- Product Details

- {{item.text}}

Quick Details

-

Pest Type:

-

Ants, Beetles, Cockroaches, Earwigs, Flies, Hornets, MOSQUITOES, SPIDERS, Termites, Borer

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Rato

-

Packing:

-

CTN

-

Material:

-

AISI 304, 316L

-

Size:

-

Customizable

-

Meet:

-

ISO9001:2008, ROHS, Food contact testing report

-

Coil pitches:

-

fixed or variable

-

Process:

-

bending, winding, end forming

-

Inlet/Outlet:

-

NPT threads,Garden hose fittings

-

Advantage:

-

High efficient, Durable

-

After Warranty Service:

-

Video technical support

-

Warranty Service:

-

Online support

-

Certification:

-

RoHS

Quick Details

-

Time Used:

-

12 hours

-

Product:

-

Mosquito-killing Tube

-

Power Source:

-

electrical

-

Pest Type:

-

Ants, Beetles, Cockroaches, Earwigs, Flies, Hornets, MOSQUITOES, SPIDERS, Termites, Borer

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Rato

-

Packing:

-

CTN

-

Material:

-

AISI 304, 316L

-

Size:

-

Customizable

-

Meet:

-

ISO9001:2008, ROHS, Food contact testing report

-

Coil pitches:

-

fixed or variable

-

Process:

-

bending, winding, end forming

-

Inlet/Outlet:

-

NPT threads,Garden hose fittings

-

Advantage:

-

High efficient, Durable

-

After Warranty Service:

-

Video technical support

-

Warranty Service:

-

Online support

-

Certification:

-

RoHS

The vapor coils are used for vapor carrying and heat transfering. By heating the tube by fire or heating-element, the heat transfered to the inside of the tube through the tube wall. We produce vapor coils in high volume every year and provide top quality at competitive price for you.

OUTSTANDING FEATURES AND ADVANTAGE:

1. We execute ISO9001 fully in the company. Besides the Quality System, we use advance quality controlling tools for our quality management and development, like APQP and SPC. You can be reassured that all of the output are meeting the standards and stable in the quality.

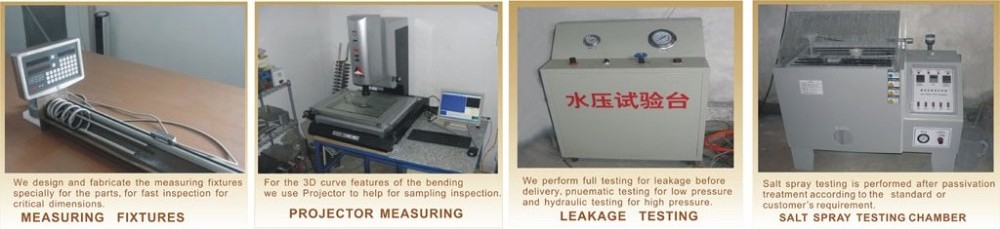

All the counterflow cooler tubes are performed testing before delivery. There is a dimensions report , material report and leakage testing report to send you before shipment.

2. With our advanced bending technology the bending and winding dimensions are precise to the drawings. The bending diameter lose is small for the counterflow cooler tube parts. The least tube ovality the tube coils provide the minimum pressure drop to the flow inside the counterflow cooler parts .

3. For the round counterflow cooler tube service , b oth the coils' diameters and the pitches can be fixed or variable. This allows you to optimize the heat transferring allocation to your system and increase the heat transferring e fficiency.

4. Different types of tube ends forming available, like beads, expansion, flaring, reduction/swage and thread cutting directly to the inlet/outlet of the tube bending parts, or welding with a fitting.

5. We also provide metalworking service like laser cutting and stamping, welding and assembly service for the counterflow cooler tube parts and its enclosure. For stainless steel material, passivation treatment is available with Salt Spray Testing Report before delivery.

6. Independent tooling design and fabrication ability is providing you the advantage of fast prototype, flexibility of your design changes, and tooling cost saving.

7. We have different type of bending machines and fixtures to meet different type of production scales, from tens of pieces to 100k pieces per month. With our tooling and technology and ability we can customize the special lines with the CNC bending machines and a series of semi-automatic bending machines for the high volume commands of counterflow cooler tube parts.

FACTORY EQUIPMENT LIST:

| NO. | EQUIPMENT | QUANTITY | APPLICATION |

| 1 | CNC Tube bending machines | 3 | tube bending |

| 2 | CNC Tube coiling machines | 5 | tube coiling |

| 3 | Sami-automatic bending machines | 6 | tube bending |

| 4 | Sami-automatic coiling machines | 8 | tube coiling |

| 5 | Tube end forming machines | 3 | flaring,swaging,expansing,beading,threading |

| 6 | Tube Cutters | 3 | tube cutting |

| 7 | Welding machines | 5 | welding for fittings and tanks |

| 8 | Ultrasonic cleaner | 1 | cleaning and passivation |

| 9 | Projector Measuring Machine | 1 | samples inspection |

| 10 | Pneumatic Testing Station | 1 | Leakage Testing |

| 11 | Hydraulic Testing Station | 1 | Leakage Testing |

| 12 | Salt Spray Testing Chamber | 1 | Surface Corrosion Testing |

QUALITY CONTROLLING:

OUR FACILITIES:

PACKAGING AND STORAGE OF OUR PARTS:

copper cooler tube copper cooler tube copper cooler tube copper cooler tube copper cooler tube copper cooler tube copper cooler tube copper cooler tube copper cooler tube copper cooler tube

![[BLUEDRA] famous Electric Insect Fogger for Killing and pest control fumigation mini fogging machine Portable Fogger Sprayer](https://cdn.bestsuppliers.com/seo_products_img/kr1558035493wktj/f0c40b8de8cd3045afa7faf217a07f5e.jpg!/rotate/180/sq/300)