- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220V/380V/440V or local need

-

Dimension(L*W*H):

-

5900*2200*2400mm

-

Weight (KG):

-

4800 kg

-

Keywords:

-

brick making machinery

-

COLOR:

-

Customizable

-

Power supply:

-

Electric

-

Manufacturer:

-

Hongfa factory

-

Leveling:

-

Automatic Self-leveling

-

Main market:

-

Africa and Southeast Asia

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO9001/CE

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

5800-7700pcs/8h for hollow block

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220V/380V/440V or local need

-

Dimension(L*W*H):

-

5900*2200*2400mm

-

Weight (KG):

-

4800 kg

-

Keywords:

-

brick making machinery

-

COLOR:

-

Customizable

-

Power supply:

-

Electric

-

Manufacturer:

-

Hongfa factory

-

Leveling:

-

Automatic Self-leveling

-

Main market:

-

Africa and Southeast Asia

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO9001/CE

Product Description

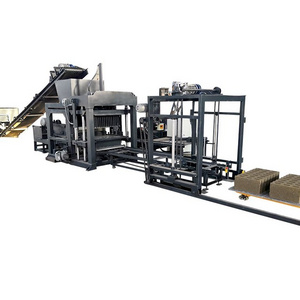

QT4-15D Concrete Block, Paver & Curbstone making machine

Brief introduction

1.The machine adopts hydraulic system and the working procedure is very even and dependable, hydraulic press together with efficiently vibration make the shape, it which has high density and good quality.

2.It is a practical machine that simple in structure, artistic in figure. Especially suitable to the production of the standard bricks, it can produce various kinds of paving bricks, porous bricks, roads bricks etc.

3.The reasonable material proportion have the capacity of making high-density standard bricks, what’s more, it can be piled up directly.

Control system

PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple trained one to the operator. Product scope: It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock linkage blocks, road curb bricks, hydraulic blocks、hollow blocks, perforated bricks, and standard bricks etc.

Productivity

|

NO.

|

Item

|

Size(mm)

|

PCS/mold

|

PCS/8 hour

|

|

1

|

hollow block

|

400*200*200

|

4

|

5800-7700

|

|

2

|

solid brick

|

240*115*53

|

28

|

47500-53600

|

|

3

|

paving brick

|

220*110*50

|

16

|

18500-23000

|

Specification

Brick making machinery QT4-15D Technical Parameter

1. Overall dimension:7100*1600*2610mm

2. Mian vibration form: Platform virbraiton

3. Vibration frequency:4600(r/min)

4. Molding cycle:15-25s

5. Motors power:27.5kw

2. Mian vibration form: Platform virbraiton

3. Vibration frequency:4600(r/min)

4. Molding cycle:15-25s

5. Motors power:27.5kw

Raw material of QT4-15D Brick making machinery

Raw material :crushed stone, cement, cinder, slag, sand,clay,gangue, perlite,coal fly ash and other industrial wastes.

Prices of china automatic hollow block moulding machine brick making machinery in ghana

It can produce not only hollow block, but also curbstone, color paving brick etc,just need to change the molds.

Packing & Delivery

Standard Marine packing or according to customer's requirements

.

Our service:

Pre-sales Service

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory,

feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line anytime.

(5) Introduce the company file, product categories and production process.

(6)Sample testing support.

In Sale

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale

(1) Training how to instal the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly ,get feedback in time,keep well communication with each other

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory,

feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line anytime.

(5) Introduce the company file, product categories and production process.

(6)Sample testing support.

In Sale

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale

(1) Training how to instal the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly ,get feedback in time,keep well communication with each other

Hot Searches