- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

wellmark

-

Model Number:

-

GS301

-

Type:

-

Glue Stick, glue stick

-

Product name:

-

Hotmelt Adhesive

-

Certificate:

-

TDS

-

Application:

-

Packing Industry

-

Package:

-

Customized Package

-

Shelf life:

-

12 Months

-

Function:

-

Gluing

-

Application range:

-

Paper Box

Quick Details

-

CAS No.:

-

none

-

Other Names:

-

Hot Glue tick

-

MF:

-

none

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

wellmark

-

Model Number:

-

GS301

-

Type:

-

Glue Stick, glue stick

-

Product name:

-

Hotmelt Adhesive

-

Certificate:

-

TDS

-

Application:

-

Packing Industry

-

Package:

-

Customized Package

-

Shelf life:

-

12 Months

-

Function:

-

Gluing

-

Application range:

-

Paper Box

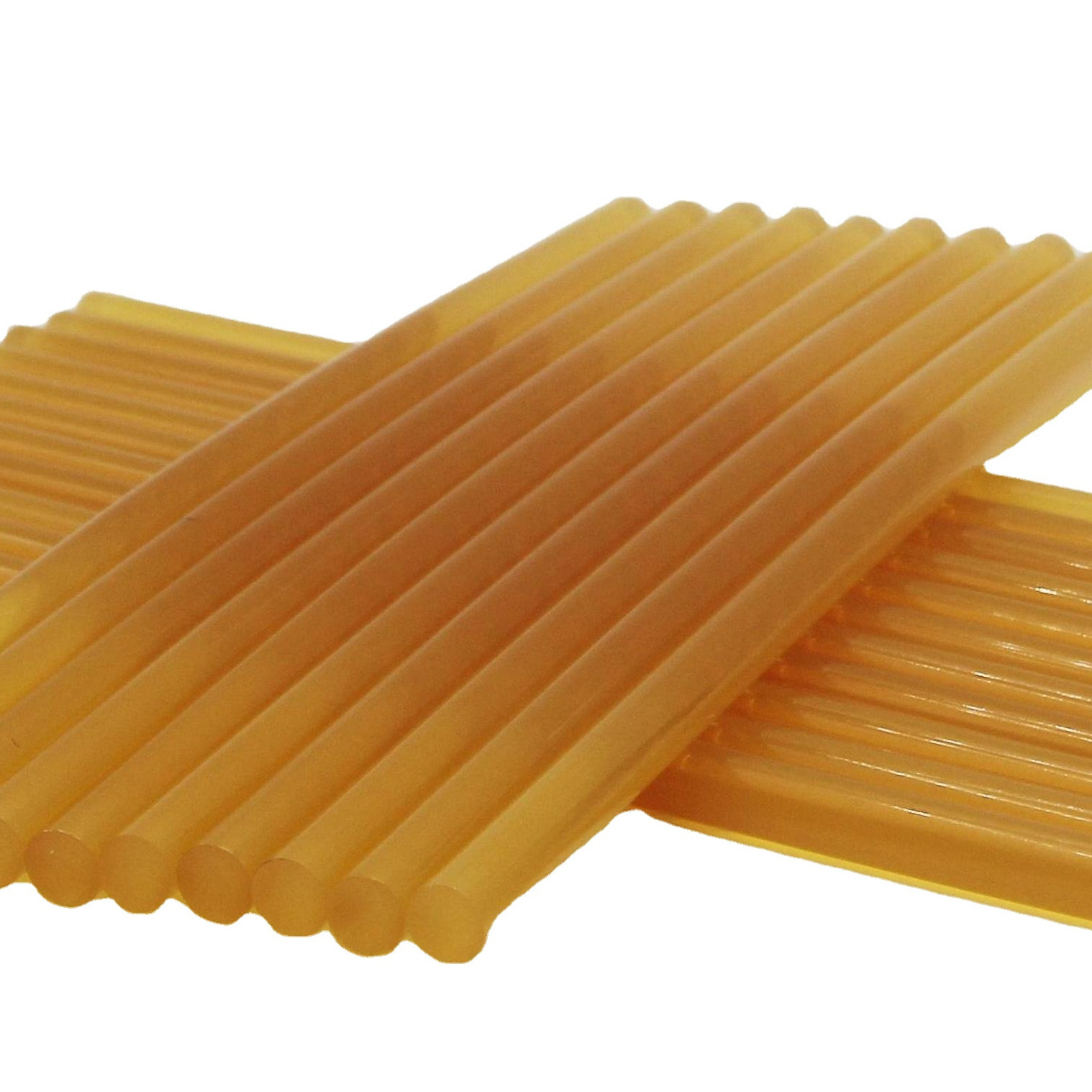

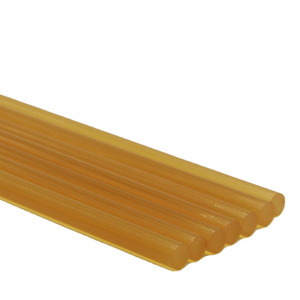

Hot Melt Glue Stick / Rubber stick

Product Features

Hot Melt Adhesive Bar Non - toxic, easy to operate, continuous use without carbonization with fast bonding, high strength, aging resistance, non - toxic, thermal stability, film toughness and other characteristics. The shape has rod, granular. Hot melt adhesive bar is a solid adhesive made of ethylene - vinyl acetate copolymer (EVA) as the main material, adding viscosity and other components.

Operational Approach

Hot melt Adhesives Bar stick with glue gun use, hot melt glue gun glue, put the glue stick into the hot melt gun, plug in the heat for a while, pull the trigger gun muzzle will have glue out. Also can use lighter to melt hot glue stick end to burn directly, besmear in the place that wants to stick, stick good wait for glue to become solid go. Bonded paper carton, crafts, handmade, and so on, both convenient and easy to use, than the general glue bonding firm.

Product Application

Applied to plastic, metal, wood, paper, toys, electronics, furniture, leather, crafts, shoe materials, coating, ceramic, lamp shade, pearl cotton, food packaging, speakers and other bonding, hot melt glue gun, hot melt glue machine.

Workmanship

1. Weigh the raw materials according to the formula ratio of hot melt glue bar and add them into the reaction kettle. Heat to melt and stir evenly. Then the melted rubber in the reaction kettle is cooled to a certain temperature and put into the running extruder. The extrusion speed of the extruder can be selected according to the different types of rubber. The hot melt adhesive extruder by extrusion head of a trapped shape extruding hole to squeeze into the sink, hot melt adhesive in cooling water immediately setting, glue stick through the first preliminary cooling of the cooling water tank shapes, through tractor traction to enter the second cooling water tank, in the second cooling water tank colloid fully cooling stereotypes, glue stick in the sink running speed controlled by extruder extrusion speed, let the tractor traction speed and extruder extrusion speed synchronization.

2. Adjust and control the relationship between extrusion speed, cooling setting speed and traction speed, and then cut and box the cooled glue rods into finished products.

Main Parameter

| color | Shear strength | Peel strength | viscosity | Softening Temperature | Curing time | Operating temperature | storage life |

| Light Yellow | 3MPa-8MPa | 50N/cm-150N/cm | 5300cps | 65-135℃ | 8-10 seconds | 160-180℃ |

12 Months |