- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1630*1260*1730

-

Weight:

-

600 KG

-

Model:

-

XMQL420*450

-

Application:

-

Mineral processing,mining

-

Capacity:

-

45-90KG/H

-

Feeding size:

-

5-10mm

-

Packing:

-

Exemption packing

-

Testing:

-

Before delivery

-

Keywords:

-

lab grinding mill

-

Local Service Location:

-

None

Quick Details

-

Capacity(t/h):

-

45-90

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Jinchuan

-

Dimension(L*W*H):

-

1630*1260*1730

-

Weight:

-

600 KG

-

Model:

-

XMQL420*450

-

Application:

-

Mineral processing,mining

-

Capacity:

-

45-90KG/H

-

Feeding size:

-

5-10mm

-

Packing:

-

Exemption packing

-

Testing:

-

Before delivery

-

Keywords:

-

lab grinding mill

-

Local Service Location:

-

None

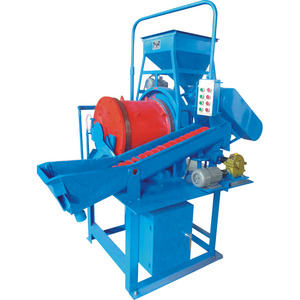

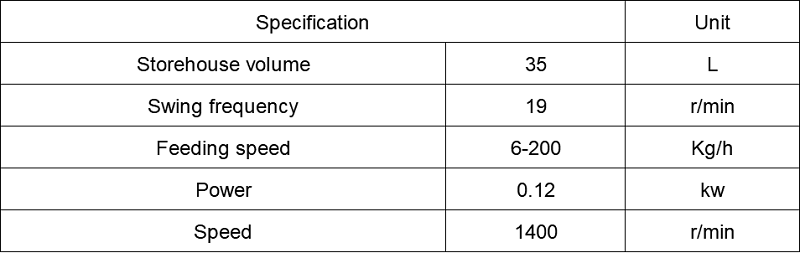

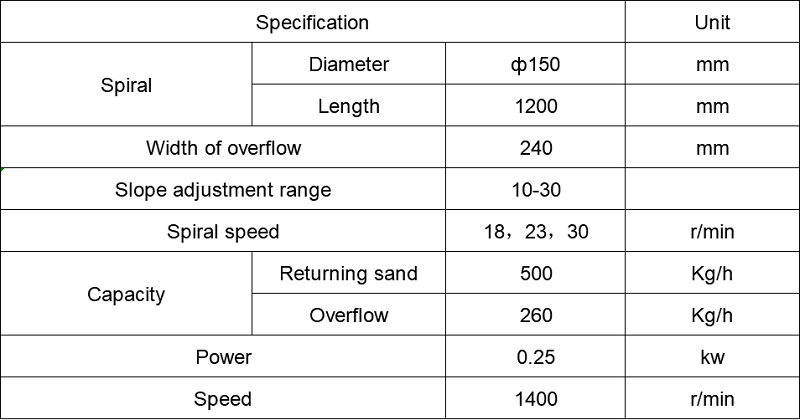

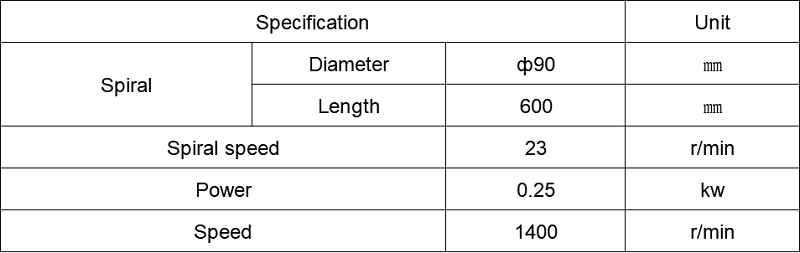

The XMQL420*450 ball Mill is mainly composed of 420×450 lattice ball mill, 150×1200 spiral classifier, 35 liter pendulum feeder and 90×600 screw conveyor, which can form continuous cutting and grinding work .The equipment install the electrical plant ane water supply system.

No additional infrastructure is required for installation. After unpacking, install the four anchor screws on the lower part of the rack ,than clean the package grease , check the lubrication, and connect the water pipe and power supply. Try driving, confirm the direction of operation, it will operate as per the sequence of operation.

Depending on the nature of the material being processed and the specific requirements for the particle size characteristics of the milled product, the following three different grinding processes can be used to grind separately:

1. Pre-grinding, inspection and grading;

2, pre-grading, returning sand and grinding;

3. Start grinding;

The XMQL420*450 ball Mill is provided for mineral processing research organization and pilot plant for continued grinding operation,and study and determination of indexes of ore grindability in tests of mineral feasibility study,It also can be provided for beneficiation plant as grinding equipment or other industries as fine material grinding equipment.The equipment include Ball Mill,Spiral Classifier,Swing Feeder,Conveyor ,optional three different processes, respectively grinding:1Pre-grinding,inspection classification 2Pre-graded sand and then back to grind 3.start grinding.

1. Check whether there are any abnormalities in each part of the equipment, whether there are obstacles in the vicinity of the equipment and rotating parts, clean up the surrounding work site, and make preparations for the equipment related to the process.

2. check the oil cup, box, bearing, supporting roller is sufficient lubricant.

3. Check whether there is any waste ore or other dirt in feeder, ball mill, classifier and screw conveyor. Use manual operation separately to see if the rotation is flexible.

4. Close the main power supply and connect the main water pipe. Start the classifier, ball mill, screw conveyor and ore feeder in order to observe whether the movement and rotation are normal. Clean the miner first, then open the water valve, wash the remaining dust and dirt rust in the ball mill, classifier and screw transportation before stopping.

5. Put the material in to the ore storage bucket.

6.According to the pre-determined solid-liquid ratio of the grinder and the fineness of the overflow of the classifier, adjust and measure the water consumption of the grinder's feeding and discharging ports.

Experienced mining machinery manufacturer for nearly 10 years

Our distinctive prodcts include shaking table, Jig, Spriral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator, electrostatic separator, vibrating screen, gold pan, feeder, classifier, ore washing machine and lab equipment ect. Our machines are popular in separating GOLD, copper, manganes, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite,ect.