- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

customzied

-

Output product name:

-

tomato paste,tomato ketchup,tomato sauce

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field maintenance and repair service

-

Machine structure:

-

High quality stainless steel SUS304 and SUS316L

-

Operation mode:

-

Full automatic PLC, touch screen

-

Package:

-

aseptic carton box ,bottle,plastic bag,etc

-

End product:

-

paste,juice,sauce

-

Filling mathod:

-

carton box, tin can,bottle,sachat bag

-

Name:

-

big bag filling machine

-

Product name:

-

tomato sauce making machine

-

Certification:

-

CE ISO

Quick Details

-

Brand Name:

-

JIMEI

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220V380V

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

customzied

-

Output product name:

-

tomato paste,tomato ketchup,tomato sauce

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field maintenance and repair service

-

Machine structure:

-

High quality stainless steel SUS304 and SUS316L

-

Operation mode:

-

Full automatic PLC, touch screen

-

Package:

-

aseptic carton box ,bottle,plastic bag,etc

-

End product:

-

paste,juice,sauce

-

Filling mathod:

-

carton box, tin can,bottle,sachat bag

-

Name:

-

big bag filling machine

-

Product name:

-

tomato sauce making machine

-

Certification:

-

CE ISO

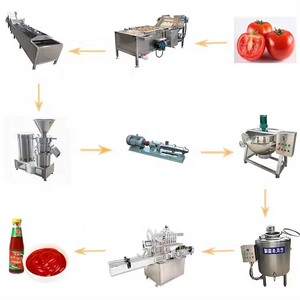

Tomato paste proudction line production process:

The raw material selection, washing, dressing, blanching, pulping, heating and concentrating, canning, sealing and sterilization - cooling - finished products.

|

capacity per hour

|

raw material

|

Packing way

|

|

from 1T to 30 T each hour

|

fresh tomato

|

Tin can

|

Fresh tomatoes arriving at the plant in trucks are unloaded into a collection channel (also known as flume), a stainless steel or cement duct into which a quantity of water 3 to 5 times higher than the amount of unloaded tomato is continuously pumped. For example, a 10 tons/hour rate requires at least 30m3/hour of water.

This water flow carries the tomatoes into the roller elevator, which then conveys them to the sorting station. The delivery trucks park-up alongside the flume and, while the trailers containing the tomatoes are being tilted towards it, an operator, using a special tube, pipes a vast quantity of water inside the truck, so that the tomatoes can flow out from the special 50 x 50cm opening. In this way the tomatoes and the water will be gradually feed into the flume without getting damaged.

The tomatoes then arrive at the sorting station, after having been rinsed under a clean water spraying system (preferably drinking water). Here the staff removes the green, damaged and excessively small tomatoes which are placed on a reject conveyor (or an auger) and then collected in a large box or directly inside a truck to be taken away. The tomatoes suitable for processing are transported to the chopping station (this may be a hammer mill or a special mono-pump provided with pre-feeding screw) where they are chopped. The pulp is pre-heated to 65-75°C for Cold Break processing or to 85-95°C for Hot Break processing. The main control panel on the evaporator regulates the pre-heating temperature.

The heated tomato pulp (fiber, juice, skin and seeds) is then conveyed via a special pump to an extraction unit composed of two operating stations: a pulper and a refiner, equipped with two sieves having different sized meshes. The first sieve processes solid pieces up to 1 mm, while the refiner processes solid pieces up to 0.6 mm, depending on the type of sieve fitted on the machine (the manufacturer can supply sieves with different sized holes if necessary). Two products therefore come out of the extraction unit: refined juice for concentration and waste for disposal. The average extractor yield varies according to different factors: the pulp’s temperature (a higher temperature will mean an increased juice yield), the variety of tomatoes treated, the type of sieve fitted, the rotation speed and the shape of the rotor on each dejuicing body unit. On average, however, the yield is about 95%. For example, if the extractor is fed with 100 kg of hot pulp, it will produce 95 kg of juice and 5 kg of waste. In addition, there is also a hypothetical product waste of about 1-3% from the grading stations. Therefore, 100 kg of tomatoes unloaded from the trucks will produce about 93-94 kg of juice to be concentrated. At this point the refined juice is collected in a large tank which constantly feeds the evaporator. This tank is equipped with maximum and minimum level indicators-adjusters which control the pump supplying juice to the evaporator.

The juice in this storage tank is fed to the evaporator which automatically regulates juice intake and finished concentrate output; the operator only has to set the Brix value on the evaporator’s control panel; during normal working conditions, the evaporator does not require any further regulations. The juice inside the evaporator passes through different stages (also called effects) where its concentration level will gradually increase until the required density is obtained in the final stage or “finisher”. Here the tomato paste is automatically extracted via a pump controlled by an electronic refractometer.

The entire concentration process (evaporation) takes place under vacuum conditions and at low temperatures, significantly below 100°C. Product circulation inside the various concentric tubular exchangers is carried out by special stainless steel pumps which are designed to ensure that the product is conveyed inside the exchanger tubes at a speed of over 1.2 m/sec to avoid “flash evaporation” thus avoiding to get burnt.