- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DZX

-

Model Number:

-

0Cr21Al6Nb, 0Cr21Al6Nb

-

Rated voltage:

-

standard

-

Color:

-

Bright, Acid white, Oxidated

-

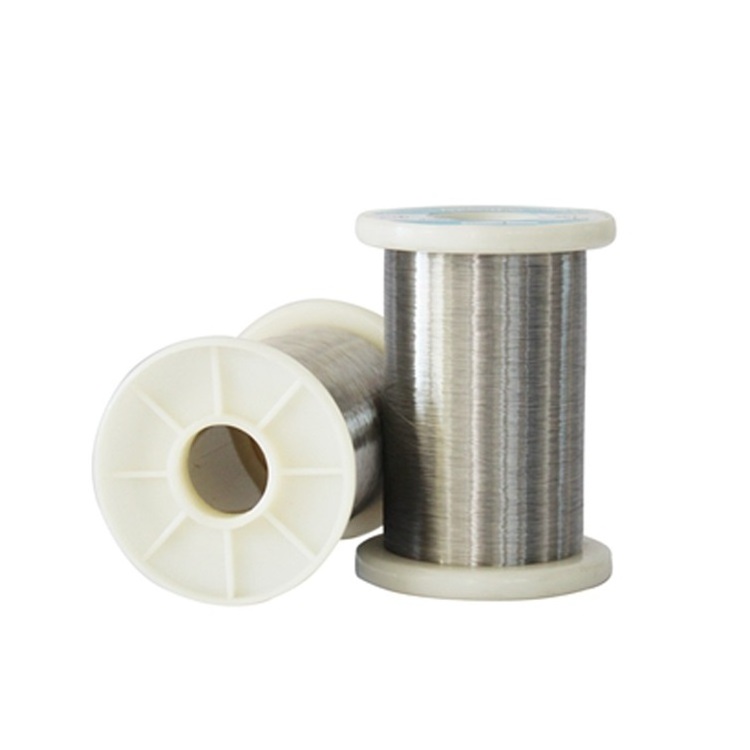

Shape:

-

Round wire, flat wire, rod, strip

-

Resistivity:

-

1.45

-

Density:

-

7.1

-

Tensile strength:

-

650-800

-

Elongation at rupture:

-

>12

-

Melting point:

-

1510℃

-

Feature:

-

High resistivity, good anti-oxidation and anti-corrosion

Quick Details

-

Application:

-

Heating

-

Conductor Material:

-

Aluminum

-

Conductor Type:

-

Solid

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DZX

-

Model Number:

-

0Cr21Al6Nb, 0Cr21Al6Nb

-

Rated voltage:

-

standard

-

Color:

-

Bright, Acid white, Oxidated

-

Shape:

-

Round wire, flat wire, rod, strip

-

Resistivity:

-

1.45

-

Density:

-

7.1

-

Tensile strength:

-

650-800

-

Elongation at rupture:

-

>12

-

Melting point:

-

1510℃

-

Feature:

-

High resistivity, good anti-oxidation and anti-corrosion

Products Description

Fechral Aluchrom-O 0cr23al5 OCr23AL5 Heating Element Wire Electric Resistance Alloy for Heater

0cr23al5 is one kind of normal material of Fe-Cr-Al alloy.

FeCrAl alloy has the characteristic of high resistivity,low temperature resistance coefficient,high operating temperature,goodanti-oxidation and anti-corrosion under high temperature.

It is widely used in industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive,

military and other industries producing heating elements and resistance elements.

FeCrAl alloy has the characteristic of high resistivity,low temperature resistance coefficient,high operating temperature,goodanti-oxidation and anti-corrosion under high temperature.

It is widely used in industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive,

military and other industries producing heating elements and resistance elements.

Specification

|

Alloy Nomenclature Performance

|

|

1Cr13AL4

|

0Cr25Al5

|

0Cr21AL6

|

0Cr23Al5

|

0Cr21Al4

|

0Cr21Al6Nb

|

0Cr27Al7Mo2

|

|

|

Main Chemical composition |

Cr

|

12.0-15.0

|

23.0-26.0

|

19.0-22.0

|

20.5-23.5

|

18.0-21.0

|

21.0-23.0

|

26.5-27.8

|

|

|

|

Al

|

4.0-6.0

|

4.5-6.5

|

5.0-7.0

|

4.2-5.3

|

3.0-4.2

|

5.0-7.0

|

6.0-7.0

|

|

|

|

Re

|

opportune

|

opportune

|

opportune

|

opportune

|

opportune

|

opportune

|

opportune

|

|

|

|

Fe

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

|

|

|

|

|

|

|

|

|

Nb0.5

|

Mo1.8-2.2

|

|

|

Max. continuous service temp. of element(°C)

|

|

950

|

1250

|

1250

|

1250

|

1100

|

1350

|

1400

|

|

|

Resistivity at 20ºC(μΩ·m)

|

|

1.25

|

1.42

|

1.42

|

1.35

|

1.23

|

1.45

|

1.53

|

|

|

Density(g/cm3)

|

|

7.4

|

7.1

|

7.16

|

7.25

|

7.35

|

7.1

|

7.1

|

|

|

Thermal conductivity(KJ/m·h·ºC)

|

|

52.7

|

46.1

|

63.2

|

60.2

|

46.9

|

46.1

|

--

|

|

|

Coefficient of lines expansion(α×10-6/ºC)

|

|

15.4

|

16

|

14.7

|

15

|

13.5

|

16

|

16

|

|

|

Melting point approx.( ºC)

|

|

1450

|

1500

|

1500

|

1500

|

1500

|

1510

|

1520

|

|

|

Tensile strength(N/mm2)

|

|

580-680

|

630-780

|

630-780

|

630-780

|

600-700

|

650-800

|

680-830

|

|

|

Elongation at rupture(%)

|

|

>16

|

>12

|

>12

|

>12

|

>12

|

>12

|

>10

|

|

|

Variation of area(%)

|

|

65-75

|

60-75

|

65-75

|

65-75

|

65-75

|

65-75

|

65-75

|

|

|

Repeat Bending frequency(F/R)

|

|

>5

|

>5

|

>5

|

>5

|

>5

|

>5

|

>5

|

|

|

Hardness(H.B.)

|

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

200-260

|

|

|

continuous service time(Hours/ ºC)

|

|

--

|

≥80/1300

|

≥80/1300

|

≥80/1300

|

≥80/1250

|

≥50/1350

|

≥50/1350

|

|

|

Micrographic structure

|

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

Ferrite

|

|

|

Magnetic properties

|

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

Magnetic

|

|

|

Shape

|

Size(mm)

|

|

|

|

Wire

|

0.05-7.50

|

|

|

|

Rod

|

8-50

|

|

|

|

Ribbon

|

(0.05-0.35)*(0.5-6.0)

|

|

|

|

Strip

|

(0.5-2.5)*(5-180)

|

|

|

Widely Use

Recommend Products

About Us

JIANGSU DZX TECHNOLOGY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire,strip, ribbon, bar, tube, plate.

Customized service

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Hot Searches