- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

NEWGOER

-

Model Number:

-

NG-707

-

Material:

-

304 Stainless Steel

-

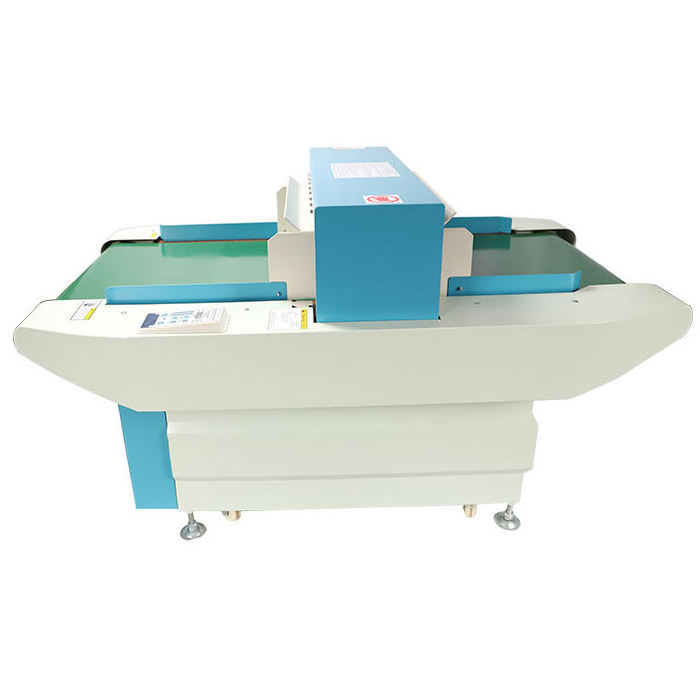

Size:

-

235*110*115 cm

-

Sensitivity adjustment:

-

1-10 Degree

-

Detection sensitivity:

-

0.8-2.0mm Iron Ball

-

Detect Method:

-

Magnetic induction

-

Alarm method:

-

Beep, light

-

Detection width:

-

600mm

-

Detection height:

-

100-250mm (or CUSTOM)

-

Application:

-

garment, textile, bra, baby product, shoes, socks, gloves

-

Product name:

-

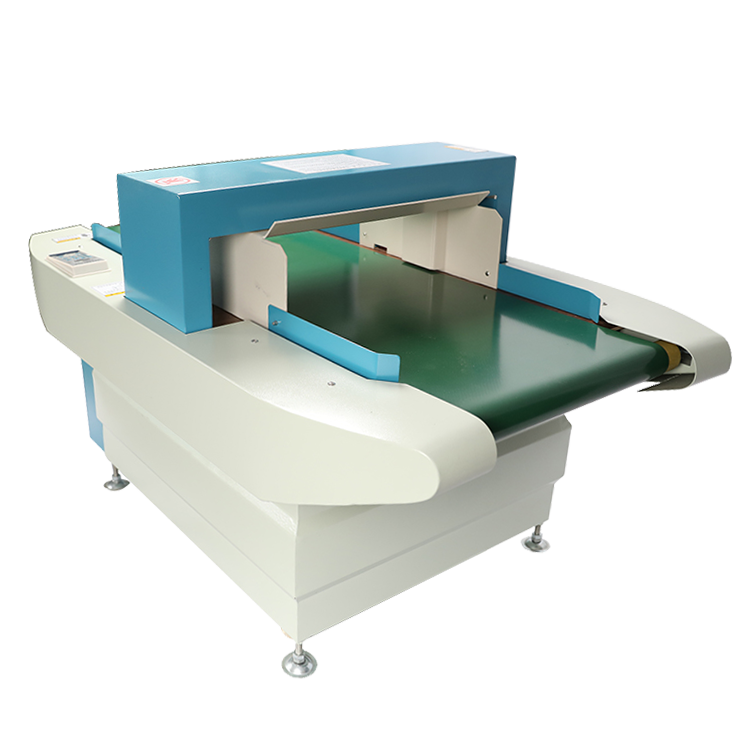

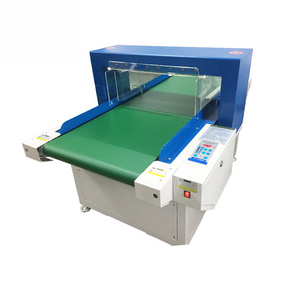

High Sensitivity Conveyor Belt Needle Detector

-

Function:

-

detect metals, separating metals

-

Power supply:

-

220v 50/60HZ

-

Power:

-

Electric Power

Quick Details

-

Warranty:

-

18 Months

-

Type:

-

Needle detector machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NEWGOER

-

Model Number:

-

NG-707

-

Material:

-

304 Stainless Steel

-

Size:

-

235*110*115 cm

-

Sensitivity adjustment:

-

1-10 Degree

-

Detection sensitivity:

-

0.8-2.0mm Iron Ball

-

Detect Method:

-

Magnetic induction

-

Alarm method:

-

Beep, light

-

Detection width:

-

600mm

-

Detection height:

-

100-250mm (or CUSTOM)

-

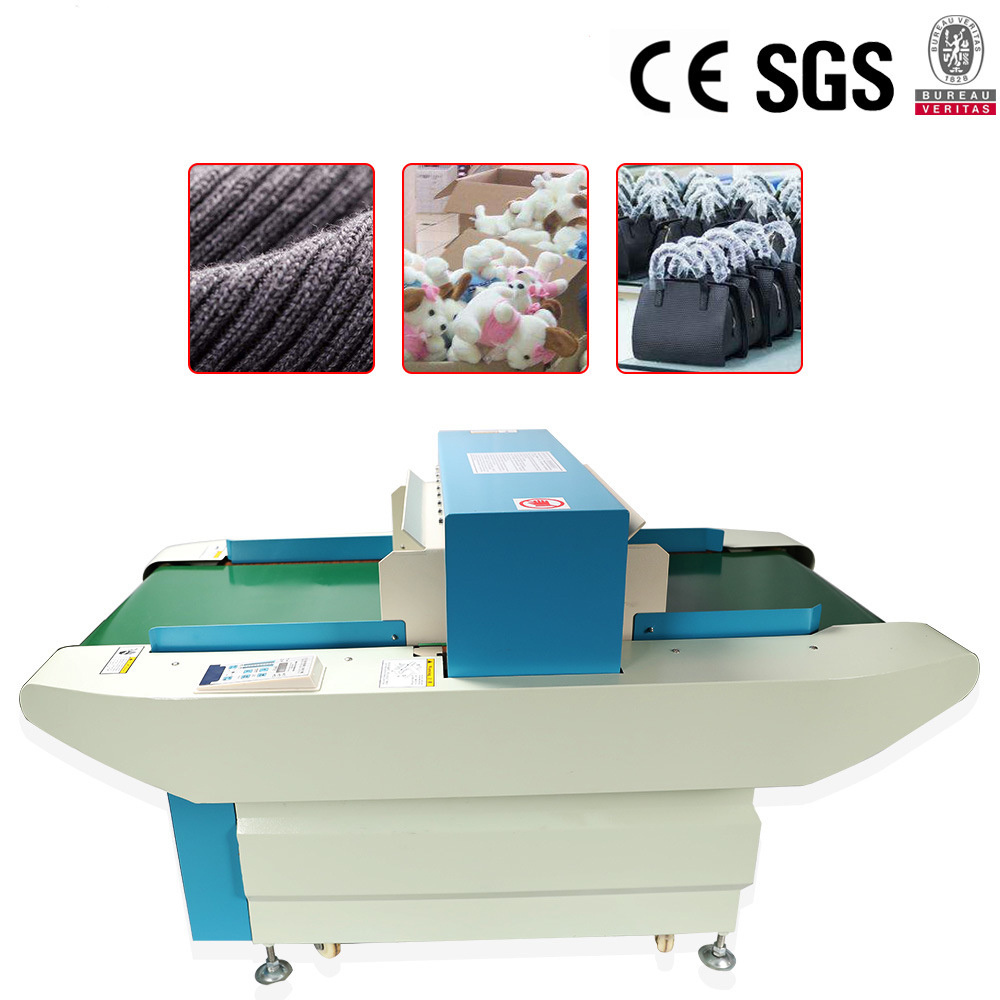

Application:

-

garment, textile, bra, baby product, shoes, socks, gloves

-

Product name:

-

High Sensitivity Conveyor Belt Needle Detector

-

Function:

-

detect metals, separating metals

-

Power supply:

-

220v 50/60HZ

-

Power:

-

Electric Power

Product Description

Best Selling Textile Needle Detector

Conveyor Belt

Broken Needle Detector for Clothes Processing Industry

Summary:

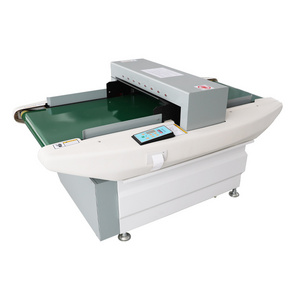

Needle Metal Detector Machine used mainly for food and other requirements of high detection sensitivity industries, for the detection of inclusions or lost in the raw materials or products of Broken Needle, wire or lead, copper, aluminum, tin, stainless steel and other metals. Detection lost pin and scrap iron kind of impurities in the products, provide reliable product quality assurance. With stable performance and precision detecting function, can keep your product and customer safe, thus protect your brands.

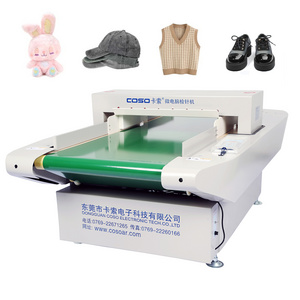

Applicable Industries: garment, textile, bra, baby product, shoes, socks, gloves and so on, for detecting impurities such as needle points, pins and scrap iron in products, preventing metal pollution of the products and guaranteeing product quality.

Needle Metal Detector Machine used mainly for food and other requirements of high detection sensitivity industries, for the detection of inclusions or lost in the raw materials or products of Broken Needle, wire or lead, copper, aluminum, tin, stainless steel and other metals. Detection lost pin and scrap iron kind of impurities in the products, provide reliable product quality assurance. With stable performance and precision detecting function, can keep your product and customer safe, thus protect your brands.

Applicable Industries: garment, textile, bra, baby product, shoes, socks, gloves and so on, for detecting impurities such as needle points, pins and scrap iron in products, preventing metal pollution of the products and guaranteeing product quality.

|

Item

|

NG-707

Metal Needle Detector Machine

|

|

Detection method

|

Magnetic induction

|

|

Sensitivity adjustment

|

1-10 Degree

|

|

Detection sensitivity

|

0.8-2.0mm Iron Ball

|

|

Alarm method

|

Beep, light

|

|

Detection width

|

600mm

|

|

Detection height

|

100-250mm (Or customize)

|

|

Power consumption

|

120W

|

|

Voltage

|

220V/50~60Hz

|

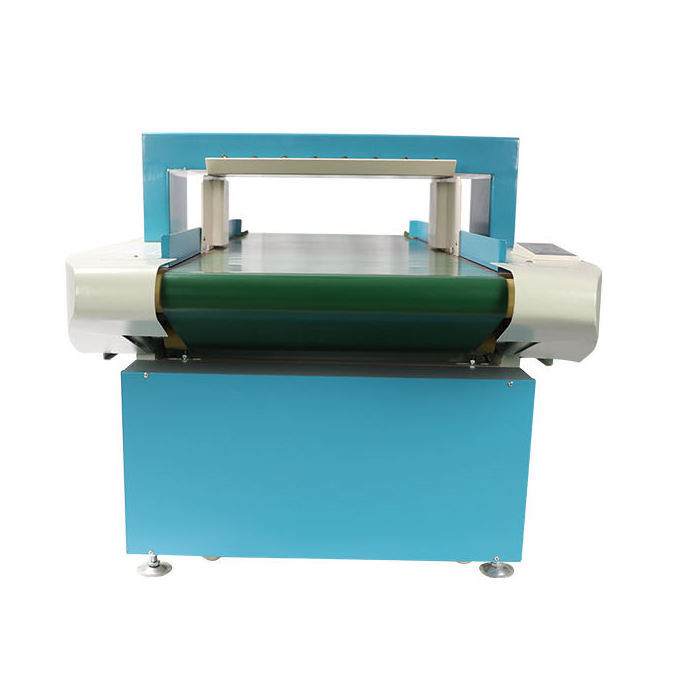

Features:

1.Branded computer chip, dual-frequency integrated circuit, cross magnetic induction detection, bring with higher accuracy, reliability and stability.

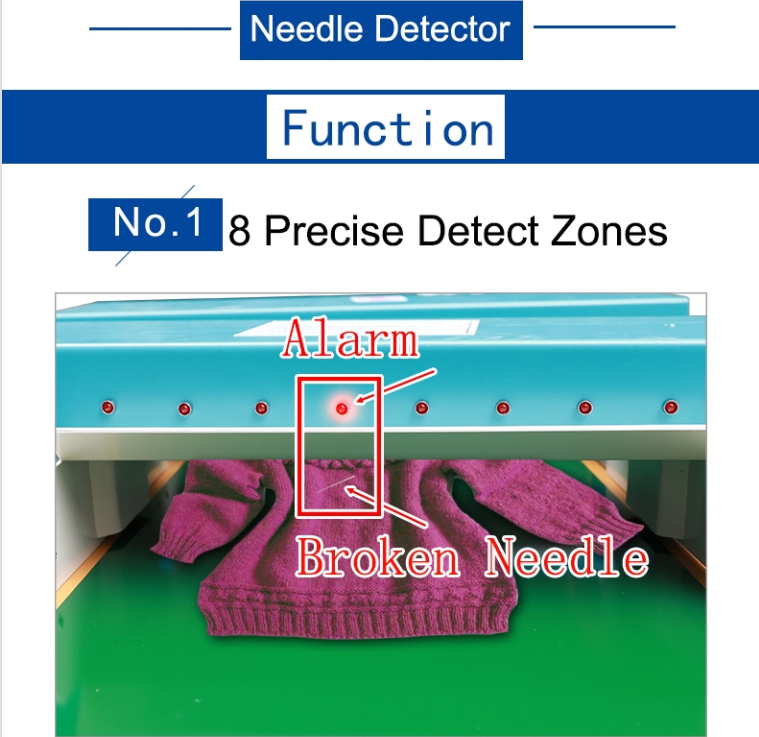

2.Automatic control system and uses special magnetic sensitive materials and unique technology, the detection accuracy of the needle detector is particularly high, and the exact needle-breaking position is displayed into 8 detecting zones.

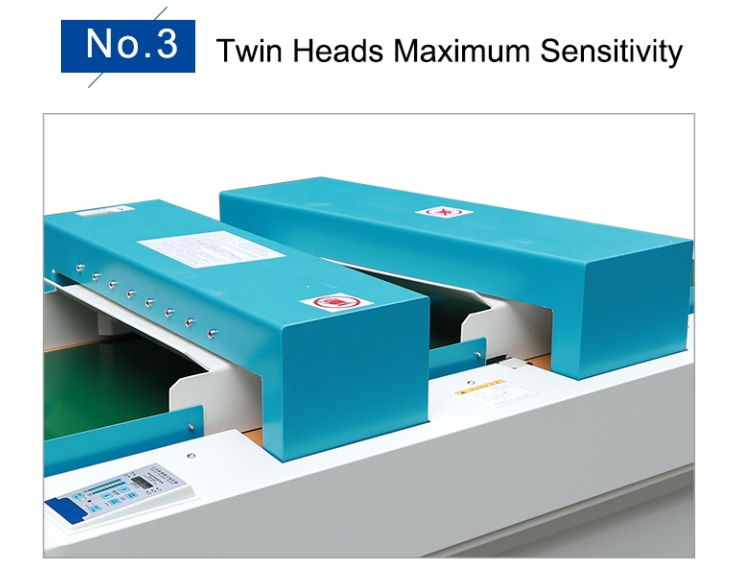

3.Twin search heads design, double detection function, higher safety performance, compared with other types of needle detectors, at the same detection height, the sensitivity is increased by 10%.

4.Automatic detection, automatic induction, automatic stop when no detection is needed, 0-10 sensitivity degree adjustment, when there is a broken needle, the conveyor belt automatically stops and returns backwards.

5.With counting function, it can count the number of qualified or defective products.

6.It has two alarm modes: sound effect and light alarming.

7.Luxury appearance, novel style, saving time and electricity, simple operation

1.Branded computer chip, dual-frequency integrated circuit, cross magnetic induction detection, bring with higher accuracy, reliability and stability.

2.Automatic control system and uses special magnetic sensitive materials and unique technology, the detection accuracy of the needle detector is particularly high, and the exact needle-breaking position is displayed into 8 detecting zones.

3.Twin search heads design, double detection function, higher safety performance, compared with other types of needle detectors, at the same detection height, the sensitivity is increased by 10%.

4.Automatic detection, automatic induction, automatic stop when no detection is needed, 0-10 sensitivity degree adjustment, when there is a broken needle, the conveyor belt automatically stops and returns backwards.

5.With counting function, it can count the number of qualified or defective products.

6.It has two alarm modes: sound effect and light alarming.

7.Luxury appearance, novel style, saving time and electricity, simple operation

Related Products

Company Introduction

Certifications

Our customers

FAQ

1.Are your company a trading one or a factory ?

Factory + trade (integration), 20 years focusing on test instruments field, 6 years exporting experience.

OEM is also acceptable for us.

2.How to choose the most suitable products?

Our professional team will give you the best suggestion as long as you tell us what kind of test you

need to do and the required specification.

3.What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20

working days after deposit receipt. If you are in urgent need, we can consider making special

arrangement for you.

4.Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to

your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

5.Can we visit your factory before order?

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to

arrange hotel and pick up you from airport.

Our Services

Contact Us

Hot Searches