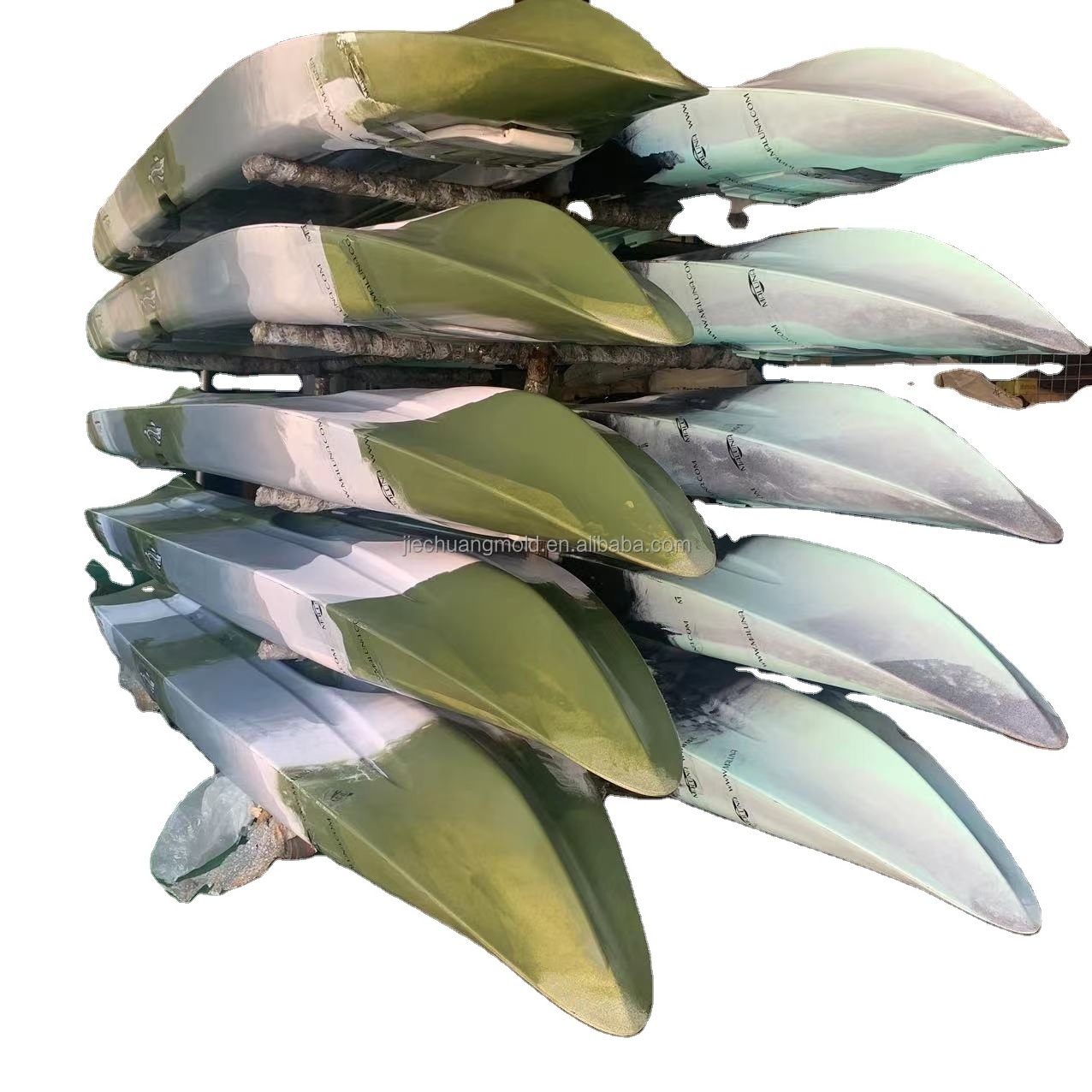

Rotomolding mold for fishing canoe kayak 2018 China

Hot Searches