- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110-380V, accroding to your standard

-

Power:

-

Can be customized

-

Dimension(L*W*H):

-

12*3*3m, can be customized

-

Warranty:

-

1 year

-

Product Name:

-

Hanger nickle barrel plating chrome line automatic machine

-

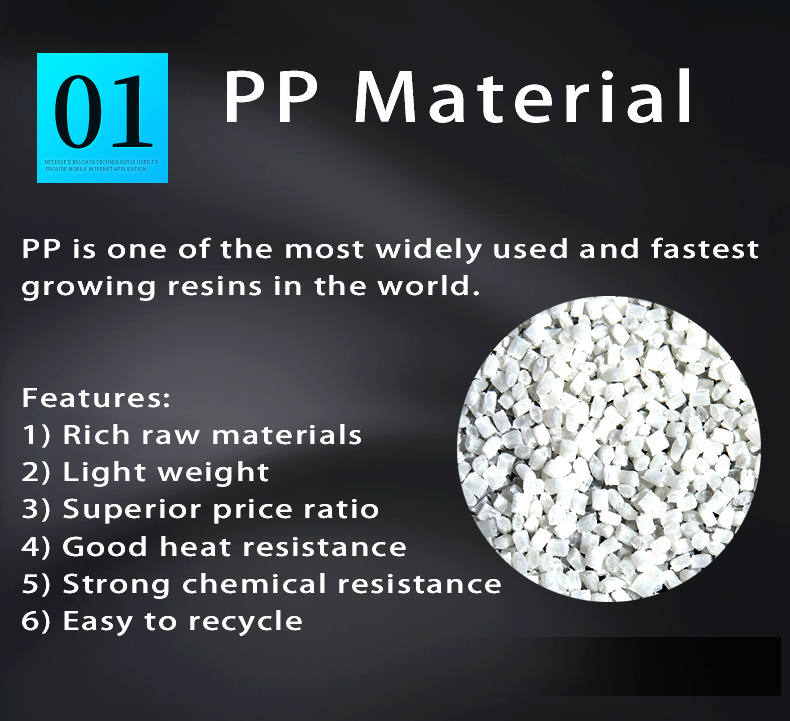

Material:

-

PP material, Tank, Rectifier, Dryer, Barrel

-

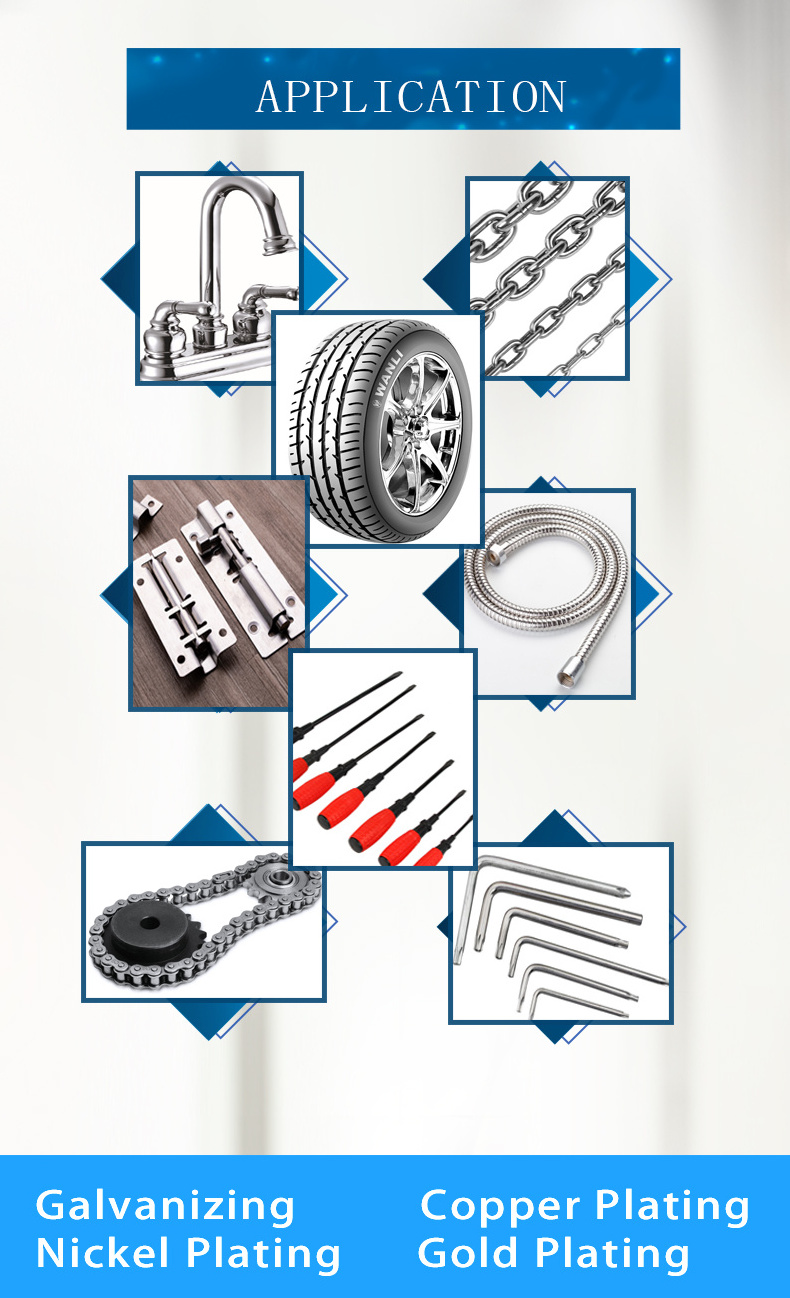

Coatings:

-

Galvanizing, Copper plating, Nickel plating, Gold plating

-

Available for:

-

Metal Surface Plating

-

Heating model:

-

Electric Heating

-

Operation:

-

Automatic

-

Application:

-

Surface Treatment

-

OEM Service:

-

Accept

-

Size:

-

Customer's Reuqest

-

Advantage:

-

Increase productivity

-

Weight:

-

800-2000kg

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

ELECTROPLATING

-

Brand Name:

-

Guangcai

-

Voltage:

-

110-380V, accroding to your standard

-

Power:

-

Can be customized

-

Dimension(L*W*H):

-

12*3*3m, can be customized

-

Warranty:

-

1 year

-

Product Name:

-

Hanger nickle barrel plating chrome line automatic machine

-

Material:

-

PP material, Tank, Rectifier, Dryer, Barrel

-

Coatings:

-

Galvanizing, Copper plating, Nickel plating, Gold plating

-

Available for:

-

Metal Surface Plating

-

Heating model:

-

Electric Heating

-

Operation:

-

Automatic

-

Application:

-

Surface Treatment

-

OEM Service:

-

Accept

-

Size:

-

Customer's Reuqest

-

Advantage:

-

Increase productivity

-

Weight:

-

800-2000kg

-

Certification:

-

ISO9001

| Product Name | Hanger nickle barrel plating chrome line automatic electroplating machine |

| Usage | Metal Surface Plating |

| Material | PP plate, Motor, and so on |

| Heating source | Electricity |

| Performance | High efficiency (> 90%) |

| Feature | High production efficiency, uniform plating |

| Application | Galvanizing, Copper plating, Nickel plating, Gold plating |

| Size | Can be customized |

| Volume | According to your application performance |

| Warranty time | 1 year |

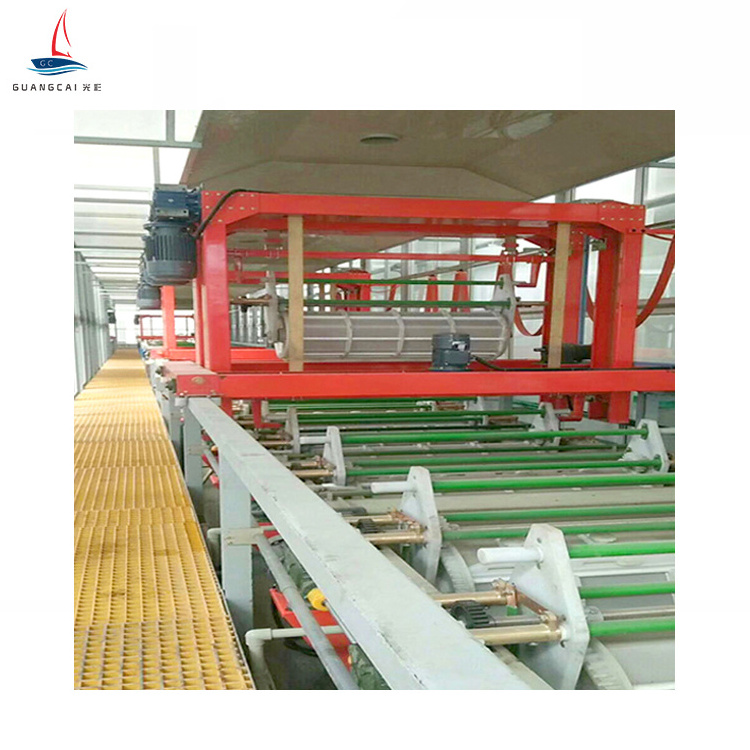

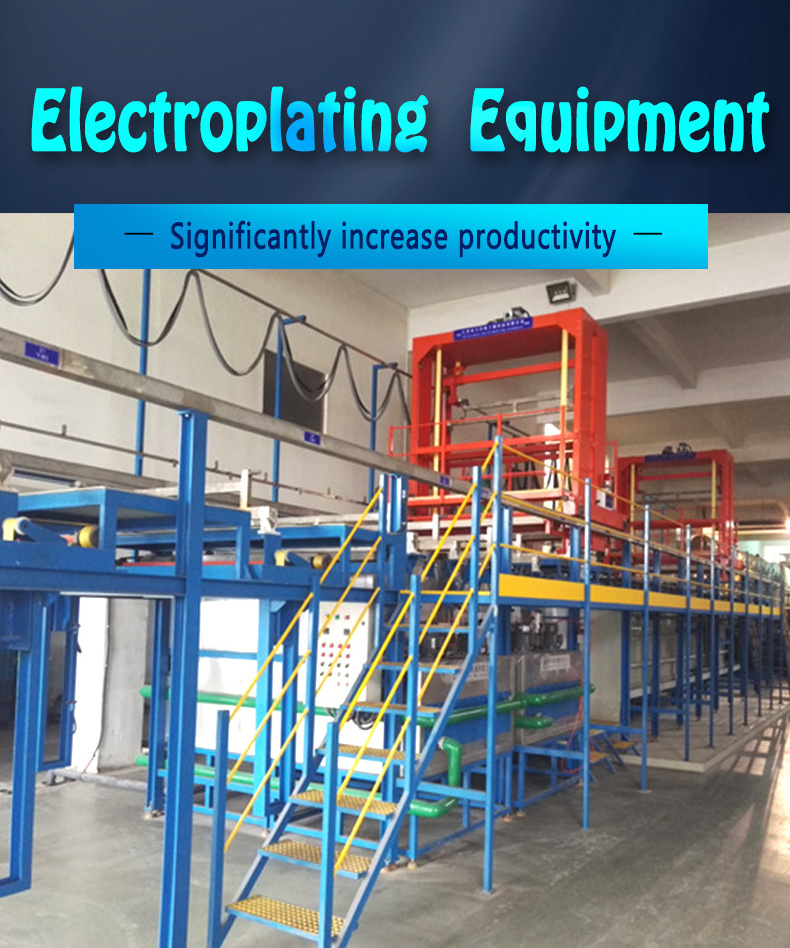

Fully automatic production line

The fully automatic electroplating production line is suitable for products with relatively single products and large output, such as aluminum alloy wheel housings or bicycle rims. The automatic production line for electroplating with these products is designed according to the size and output of the products, so it is very suitable. The loading method of the product and the relatively fixed action tempo can be continuously and automatically produced after the plating solution is strictly managed and the operation program is programmed. The control system of the fully automatic electroplating production line adopts the PLC control machine, and the determined process flow is programmed into the computer, which can be fully automatic controlled.

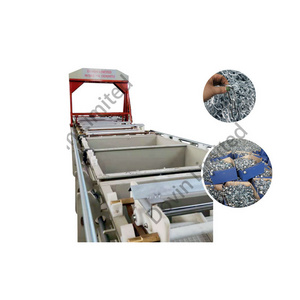

Plastic plating production line

Plastic plating is widely used in automotive decorative parts, mobile phone decorative parts and signage industries. With the expansion of engineering plastics, the scope of plastic plating is also expanding, mainly for the electroplating of ABSPC plastic products.

First, a special treatment method is used on the basic surface of the plastic to obtain a metal layer, which combines the advantages of both plastic box metal, plastic metallization, and then conventional plating.

The metalized plastic overcomes many defects of the plastic itself, and has good solvent resistance, corrosion resistance, wear resistance, light resistance, thermal conductivity, good metal appearance, and hardness of the coating.

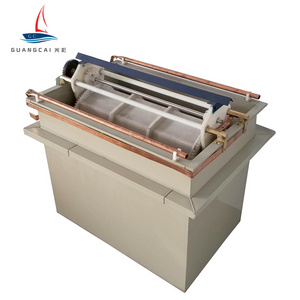

Ring production line

The circular vertical lifting plating line is very different from the ordinary plating line structure. The traverse and lifting of the work-piece are no longer carried out for a single groove, but the entire line of the hanger and the work-piece move simultaneously, and the single groove When the work-piece is ascending, traversing, and descending, it enters the next slot. The work-piece in the plating tank and the multi position tank is continuously moved in the tank without lifting.

The traverse of the work-piece is realized by the motor driving the chain and the chain dragging the track. The lifting of the work-piece is also driven by the motor to drive the chain. The chain drives the lifting platform to hold the slider, the boom, the hanger and the work-piece for up and down movement. All movements and safety protections are controlled by sensors. With certain settings, special procedures such as multiple sets of procedures, air dripping, job hopping, and falling to high positions can be realized.

Linyi Guangcai Metal Surface Technology Co., Ltd. was established in 1999, specializing in the research and development and manufacture of electroplating equipment. Our products include fully automatic, semi-automatic, manual plating equipment and other metal surface treatment equipment and auxiliary equipment, and we have professional electroplating technicians to ensure that all products meet international quality standards. Because we can meet the different needs of our customers, our company is highly valued by different markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We value the quality of our products, pay more attention to our brands and services, and look forward to being your next business partner. Let us make the world a better place!