- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

2

-

Weight (KG):

-

110

-

Product name:

-

Solder Dross Recovery Machine

-

Usage:

-

Tin slag recycling

-

Separation rate:

-

93.6%

-

Color:

-

Silver

-

Advantage:

-

High-cost efficiency

-

Final Product:

-

Tin brick

-

After Warranty Service:

-

Video technical support, Online support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gomine

-

Marketing Type:

-

New Product 2022

-

Power (kW):

-

2

-

Weight (KG):

-

110

-

Product name:

-

Solder Dross Recovery Machine

-

Usage:

-

Tin slag recycling

-

Separation rate:

-

93.6%

-

Color:

-

Silver

-

Advantage:

-

High-cost efficiency

-

Final Product:

-

Tin brick

-

After Warranty Service:

-

Video technical support, Online support

Film waste carton compressed plastic bottle can pressing machine hydraulic press and baling machine

Product Description

Solder Dross Separation Machine is an endeavor in reverting and recycling the oxides which occur during working of a Wave Soldering Machine in order to reduce production cost, create a greener environment and assist the quality process.

Solder dross separator for slag solder wave solder recycling,

GM-SD10

model with small size,manually put tin,with tin car,PCB manufacturers use solder recycling machine to recycle solder onsite directly from their wave solder machine.

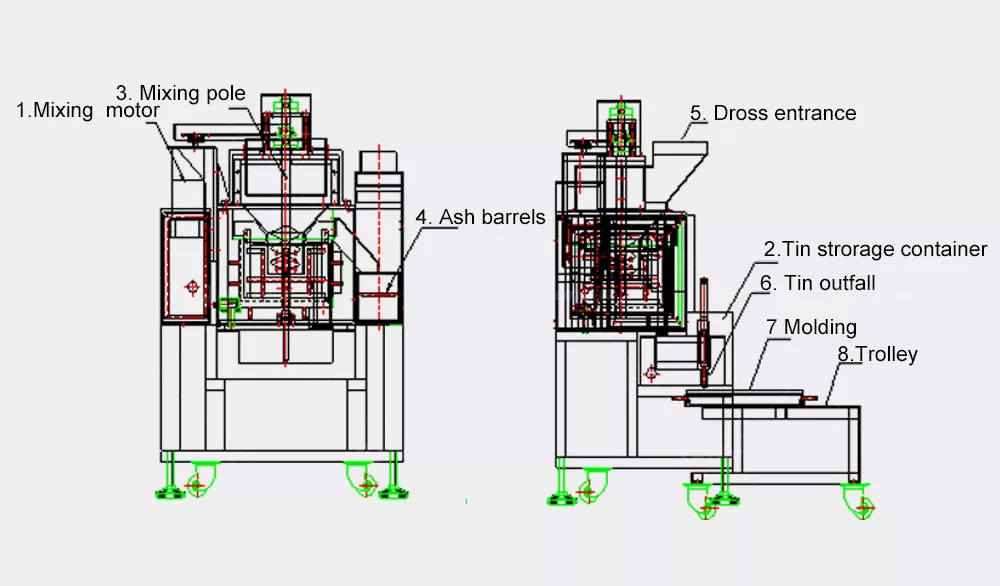

Product

Structure

Product Advantage

Pure physical separation without using any chemicals.

Tin alloy separation rate is up to 98%

The recycled solder bar can be direct use for wave soldering

Compact in size, all stainless steel and is easy to maintain

Patented mixing and separation system for improved separation efficiency

Solder pot is made of corrosion resisting ss 316L material with has a long service life

The unit uses a “U” shape heater covered cast iron heating plate, which will avoid deformation

OMRON temperature controller and SSR relay ensure accurate temperature control and long service life

Machine will alarm when separated solder is in the cabin and reaches the full volume, this indicates to discharge the solder

Details Images

Specification

|

Model

|

GM-SD10

|

|

Mixing motor

|

1φ 220V 90W

|

|

Mixing Capacity of Bottom Tin

|

10KG

|

|

Temperature Scope

|

Up to 350℃

|

|

Heating-up time

|

30MIN

|

|

Feeding time

|

Continuous5-20kg/15min

|

|

Dimension

|

500(L) * 250(W) * 600(H)

|

|

Totol Power Consumption

|

2KW

|

|

Normal running power

|

0.6KW

|

|

Power

|

1φ220V 50Hz

|

|

Net Weight

|

Appro*45kg

|

|

Model

|

GM-SD20

|

|

Mixing motor

|

1φ 220V 90W

|

|

Mixing Heating Power

|

3.8KW

|

|

Mixing Capacity of Bottom Tin

|

60KG

|

|

Temperature Scope

|

Up to 450℃

|

|

Heating-up time

|

50MIN

|

|

Feeding time

|

Continuous5-20kg/15min

|

|

Dimension

|

760(L) * 620(W) * 780(H)

|

|

Totol Power Consumption

|

4KW

|

|

Normal running power

|

2KW

|

|

Power

|

1φ220V 50Hz

|

|

Net Weight

|

Appro*85kg

|

Product packaging

Hot Searches